How Does a 2 Layer 20z PCB Differ from Standard PCBs in Terms of Performance?

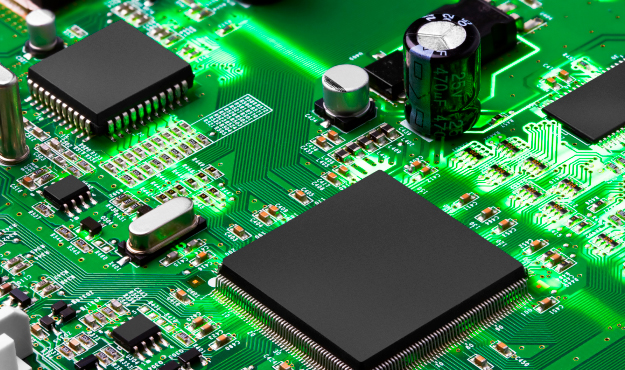

PCBs are the foundation of nearly all electronic devices, and understanding their performance characteristics is critical for businesses and consumers alike. 2 layer 20z PCBs are a special choice that offers distinct advantages over standard PCBs, particularly in terms of electrical performance, durability and thermal management. But how exactly do these two types of PCBs differ? In this blog post, we’ll take a closer look at the unique features and benefits of 2 layer 20z PCB, focusing on how these attributes impact overall performance.

How 2 layer 20z PCBs Improve Electrical Performance?

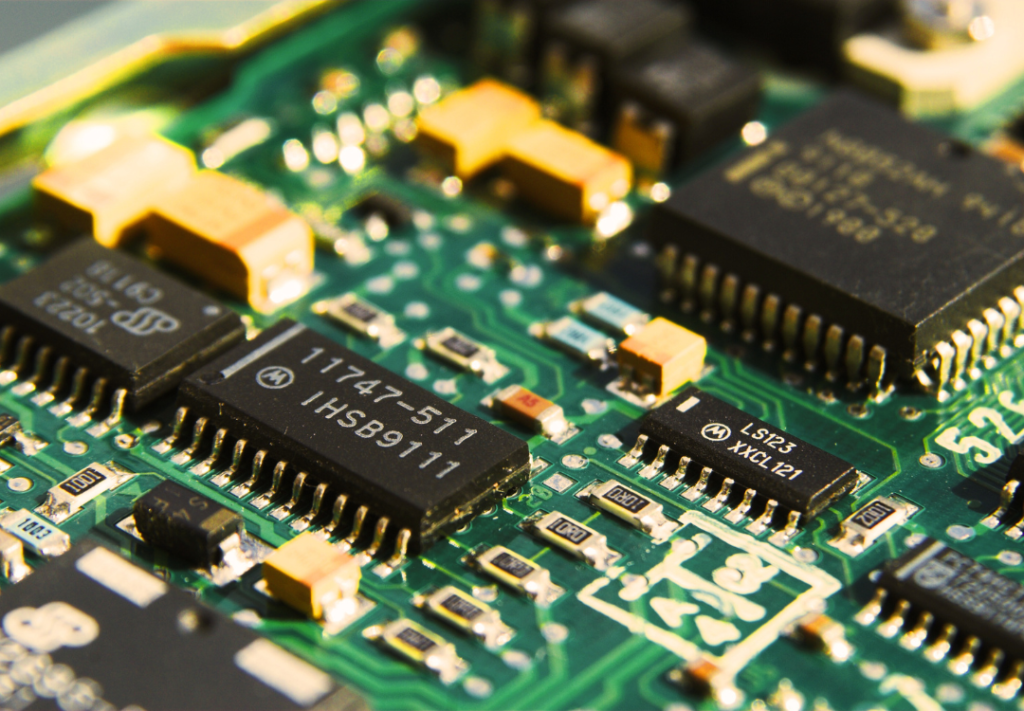

One of the most important aspects of a 2 layer 20z PCB’s superiority over a standard PCB is its electrical conductivity. This thicker copper layer greatly improves the PCB’s ability to carry higher currents. In contrast, standard PCBs typically have thinner copper layers, usually in the 1oz or 2oz range. For applications that require large amounts of current, 2 layer 20z PCBs offer superior performance due to their lower resistance and better current handling capabilities.

The enhanced conductivity of a 2 layer 20z PCB reduces power loss and heat generation, both of which are critical to the long-term reliability of electronic systems. Additionally, the increase in thickness allows for wider or thicker traces, ensuring that electrical signals remain stable even under heavy loads.

