How does a 6 layer SSD PCB contribute to power efficiency in SSDs?

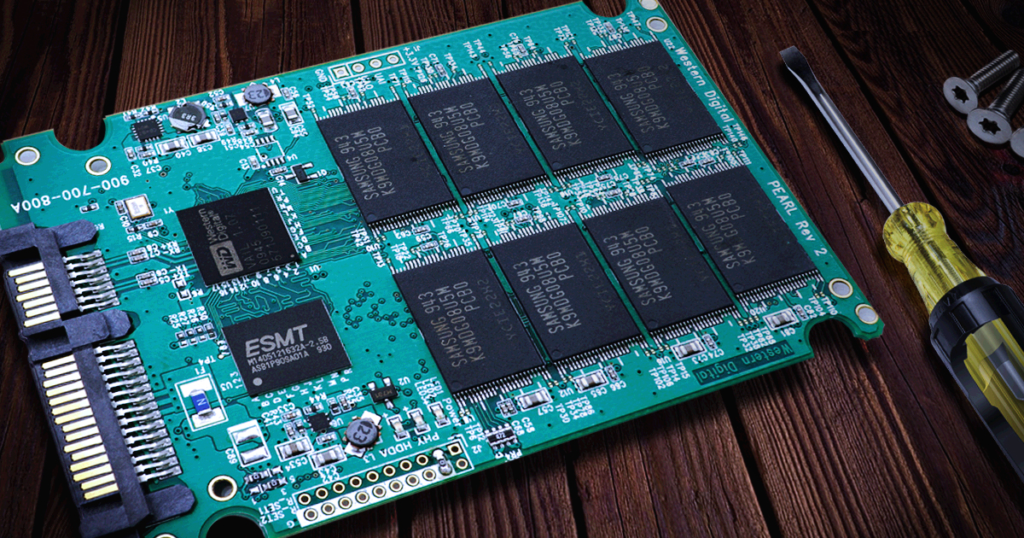

The demand for faster, more reliable, and energy-efficient storage solutions has skyrocketed in computing. SSDs are at the forefront of this technological shift. Unlike traditional HDD), SSDs offer significantly faster read and write speeds, smaller form factors, and lower power consumption. However, power efficiency remains critical, particularly for laptops, mobile phones, and embedded systems that rely on battery life. The key to achieving enhanced power efficiency in SSDs lies in the design and construction of their components. One such component is the 6-layer SSD PCB, which is essential in optimizing the SSD power performance of SSDs. In this article, we will explore how a 6-layer SSD PCB contributes to improving the power efficiency of SSDs, providing businesses and consumers with a deeper understanding of its benefits.

Enhanced Power Distribution for Optimal Efficiency

The first and most direct way a 6-layer SSD PCB contributes to power efficiency is through its ability to provide enhanced power distribution. Power consumption in an SSD is influenced by how electrical signals are routed through the system and how power is distributed across various components like memory chips, controllers, and interfaces. In a 6-layer SSD PCB, the design allows for more efficient power distribution to the critical elements, minimizing losses due to inefficient routing.

A traditional, single-layer PCB often struggles to manage power effectively, requiring complex routing solutions that result in power loss or inefficient signal paths. However, a 6-layer SSD PCB features multiple layers of copper traces, allowing for better separation of power and ground planes. This separation reduces power noise and interference, leading to more stable and efficient power delivery. For example, by strategically positioning the power planes in different layers, the PCB can provide a cleaner power signal to each component, improving overall power efficiency. This leads to less energy wastage and, ultimately, better battery life and thermal performance for SSD devices.

