How can smart ring flex PCB be customized for different designs?

Bright rings are becoming increasingly popular in wearable technology, offering convenience and a seamless user experience for various applications, from fitness tracking to smart notifications. These devices integrate compact technology into a small form factor, and one of the key components enabling their functionality is the smart ring flex PCB. This circuit board supports efficient connectivity and power management in a small space, making it perfect for smart ring designs. In this article, we’ll explore how smart ring flex PCBs can be tailored for different designs, providing a guide for users and manufacturers looking to create their ideal smart ring.

Understanding the Basics of Flex PCBs in Smart Ring

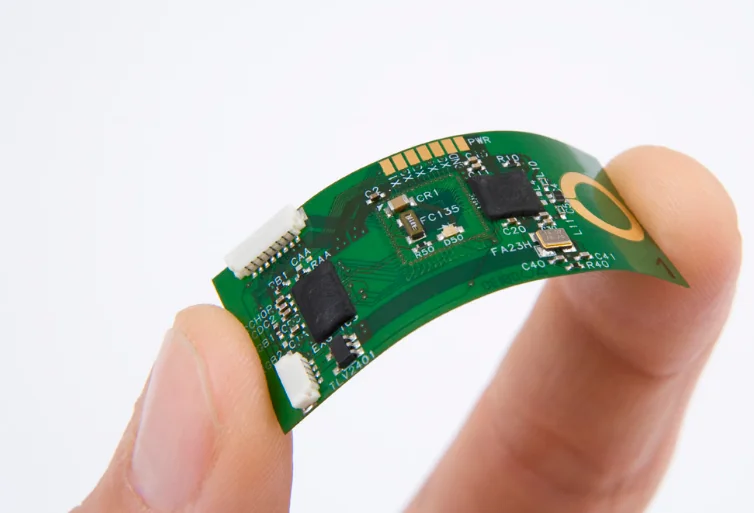

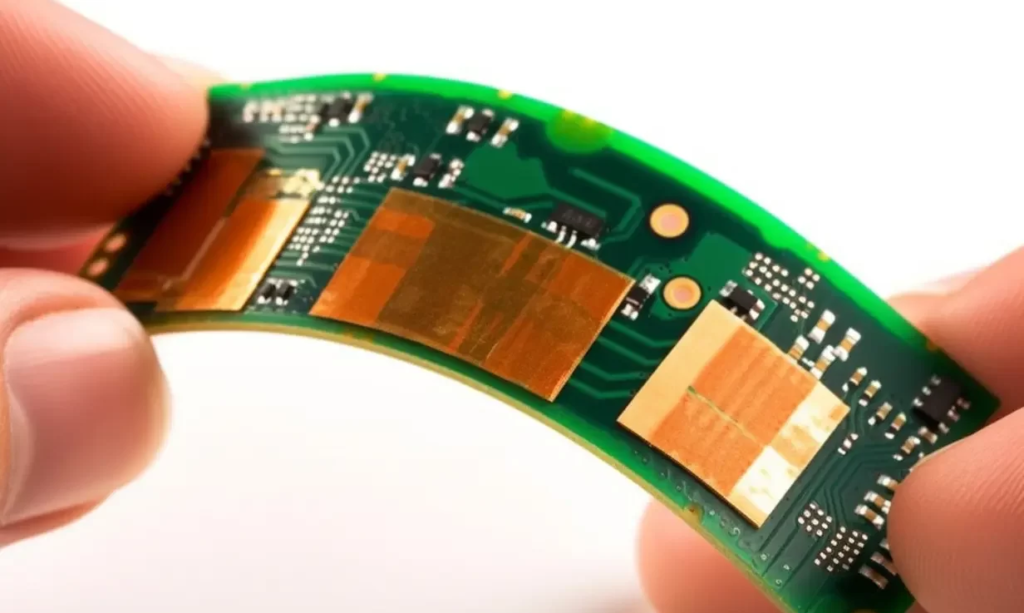

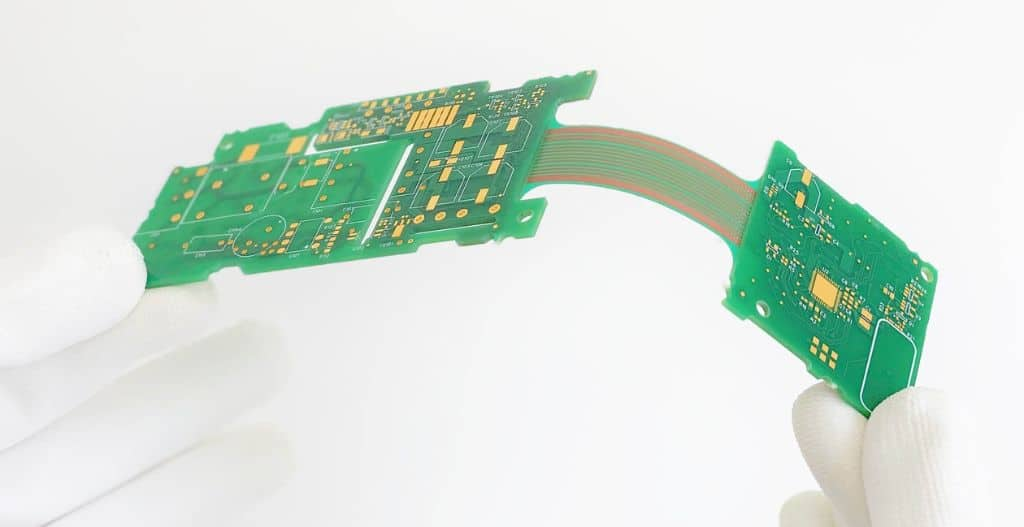

To appreciate customization options for smart ring flex PCBs, it’s essential to understand the role of flexible printed circuit boards in these devices. Flex PCBs bend and conform to different shapes, making them ideal for compact and curved devices like smart rings. Unlike traditional rigid PCBs, flex boards can wrap around surfaces and fit into confined spaces while maintaining high electrical performance.

In smart rings, flex PCBs connect components like sensors, processors, wireless modules, and power management circuits. These components must communicate effectively within the limited space, and the PCB’s flexibility allows for this seamless integration. Customizing the PCB layout ensures that each element is optimally placed for both performance and comfort.

Key Factors for Customizing Smart Ring Flex PCB

When customizing smart ring flex PCBs, several factors must be considered. The first is the size and form factor of the ring. The PCB must be compact enough to fit into the narrow, round design of the smart ring while still supporting all necessary components. Flexibility is essential, but the design must also be durable enough to withstand the constant flexing and movement inherent in wearable devices.