Superior Heat Dissipation of 2 layer 20z PCBs

Thermal management is another area where 2 layer 20z PCBs excel. In high-power electronic systems, thermal management is critical to maintaining the performance and longevity of the device. The thicker copper layers in 2 layer 20z PCBs allow for better heat dissipation, as the increased copper surface area can effectively conduct heat away from critical components. Standard PCBs, with their thinner copper layers, often experience thermal issues in high-power applications because they have a poorer ability to transfer and dissipate heat.

The enhanced thermal management capabilities of 2 layer 20z PCBs are particularly important in industries such as automotive, aerospace, and telecommunications, where equipment must continuously operate under extreme conditions. Excessive heat can lead to component failure, reduced efficiency, and, in some cases, even the collapse of the entire system. By using 2 layer 20z PCBs, manufacturers can mitigate these risks.

Mechanical Strength and Durability Comparison

Mechanical strength and durability are key considerations when selecting PCBs, especially in applications involving harsh environmental conditions or physical stress. 2 layer 20z PCBs have a significant advantage in this regard due to their thicker copper layers. The increased thickness provides enhanced mechanical rigidity, making the PCB more resistant to physical damage such as bending, vibration, or shock.

Standard PCBs have thinner copper layers and are generally more susceptible to damage under the same conditions. Over time, repeated mechanical stress can cause cracks, delamination, or other forms of PCB failure, especially in harsh environments. In contrast, the sturdy construction of 2 layer 20z PCBs ensures longer service life and more stable performance.

Design Flexibility with 2 layer 20z PCBs

Design flexibility is another big advantage of choosing 2 layer 20z PCBs. Thicker copper layers give engineers more freedom when designing complex circuits, as they can handle higher currents and more complicated wiring patterns without compromising performance.

In contrast, standard PCBs typically require wider traces or additional layers to achieve similar performance, which increases the size, complexity, and cost of the board. Using a 2 layer 20z PCB, manufacturers can achieve the same performance in a more compact and economical design.

Cost efficiency and advantages are more obvious.

While the performance advantages of 2 layer 20z PCBs are obvious, it is also important to consider the cost impact. The thicker copper layers used in 2 layer 20z PCBs make them more expensive to manufacture than standard PCBs, which use less material and require fewer processing steps.

When comparing the total cost of ownership, 2 layer 20z PCBs may actually be more cost-effective than standard PCBs. For example, in high-power applications, the superior thermal management and electrical performance of 2 layer 20z PCBs can extend the life of the equipment, reduce the need for cooling systems, and avoid expensive repairs or replacements. In addition, the improved durability of 2 layer 20z PCBs can minimize downtime and maintenance costs.

Why 2 layer 20z PCBs are ideal for high-performance applications?

For applications where reliability and longevity are critical, 2 layer 20z PCBs offer clear advantages over standard PCBs. The combination of thicker copper layers, superior thermal management, and enhanced mechanical strength make 2 layer 20z PCBs a reliable choice for industries that require long-term, stable performance. Whether in aerospace systems, automotive electronics, or industrial control systems, 2 layer 20z PCBs can withstand the rigors of continuous operation in demanding environments.

Standard PCBs, while suitable for less demanding applications, may not provide the same level of long-term reliability, especially in high-power or high-stress environments. The thinner copper layers and lower thermal capacity of standard PCBs can lead to premature failures, increased maintenance costs, and shortened product life.

Better Environmental Protection and Sustainability

In today’s environmentally conscious market, sustainability is an increasingly important consideration for manufacturers and consumers alike. With their increased durability and longer lifespan, 2 layer 20z PCBs can contribute to more sustainable electronics by reducing the need for frequent replacements and minimizing electronic waste. While the thicker copper layers of 2 layer 20z PCBs require more raw materials to produce, the overall environmental impact may be lower given the reduced need for maintenance, repairs, and replacements over time.

On the other hand, standard PCBs may need to be replaced more frequently, especially in high-power or high-stress applications, which can lead to increased waste and a larger environmental footprint.

2 layer 20z PCBs outperform standard PCBs

In summary, 2 layer 20z PCBs offer many performance advantages over standard PCBs, from enhanced conductivity and superior thermal management to greater mechanical strength and design flexibility; 2 layer 20z PCBs outperform standard options in nearly every key performance area. While the initial cost may be higher, the long-term benefits of reliability, durability, and efficiency make 2 layer 20z PCBs a wise investment for those who demand the best performance from their electronic systems.