6-layer SSD PCB reduces signal interference and power loss

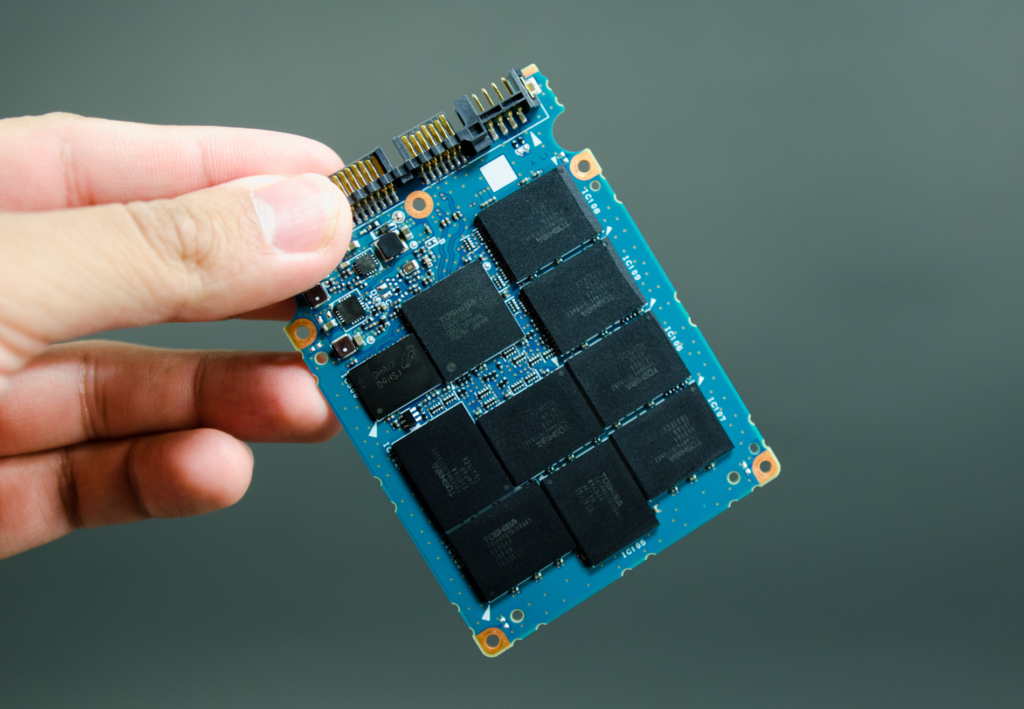

Signal integrity is another critical factor in power efficiency, particularly in high-speed electronic devices like SSDs. As the demand for faster data transfer speeds grows, so does the risk of signal interference and power loss, which can degrade the drive’s performance and power efficiency. A six-layer SSD PCB helps address this challenge by providing more effective shielding and grounding.

In a 6-layer SSD PCB, designers separate signal and power lines, reducing the risk of cross-talk and electromagnetic interference (EMI). The layers in the PCB act as shields that prevent unwanted signals from interfering with the critical data paths, ensuring that the signals transmitted across the board remain strong and stable. The result is a more reliable SSD and a more power-efficient one. The less signal degradation there is, the less power is required to maintain high-speed data transmission. This leads to lower overall power consumption, as less energy is wasted compensating for signal interference.

Thermal Management for Improved Power Efficiency

Heat is an unavoidable byproduct of electronic device power consumption. SSDs process data at high speeds, generating heat that can impact the drive’s power efficiency. Poor thermal management can lead to increased energy consumption and reduced component lifespan. The 6-layer SSD PCB design plays a crucial role in managing thermal performance, which, in turn, optimizes power efficiency.

A 6-layer SSD PCB can better manage heat dissipation by using multiple layers. The copper traces in the PCB effectively spread heat away from sensitive components, ensuring the temperature remains within optimal operating ranges. In addition, using heat sinks or vias within the layers can further enhance the dissipation process. This leads to a cooler operating environment, where components such as memory chips and controllers do not need additional energy to deal with excess heat. As a result, the system maintains energy efficiency even under heavy workloads, leading to better overall power performance.

6-layer SSD PCB supports high-speed data transfer with low power consumption

One key advantage of a 6-layer SSD PCB is its ability to support high-speed data transfer with minimal power consumption. An SSD’s performance depends heavily on how efficiently it can read from and write to the drive. The more complex the data transfer process, the higher the power consumption required to complete the task. A 6-layer SSD PCB handles high-frequency signals with minimal power loss, enabling faster data transfer while maintaining low energy usage.

With 6-layer SSD PCBs, the additional layers allow for optimized routing of high-speed data signals. These extra layers help keep the data paths short and efficient, reducing the time and power required for data transmission. For example, high-speed NAND flash memory and controller chips can communicate with minimal signal degradation, even at peak speeds. As a result, the SSD consumes less power during read/write cycles, improving the overall power efficiency of the drive.

