How do you ensure precision in SSD PCB layer alignment?

The rapid development of solid-state drives has made precision engineering a cornerstone of their manufacturing. At the heart of every high-performance SSD is a carefully designed printed circuit board that houses the key components that drive data storage and processing. Ensuring accurate layer alignment is critical to reliability, performance, and durability among the many aspects of SSD PCB production. Layer alignment refers to the precise positioning of multiple PCB layers to ensure seamless connectivity and functionality. Even slight misalignments can result in electrical inconsistencies, reduced data transfer speeds, or compromised durability. Next, we will discuss the tips, techniques, and quality controls used to achieve SSD PCB layer alignment accuracy.

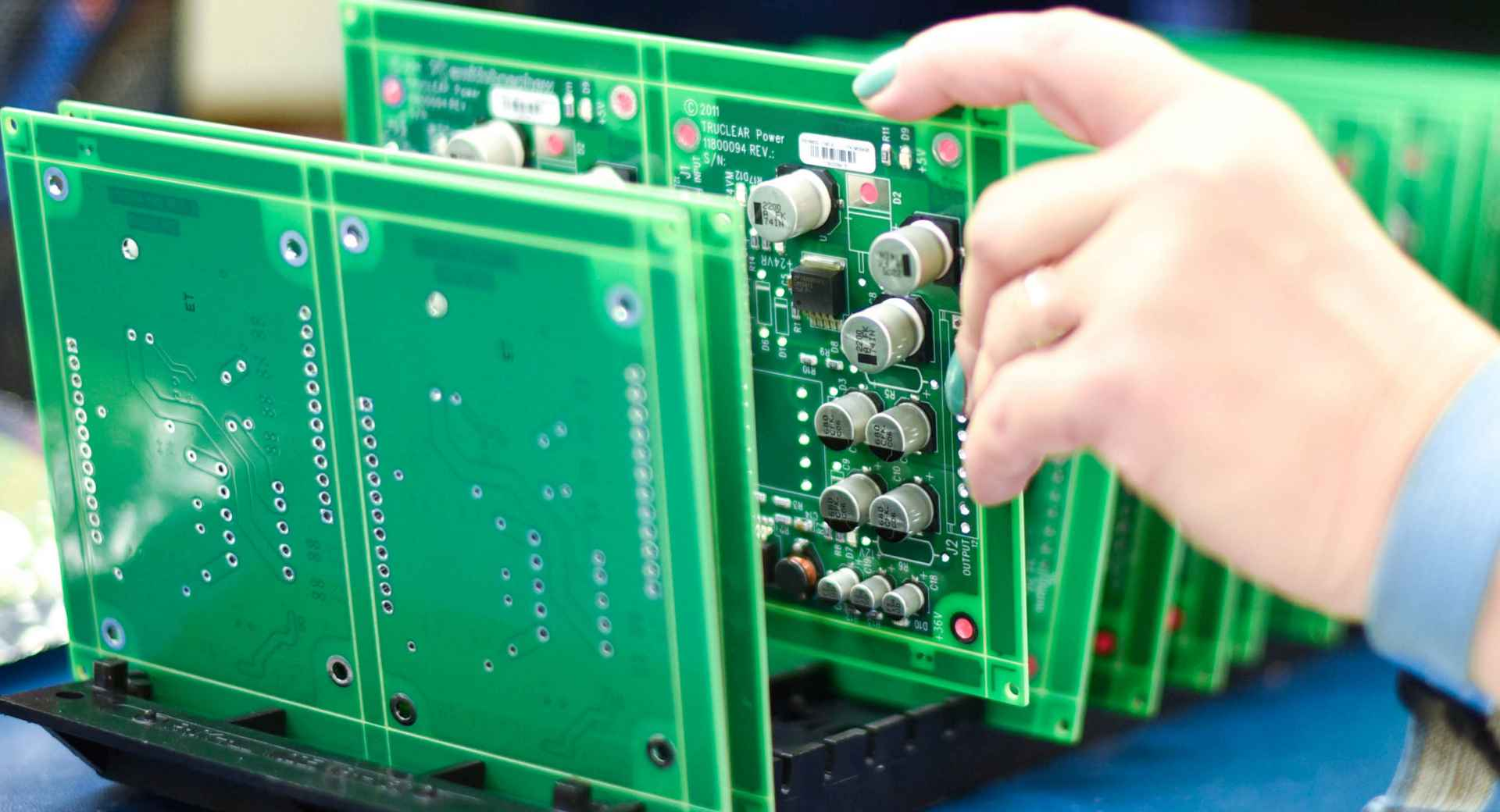

Understanding Multilayer Structure in SSD PCB

SSD PCBs are typically multilayered, comprising several conductive and insulating layers. Each layer performs a distinct function—some carry electrical signals, while others distribute power or provide grounding. The alignment of these layers is crucial to ensuring that electrical signals travel efficiently without interference or loss.

