What are the advantages of using SSD PCB in automotive applications?

In today’s automotive landscape, integrating advanced technologies is essential to improve performance, safety, and efficiency. SSD PCB is an innovation that has become a game-changer in automotive applications. This blog post explores the many benefits of using SSD PCBs in vehicles.

Enhanced Performance and Speed in Vehicles

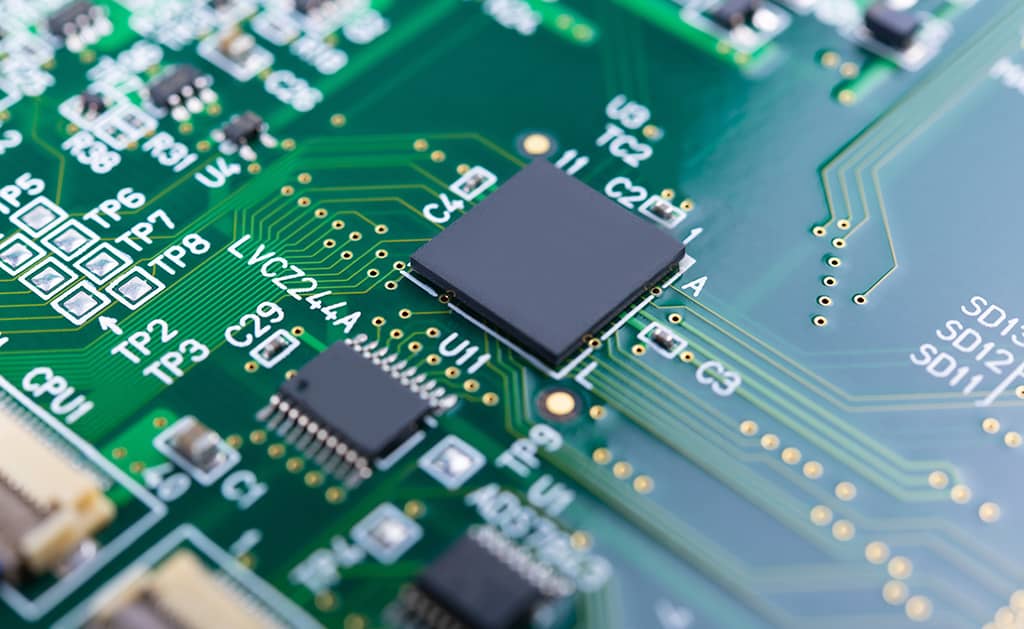

The primary benefit of SSD PCBs in automotive applications is their ability to improve performance and speed significantly. SSDs use flash memory, unlike traditional hard drives, allowing faster data access and retrieval. This speed is critical in modern vehicles, as navigation, infotainment, and advanced driver assistance systems rely on quick data processing. By implementing SSD PCBs, automakers can ensure that their vehicles provide a seamless user experience, minimize latency in system response times, and improve overall functionality.

In addition, SSD PCBs’ high-speed capabilities enable real-time data analytics, which is essential for various automotive features, including predictive maintenance and dynamic route optimization. As vehicles increasingly rely on data-driven technology, SSD PCBs’ role becomes even more important, setting a new standard for automotive performance.

Improved Reliability and Durability in Vehicles

Reliability and durability are critical in automotive applications. SSD PCBs are designed to withstand the extreme conditions often encountered in vehicles, such as temperature fluctuations, vibration, and moisture. Unlike traditional hard drives, which contain moving parts that can fail over time, SSDs have no mechanical parts and are less susceptible to physical damage.

The rugged design of SSD PCBs ensures that they can operate effectively under various environmental stresses, thereby extending the life of automotive systems. This reliability is critical in critical applications such as braking systems, engine control units, and safety features, where any failure can have serious consequences. By integrating SSD PCBs, manufacturers can give consumers greater peace of mind about the performance and safety of their vehicles.

Enhanced Energy Efficiency and Sustainability in Vehicles

SSD PCBs’ energy efficiency is a significant advantage in an increasing concern for sustainability. Compared to traditional hard drives, these boards consume less power, helping to improve vehicle fuel efficiency. Reduced energy consumption is good for the environment and saves consumers money, as it can reduce fuel expenses.

In addition, SSD PCBs’ compact design can more effectively use space within automotive systems, allowing manufacturers to create lighter, cleaner vehicles. The reduction in weight further improves fuel efficiency and overall performance, which is in line with the industry’s pursuit of green technology. As consumers increasingly prioritize environmentally friendly choices, SSD PCB offers a compelling solution for automotive applications.