Power Optimization Through Layered Design

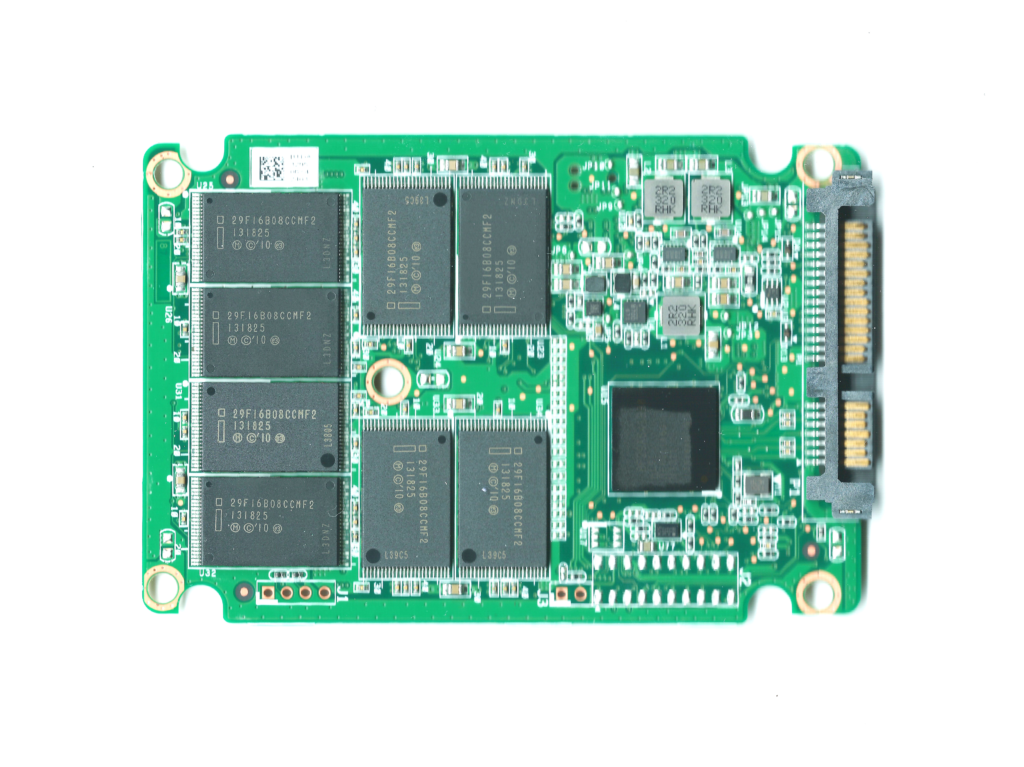

The layered construction of a 6-layer SSD PCB is fundamental to optimizing power consumption. By dividing the PCB into multiple layers, engineers can place the ground, power, and signal traces on separate layers, which enables better control over the flow of electricity throughout the drive. This design minimizes the risk of power loss due to signal interference or inefficiencies in routing.

For instance, power delivery systems in SSDs often require high currents, which can lead to significant energy losses if not managed properly. A 6-layer SSD PCB design provides dedicated planes for power and ground, ensuring that these high currents are delivered efficiently and that the ground planes help stabilize the power flow. This results in less heat generation and reduced power wastage. Additionally, a more efficient power delivery system means that the SSD can operate at higher speeds with lower energy consumption, which is crucial for mobile devices and other battery-powered applications where power efficiency is paramount.

Reducing Power Consumption During Idle States

Power efficiency is about performance during active data transfers and managing power during idle states. Modern devices, especially consumer electronics like laptops, smartphones, and tablets, require low-power idle states to prolong battery life. The 6-layer SSD PCB contributes significantly to achieving low power consumption during idle times by allowing for more efficient power management.

In traditional PCBs, power management during idle states can be inefficient, leading to unnecessary power consumption when the device is inactive. However, with a 6-layer SSD PCB, more advanced power management techniques can be employed. For example, the PCB design can include power gating, which allows individual components of the SSD to be powered down when not in use, significantly reducing overall power consumption. Additionally, by providing more efficient power routing and better voltage regulation, the 6-layer SSD PCB ensures that the power draw remains minimal even during idle periods, extending battery life without sacrificing performance when the system is active.

Enabling High-Performance SSDs with Lower Energy Requirements

The 6-layer SSD PCB significantly enhances SSDs’ power efficiency by improving power distribution, reducing signal interference, managing thermal performance, and supporting high-speed data transfer with minimal energy consumption. The layered construction optimizes power usage, ensuring efficient energy use whether the SSD is active or idle. The 6-layer SSD PCB also supports advanced power management techniques, ensuring that the drive consumes the least power required for high-performance operations. As the demand for energy-efficient storage solutions grows, particularly in battery-powered devices, the 6-layer SSD PCB is crucial in developing SSDs that balance high performance with low energy consumption.