Advanced lamination techniques are used to achieve this. During lamination, the layers are bonded under high pressure and temperature. Misalignments, even as small as a few microns, can lead to overlapping vias or misconnected traces, impacting the PCB’s overall performance.

For SSD PCBs, where space constraints are significant and the demand for high-speed operations is constant, precise alignment is non-negotiable. Manufacturers utilize sophisticated alignment systems to meet these critical requirements and conduct thorough inspections to ensure all layers are positioned perfectly. Consequently, this attention to detail ensures optimal performance and reliability, even under the most demanding conditions.

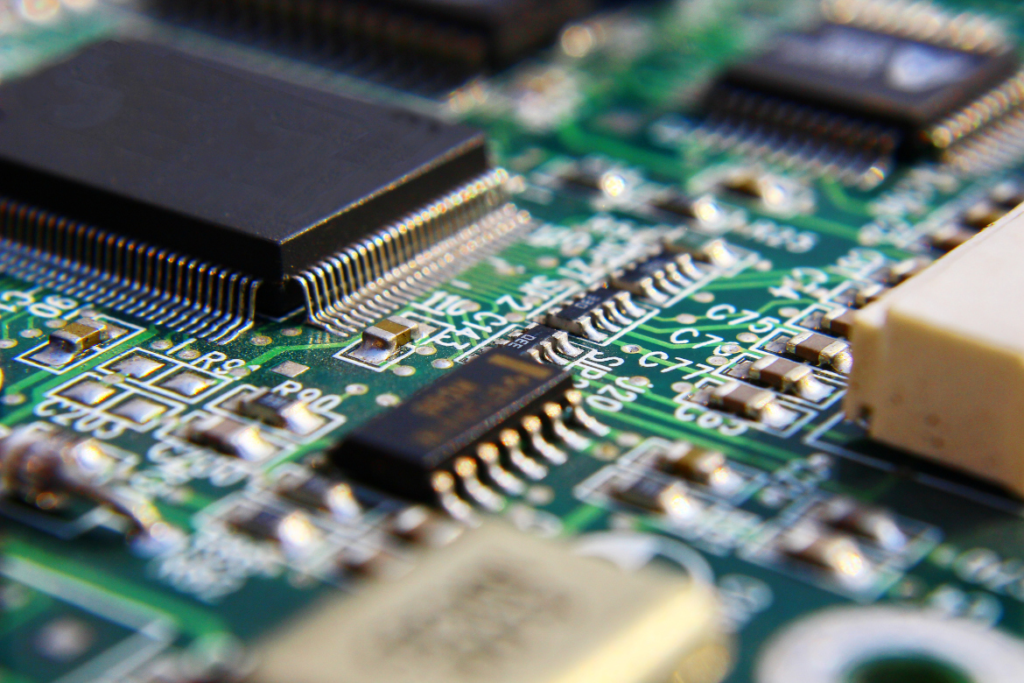

High-precision equipment enables more precise alignment.

Advanced manufacturing equipment is one of the most critical factors in achieving precision. High-resolution optical alignment systems align the PCB layers with sub-micron accuracy. These systems use cameras and lasers to detect even the slightest deviations, ensuring perfect positioning during the lamination process. Using such high-precision equipment is crucial in achieving the accuracy required in SSD PCB manufacturing.

Another crucial technology is Automated Optical Inspection (AOI), which verifies the alignment of each layer after lamination. AOI systems use powerful algorithms to detect misalignments. These systems capture high-resolution images of the PCB and compare them to the design specifications, ensuring that only perfectly aligned PCBs move forward in the production process.

In addition, precision drilling machines create vias—tiny holes connecting different PCB layers. These machines ensure that the vias align perfectly with the corresponding traces, maintaining the integrity of electrical connections.

Material Selection and Its Impact on Mid-Layer Alignment

The materials used in SSD PCBs play a significant role in achieving precise layer alignment. High-quality substrates like FR4 or polyimide are chosen for their dimensional stability. These materials resist warping or expansion during lamination, maintaining consistent alignment across all layers.

Copper is commonly used for the conductive layers due to its excellent electrical and thermal properties. The thickness of the copper layers is carefully controlled to ensure uniformity, which is critical for alignment. Variations in copper thickness can cause uneven pressure during lamination, leading to misalignment.

Additionally, using specialized bonding materials, such as prepregs, ensures that the layers adhere evenly without shifting. The thermal properties of these materials are optimized to withstand the high temperatures of the lamination process without causing distortion.