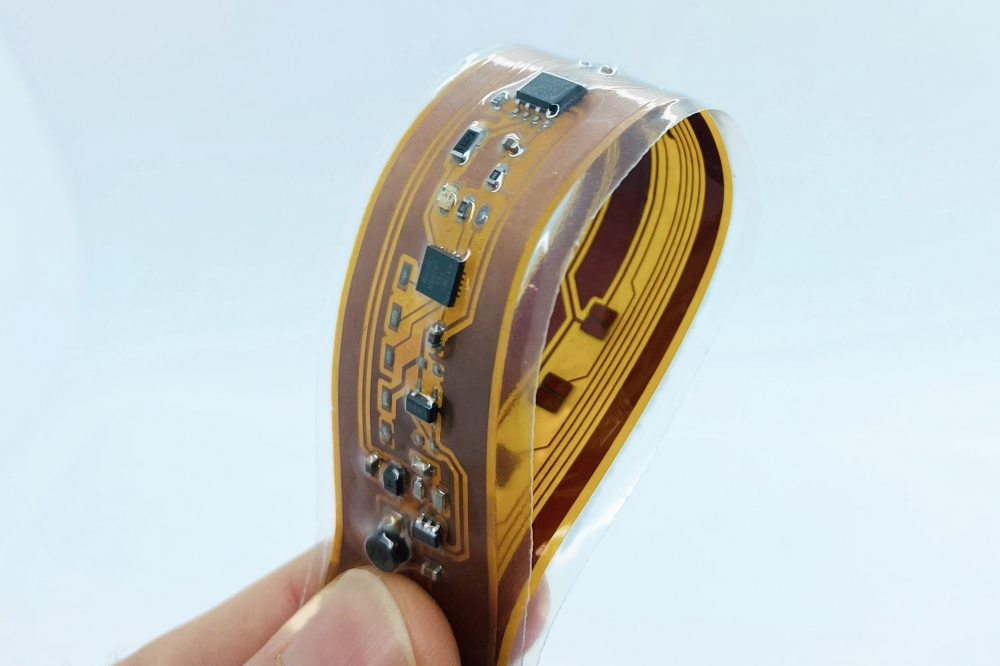

Another important consideration is the material used for the flex PCB. Flexible boards are often made from materials like polyimide or PET (polyethene terephthalate), which provide durability and flexibility. The material choice will depend on the specific application of the smart ring. For example, fitness or medical smart rings may require more durable materials to withstand sweat and wear over time.

Advanced Sensor Integration

A key customization in smart ring flex PCBs is the integration of sensors. Many smart rings include sensors for heart rate monitoring, motion detection, or temperature sensing. The placement of these sensors on the PCB is crucial for accuracy and performance.

Accelerometers and gyroscopes, for example, track movement and detect gestures. They are often embedded into the PCB using surface-mount technology (SMT). These sensors can be placed in various locations around the ring depending on the user’s needs. For health-focused smart rings, sensors need to be positioned for maximum skin contact to ensure accurate readings. On the other hand, smart rings designed for gesture control require sensors placed for optimal detection of hand movements.

Wireless Connectivity and Power Management

Wireless connectivity is another key feature of a smart ring flex PCB. Most smart rings use Bluetooth or NFC (Near Field Communication) to communicate with smartphones or other devices. The PCB must be customized to accommodate the correct wireless module and ensure efficient data transfer.

Power management is also critical. Since smart rings are small and wearable, battery life is a major concern. A customized PCB optimizes power consumption through efficient circuit design, possibly integrating a low-power Bluetooth chip or a custom power management IC (integrated circuit). Techniques like energy harvesting or wireless charging could be incorporated to extend battery life and improve user experience.

Customization for Aesthetic and Functional Design

Beyond the technical components, smart ring flex PCBs also need to be customized for aesthetic and ergonomic needs. Because smart rings are worn on the finger, they must be comfortable, lightweight, and visually appealing.

The PCB layout can be customized to reduce the size of the ring without sacrificing functionality. For instance, custom PCBs can be designed to avoid sharp edges, making the ring comfortable for daily wear. Additionally, the PCB can be shaped for ergonomic designs that fit the natural curve of the finger. The visual design can also be tailored to match the overall look of the ring, ensuring it blends seamlessly with jewellery aesthetics.

Challenges and Considerations in Customizing Smart Ring Flex PCBs

While there is great potential for customization in smart ring flex PCBs, designers must overcome several challenges. First, the issue of miniaturization must be addressed. Smart rings are inherently compact, and fitting all necessary components into such a small space requires advanced design techniques and cutting-edge manufacturing processes.

Customization must also consider the ring’s durability and longevity. Flex PCBs are more vulnerable to stress and wear than rigid boards, so material choice and design are crucial. Water resistance and protection from dirt, sweat, or other external elements are also important factors to consider.

The Future of Customization in Smart Ring Flex PCBs

The future of smart ring flex PCB customization lies in advancing technologies that enhance performance, flexibility, and functionality. As new sensors and connectivity technologies emerge, smart rings will continue to evolve, and more sophisticated customizations will be needed in their PCBs.

New, smaller sensors for biometric tracking could lead to even more compact designs, resulting in lighter and more comfortable rings. Additionally, advancements in wireless power transfer or solar charging could reduce the need for frequent charging, enhancing user convenience.

As technology advances, smart ring flex PCBs will become more powerful, offering a broader range of customization options across industries like healthcare and fashion.

The Importance of Customization for Smart Ring Flex PCB

Smart ring flex PCBs are crucial to the performance, functionality, and design of smart rings. Customizing these PCBs allows manufacturers to optimize performance while meeting the specific requirements of end users. Whether it’s integrating sensors, optimizing power management, or designing for aesthetic appeal, the customization possibilities for smart ring flex PCBs are vast.