Enhanced Security Features in Automotive

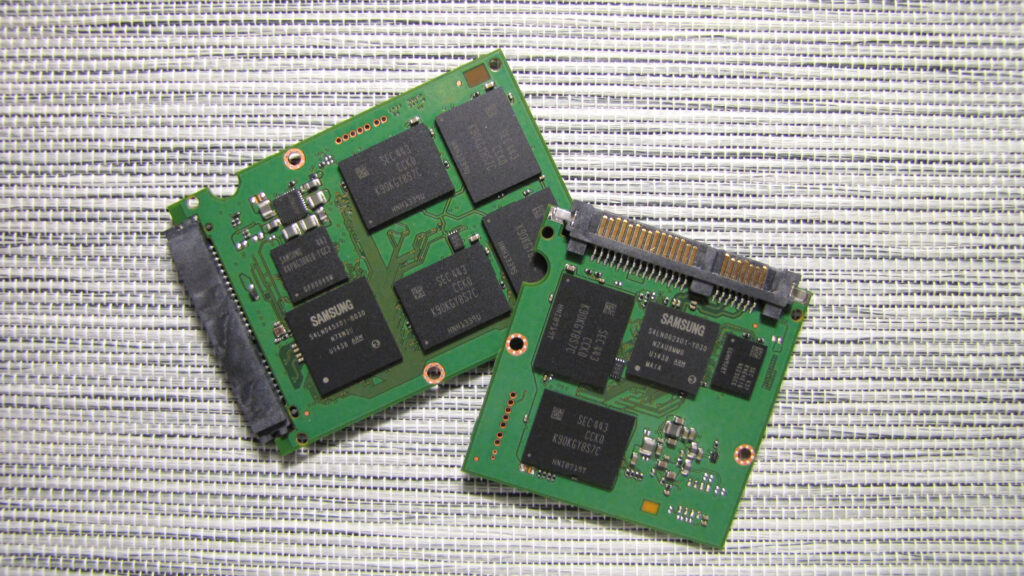

Security is a critical issue in the automotive industry, especially with the rise of connected cars. SSD PCB offers advanced security features that are essential for protecting sensitive data. Many SSDs feature encryption to protect information such as user profiles, navigation data, and vehicle performance metrics from unauthorized access.

By using SSD PCB, automakers can enhance the security of their vehicles, addressing consumer concerns about data privacy and cyber threats. Additionally, the ability to securely store data helps improve the overall reliability of automotive systems, as critical information can be securely maintained and accessed when needed. This focus on security protects consumers and strengthens the brand’s reputation in an increasingly competitive market.

Scalability and Flexibility of SSD PCB

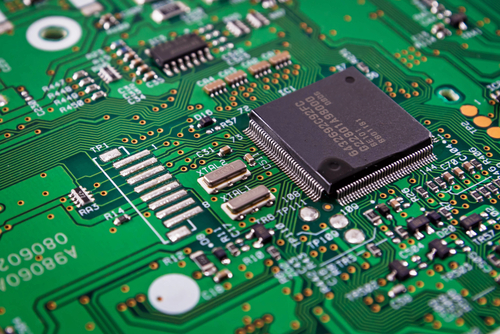

The automotive industry is rapidly evolving, constantly introducing new technologies and features. The scalability and flexibility offered by SSD PCB are essential to accommodate these advancements. As manufacturers seek to integrate more complex systems, such as autonomous driving features and advanced infotainment options, the need for adaptable storage solutions becomes apparent.

SSD PCBs can be easily upgraded or expanded, allowing automakers to keep pace with technological advances without overhauling the entire system. This adaptability ensures that vehicles remain relevant and competitive in a rapidly changing market, providing consumers with the latest features and innovations. In addition, Customizing SSD PCB for specific applications enhances the versatility of automotive design, meeting a wide range of consumer preferences and demands.

Long-term Cost Benefits of SSD PCB

While the initial investment in SSD PCB may be higher than traditional hard drives, the long-term cost benefits are undeniable. SSDs’ durability and reliability can reduce maintenance and replacement costs. In addition, their energy efficiency can help reduce operating costs, further enhancing their value proposition for automotive applications.

the increased performance and speed offered by SSD PCB can increase user satisfaction, leading to higher sales and customer loyalty for automakers. In a competitive industry where consumer preferences are constantly changing, the ability to offer vehicles equipped with advanced technologies, such as SSD PCBs, can significantly enhance a brand’s market position.

SSD PCB: The Future of Automotive Technology

As the automotive industry moves increasingly toward a digital future, the role of SSD PCBs will only continue to grow. The need for faster, more reliable, and more energy-efficient storage solutions will drive innovation in SSD technology, enabling new applications and capabilities.

This shift means consumers can get cars that not only meet current needs but are also ready for the future. As connected car technology and features like autonomous driving become more mainstream, integrating SSD PCBs will be critical to ensure these systems operate seamlessly and efficiently.