2-Layer SSD PCB vs. Multi-Layer PCBs: Which is Best for Your Storage Needs?

In solid-state drives (SSDs), the design and construction of the printed circuit board (PCB) play a critical role in determining performance, reliability, and cost. One of the key decisions manufacturers and consumers face is choosing between a 2-layer SSD PCB and a multi-layer PCB. Each option has advantages and trade-offs, making the choice highly dependent on specific storage needs and use cases. This blog post will explore the differences between these two types of PCBs, their impact on SSD performance, and how to determine which one is best suited for your requirements.

Differences between 2-layer SSD PCB and Multi-layer PCB

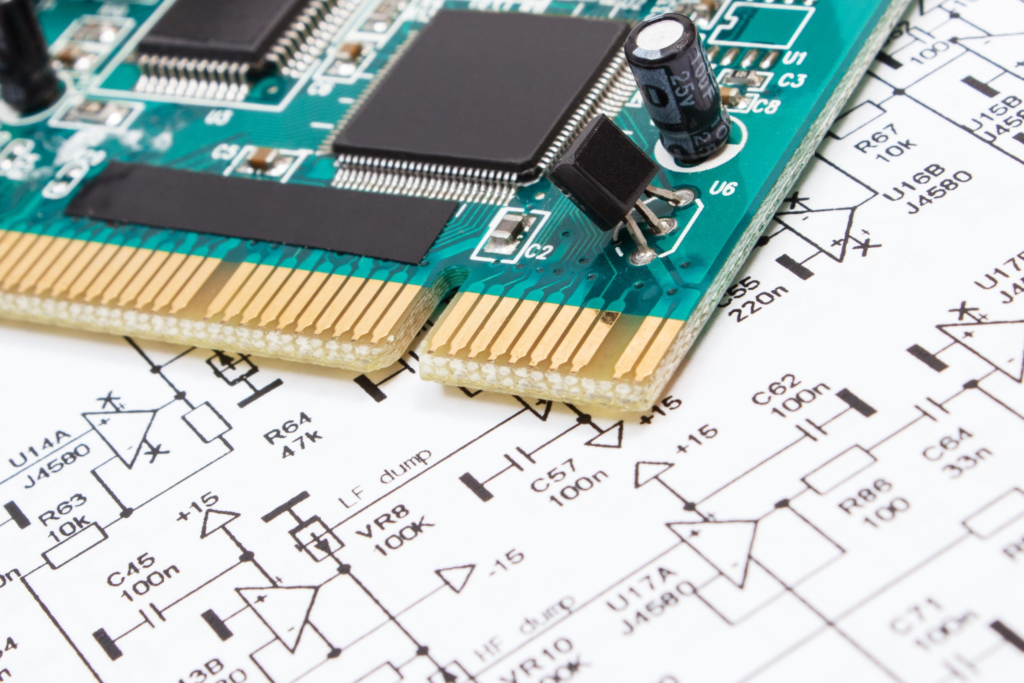

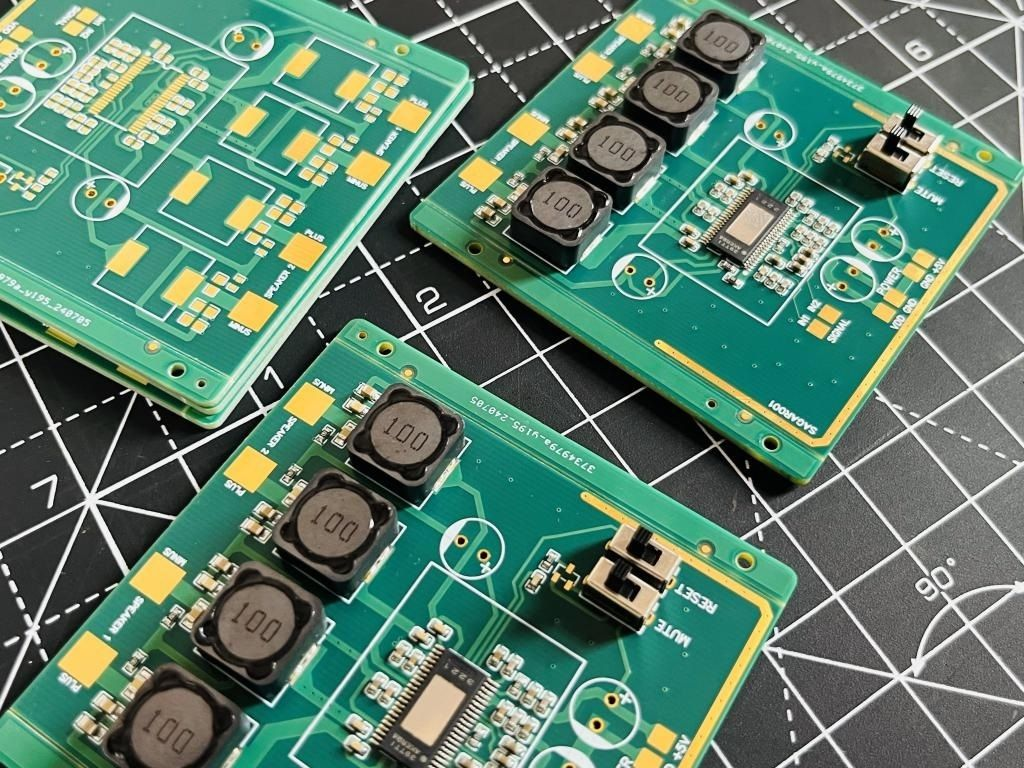

Before diving into the specifics of 2-layer SSD PCBs and multi-layer PCBs, it’s essential to understand the fundamentals of PCB design. A PCB serves as the backbone of an SSD, connecting all its components, such as memory chips, controllers, and connectors. The number of layers in a PCB refers to the number of conductive copper layers sandwiched between insulating material. A 2-layer SSD PCB has two layers, while multi-layer PCBs can have four, six, or even more layers. The choice of layers affects signal integrity, power distribution, and thermal management, which are crucial for SSD performance.

The Advantages of a 2-Layer SSD PCB

A 2-layer SSD PCB is often the go-to choice for budget-friendly and less complex SSDs. Its simplicity makes manufacturing more straightforward and cheaper, lowering consumer costs. This type of PCB is ideal for entry-level or mid-range SSDs, where high-speed performance and advanced features are not the primary focus. Additionally, the straightforward design of a 2-layer SSD PCB makes it easier to troubleshoot and repair, which can be a significant advantage for DIY enthusiasts and small-scale manufacturers. However, its signal routing and power delivery limitations may not meet the demands of high-performance SSDs.

When Multi-Layer PCB Shine

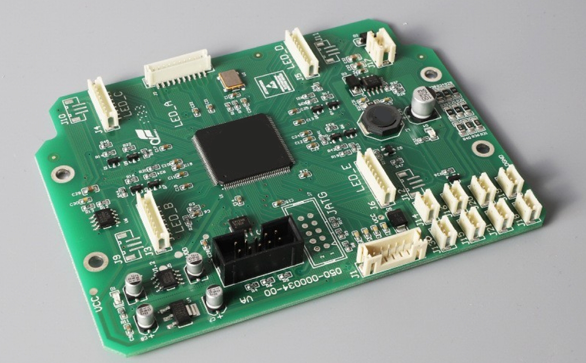

Multi-layer PCBs, on the other hand, are designed to handle more complex and high-performance SSDs. With additional layers, these PCBs offer better signal integrity, reduced electromagnetic interference (EMI), and improved power distribution. This makes them ideal for high-speed SSDs used in gaming, data centers, or enterprise applications. The extra layers also allow for more compact designs, enabling manufacturers to pack more features into smaller form factors. While multi-layer PCBs have higher manufacturing costs, their superior performance and reliability often justify the investment for demanding use cases.

Performance Considerations for SSDs