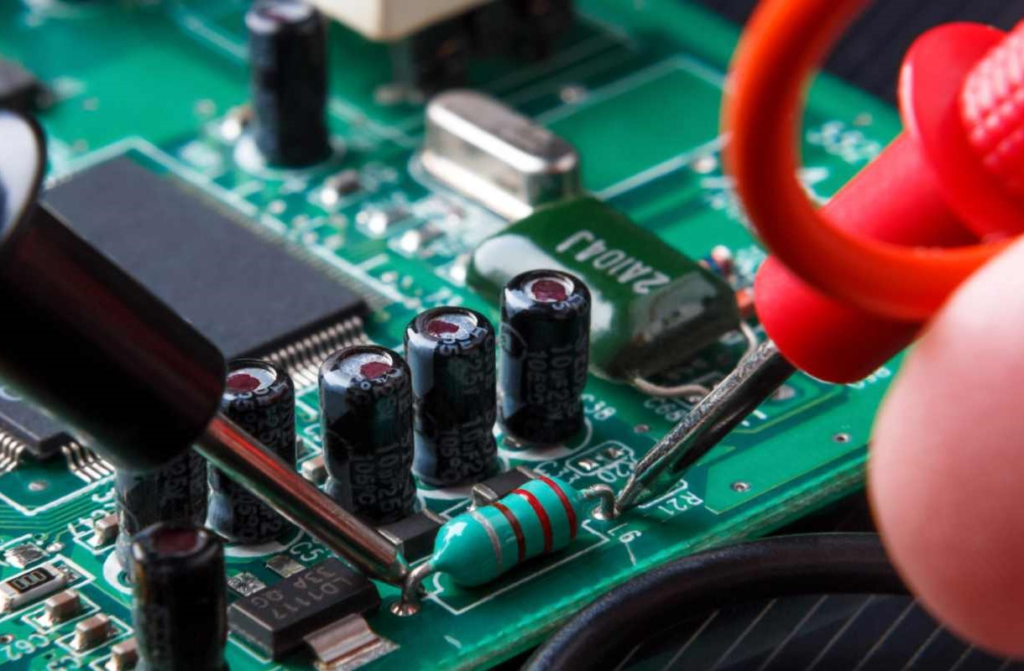

Quality Control Processes in SSD PCB Manufacturing

To ensure precision in layer alignment, rigorous quality control processes are implemented at every stage of SSD PCB production. For instance, these processes begin with pre-lamination checks, during which each layer is inspected for dimensional accuracy and alignment markers. This commitment to quality control guarantees precise alignment and ensures the final product’s overall reliability.

Post-lamination, X-ray inspection is used to verify the alignment of internal layers. Specifically, X-rays provide a noninvasive method of examining the PCB’s internal structure, ensuring all layers are correctly aligned and defects-free.

Another critical quality control measure is impedance testing, which verifies the electrical performance of the PCB. Misalignments can cause variations in impedance, impacting signal integrity. Manufacturers can identify and rectify alignment issues early in production by conducting these tests.

Case Study: Precision in SSD PCB for Gaming Consoles

A leading gaming console manufacturer faced performance bottlenecks during testing caused by misaligned SSD PCB layers. These alignment issues disrupted signal integrity, reducing data transfer speeds and compromising the gaming experience.

Our team stepped in to develop highly precise SSD PCBs using automated optical alignment systems and advanced X-ray inspections to ensure layer accuracy within micrometer tolerances. We improved signal integrity and heat dissipation by combining low-dielectric materials with optimized stack-up designs to enhance performance further. These advancements provide the reliability and efficiency required for high-performance SSD applications.

After implementation, the revamped SSD PCBs delivered ultra-fast loading times and seamless gameplay. Post-launch, the console received widespread acclaim for its performance, underscoring the critical role of precise layer alignment in achieving high-speed reliability for consumer electronics.

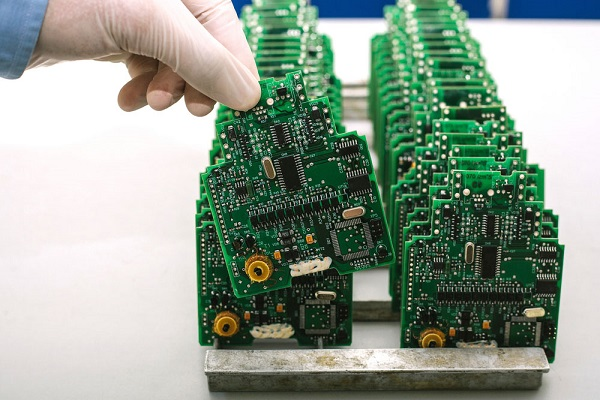

The Role of Automation in Ensuring Alignment Accuracy

Automation plays a pivotal role in maintaining precision during SSD PCB production. Automated systems reduce human error and ensure consistent quality across large production volumes. Every process step, from optical alignment systems to automated drilling and inspection machines, is optimized for accuracy.

Machine learning and AI are also being integrated into the production process. These technologies analyze data from previous production runs to identify patterns and predict potential alignment issues, allowing manufacturers to make proactive adjustments.

Automation enhances precision and efficiency, enabling manufacturers to produce high-quality SSD PCBs at competitive costs.

Precision as the Cornerstone of SSD PCB Manufacturing

Layer alignment precision is a fundamental aspect of SSD PCB manufacturing, directly impacting the final product’s performance, reliability, and durability. Manufacturers ensure that every SSD PCB meets the highest precision standards using advanced equipment, high-quality materials, and rigorous quality control processes.