What factors affect the performance of an SSD PCB?

SSDs have become essential to modern computing, offering faster performance, better reliability, and greater energy efficiency than traditional hard drives. The SSD PCB is at the heart of an SSD, a key component that connects and supports the SSD memory chip, controller, and other key elements. In this blog post, we will explore the key factors that affect SSD PCB performance.

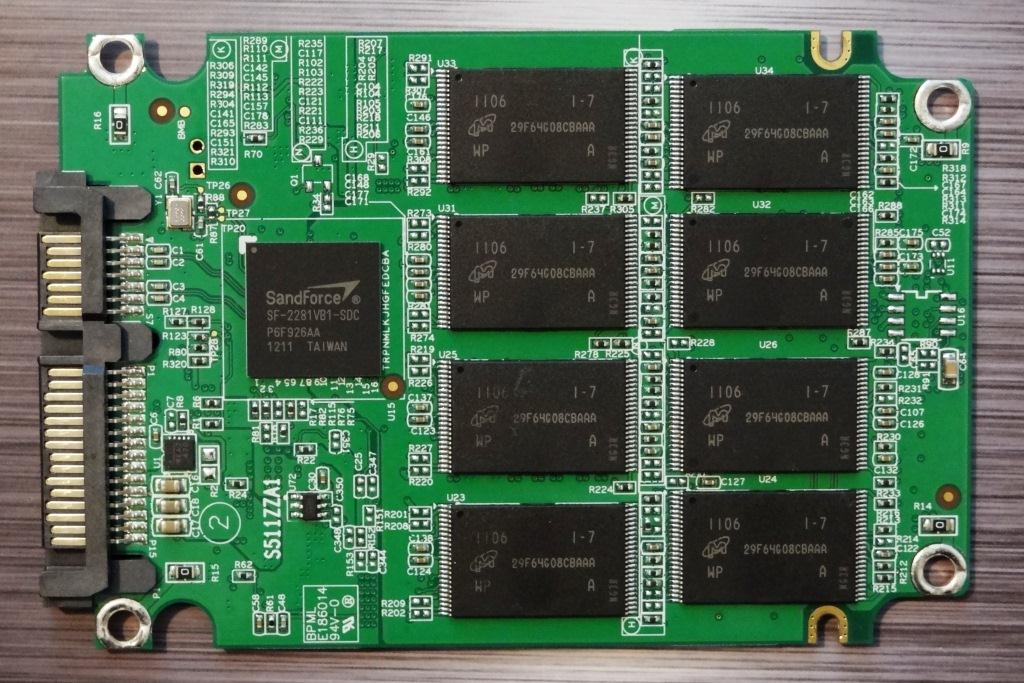

The Role of the SSD Controller in PCB Performance

One of the most critical factors that affect SSD PCB performance is the quality and functionality of the SSD controller. The SSD controller is the brain of the SSD and is responsible for managing data transfer between the storage memory (NAND flash) and the computer’s system. A powerful controller can significantly improve the overall performance of the SSD PCB.

Modern SSD controllers support features such as wear leveling, error correction, and encryption, all of which help improve the reliability and lifespan of the SSD. The more advanced the controller, the better the performance and durability of the SSD PCB. In addition, the number of channels in the controller also affects the SSD’s performance. Controllers with more NAND channels can read and write data faster, thereby increasing the speed of the SSD PCB. High-performance SSDs with PCIe Gen 3 or Gen 4 controllers offer faster data transfer rates, significantly boosting performance.

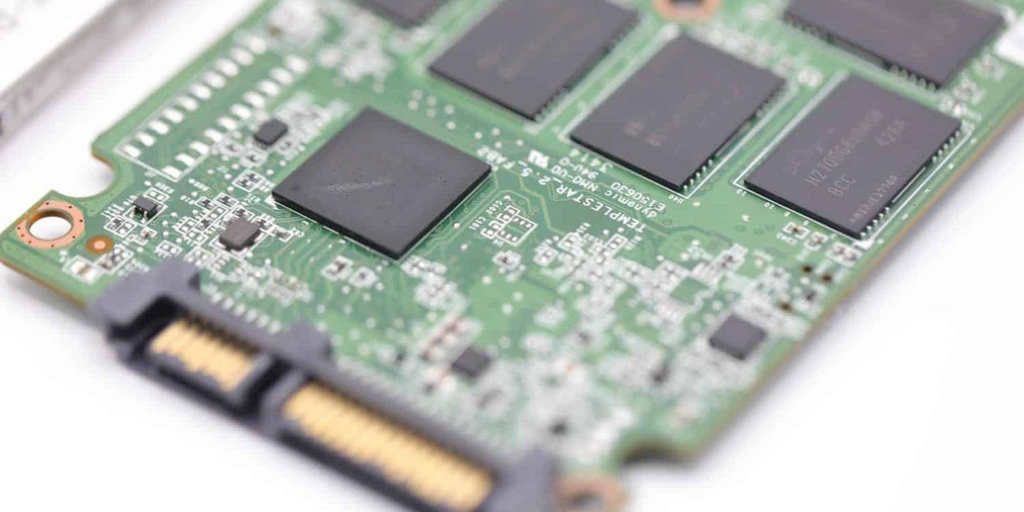

NAND Flash Type and Its Impact on SSD PCB Performance

The type of NAND flash used in the SSD PCB directly affects the device’s performance. NAND flash is the primary storage medium in SSDs, and there are several types to choose from, including SLC, MLC, TLC, and QLC. Each type of NAND flash has different performance characteristics regarding speed, durability, and cost.