Performance is critical when choosing between 2-layer SSD PCBs and a multi-layer PCB. A 2-layer SSD PCB may suffice for basic tasks like web browsing, document editing, or light gaming. However, multi-layer PCBs are better for tasks requiring high-speed data transfer, such as video editing, 3D rendering, or running virtual machines. The enhanced signal integrity and reduced latency of multi-layer PCBs ensure that the SSD can handle intensive workloads without compromising performance. This makes them a preferred choice for professionals and power users.

Cost and Manufacturing Complexity

Cost is often a deciding factor when choosing between 2-layer SSD PCBs and a multi-layer PCB. The more straightforward design of 2-layer SSD PCBs results in lower material and manufacturing costs, making it an attractive option for budget-conscious consumers. On the other hand, multi-layer PCBs require advanced manufacturing techniques and higher-quality materials, which drive up costs. However, the increased cost is often offset by the improved performance and durability of multi-layer PCBs. Multi-layer PCBs are usually the better investment for businesses and individuals prioritizing long-term value over upfront savings.

Thermal Management and Durability

Thermal management is another crucial aspect when comparing 2-layer SSDs and multi-layer PCBs. Due to their additional layers and advanced design, multi-layer PCBs typically have better heat dissipation capabilities. This is particularly important for high-performance SSDs, which generate more heat during operation. A 2-layer SSD PCB, while simpler, may struggle to manage heat effectively in demanding scenarios, potentially leading to reduced lifespan and reliability. Multi-layer PCBs are the clear winner for applications where durability and consistent performance are paramount.

Choosing the Right PCB for Your Needs

The choice between a 2-layer SSD PCB and a multi-layer PCB ultimately depends on your specific storage needs and budget. If you’re looking for an affordable SSD for everyday tasks, a 2-layer SSD PCB may be sufficient. However, multi-layer PCBs are the way to go if you require high-speed performance, advanced features, and long-term reliability. Consider factors like your workload, performance expectations, and budget when deciding. Consulting with a trusted manufacturer or supplier can also help you make an informed choice.

Making the Right Choice Between 2-Layer SSD PCB and Multi-Layer PCBs

There is no one-size-fits-all answer in the debate between 2-layer SSDs and multi-layer PCBs. Each option has strengths and weaknesses, making them suitable for different use cases. 2-layer SSD PCBs offer simplicity and affordability, making them ideal for essential storage. Multi-layer PCBs, on the other hand, provide superior performance, durability, and thermal management, making them the preferred choice for high-performance applications. By understanding the differences and evaluating your requirements, you can choose the PCB that best meets your storage needs and ensures optimal performance for years.