SLC flash stores one bit of data per cell and is the fastest, most durable, and most expensive. MLC stores two bits per cell, balancing performance, durability, and cost, making it suitable for consumer-grade SSDs. TLC stores three bits of data per cell, providing higher storage capacity at a lower price but slower write speeds and lower durability than MLC and SLC. QLC stores four bits of data per cell, providing the highest storage capacity, but it reduces performance and lifespan.

The choice of NAND flash type directly affects the overall performance of the SSD PCB. SSDs with SLC or MLC NAND tend to have better write speeds and endurance, while TLC and QLC offer more affordable solutions with higher storage capacities.

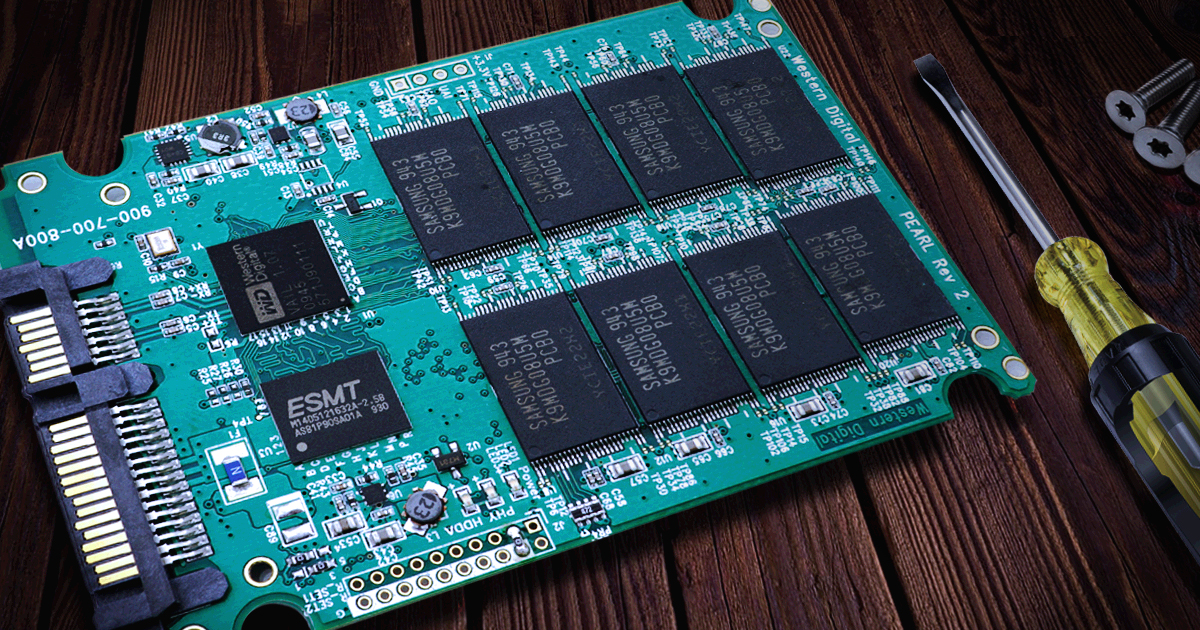

The Importance of PCB Design and Layout

The design and layout of an SSD PCB play a pivotal role in determining its performance. A well-designed PCB ensures that electrical signals are efficiently routed, minimizing interference and maximizing data transfer speeds. The quality of the PPCB’sttracePCB’sing through placement and the use of high-quality materials are key factors that influence the speed and reliability of the SSD PCBs.

Using multi-layer PCBs in SSDs is common because they allow for efficient signal routing and better power distribution. The layers help reduce the oSSD’s overall size while maintaining high performance. Another important consideration is the use of quality materials in the SSD PCB. For example, high-quality copper traces, used for data and power transmission, ensure the signals are transmitted without significant loss. Proper grounding and power planes in the PCB layout are crucial to prevent power noise and reduce data corruption risk.

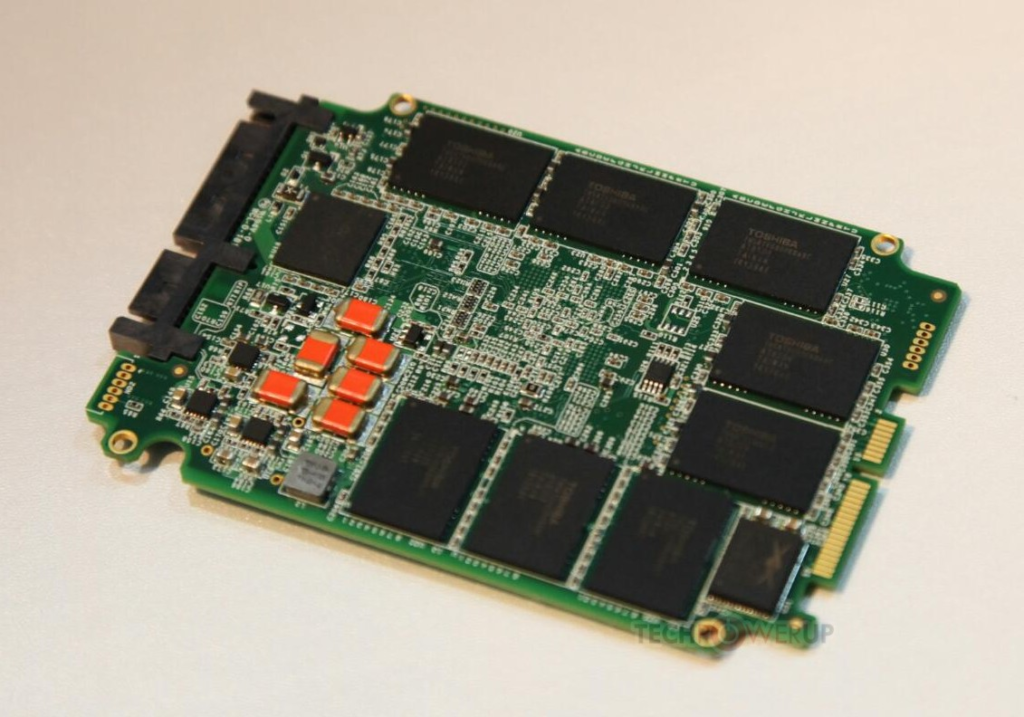

Heat Management and Its Effect on SSD PCB Performance

Heat is one of the primary factors that can degrade the performance of an SSD PCB. As the SSD reads from and writes to the NAND flash, its components generate heat. If not properly managed, this heat can cause the SSD to throttle its performance to prevent overheating, leading to slower data transfer speeds.

Effective heat management in SSD PCBs is achieved through heat sinks, thermal pads, and efficient airflow within the device housing. High-performance SSDs often have dedicated heat sinks to dissipate heat and maintain the SSD PCB’s temperature within an optimal range. SSD PCB performance can degrade over time without proper thermal management, potentially shortening the drive’s lifespan. Excessive heat can degrade NAND flash memory, increasing wear and potentially shortening the SSD’s lifespan.

The Role of Firmware and Software Optimization

Firmware plays an essential role in optimizing the performance of an SSD PCB—the firmware manages how data is written and read from the NAND flash memory. Optimized firmware can enhance wear leveling, error correction, and data security, improving performance and reliability.

Many SSD manufacturers provide firmware updates to enhance the performance of their drives over time. These updates may include improvements in read/write algorithms, optimizations for faster data transfer, and fixes for any potential issues discovered in earlier firmware versions. Users should regularly check for firmware updates to ensure their SSD PCBs run at peak performance.

Power Supply and Voltage Stability

Another factor that affects the performance of an SSD PCB is the power supply and voltage stability. Fluctuations in power can lead to data corruption, reduced performance, or even damage to the SSD’s components. SSDs typically require a stable voltage to ensure the memory chips, controller, and other elements function correctly.

The SSD PCB uses voltage regulators and capacitors to maintain a consistent power supply to the components. Any instability in the power supply can cause the SSD to operate erratically, leading to slower read/write speeds or even complete failure. High-quality SSD PCBs incorporate advanced power management solutions to ensure that the SSD operates efficiently and reliably under various conditions. When choosing an SSD, consumers should ensure that their system provides a stable power source to prevent performance degradation. High-end SSDs often include power-loss protection circuits to safeguard against outages and prevent data loss.

Environmental Factors and Their Impact on SSD PCB Performance

The environment in which an SSD PCB operates can also significantly affect its performance. Factors such as humidity, vibration, and exposure to contaminants can cause issues with the SSD PCB’s functionaliPCB’sor instance, high humidity levels can lead to corrosion of the PCB components, which can cause electrical malfunctions.

Furthermore, SSD PCBs used in harsh environments, such as industrial settings or transportation, need to be built with extra durability. Manufacturers often use protective coatings and robust enclosures to shield the SSD PCB from environmental factors that could impact its performance. In applications where reliability is critical, such as in medical devices or aerospace, SSDs are often designed to meet specific environmental standards to ensure long-term performance.

Comprehensive factors affecting SSD performance

While the SSD PCB is vital in determining an SSD’s overall performance, it is only one aspect. Factors such as the SSD controller, NAND flash type, PCB design, thermal management, firmware optimization, power supply stability, and environmental conditions can all affect the SSD’s ultimate performance and reliability.