User Guide: Maintaining and Caring for Devices with Gold Finger PCB

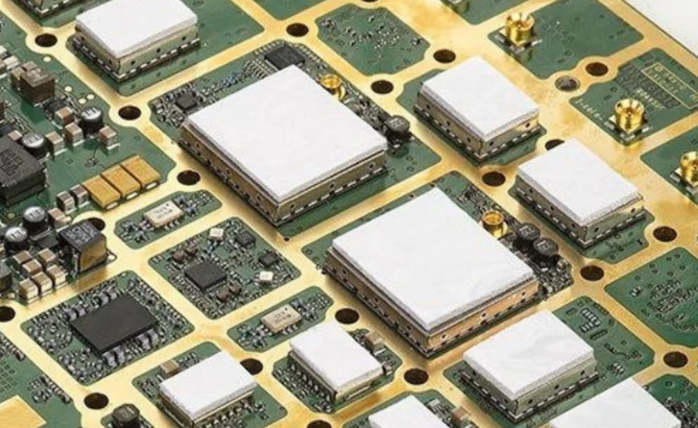

Gold Finger PCBs are vital for high-performance electronics, providing reliable connectivity in devices like graphics cards, RAM, and industrial equipment. The gold-plated edges offer excellent conductivity, corrosion resistance, and durability. However, dust, moisture, and wear can affect their performance. Proper care and maintenance are key to extending the lifespan of your devices and avoiding costly repairs. This guide will show you how to protect and preserve Gold Finger PCB for long-term reliability.

Why Gold Finger PCB Require Special Care

The Gold Finger PCB is more durable than standard connectors but needs proper maintenance. The thin gold plating can wear off if exposed to frequent insertion cycles or abrasive cleaning methods. Contaminants like dust, oils, and moisture can also reduce conductivity over time. Without care, signal degradation and connection failures may occur.

Moreover, gold is a soft metal, making it susceptible to scratches. Rough handling during installation or cleaning can damage the plating. Unlike cheaper tin or nickel connectors, Gold Finger PCBs demand gentler treatment. By understanding their vulnerabilities, you can take proactive steps to preserve their performance. Proper care ensures stable connections and prevents intermittent faults in critical devices.

Cleaning Gold Finger PCB: Best Practices

Regular cleaning keeps Gold Finger PCBs in top condition. Always use a soft, lint-free cloth or an electronics-grade cleaning swab. Isopropyl alcohol (90% or higher) works best for removing dirt and oxidation. Avoid abrasive materials like paper towels, which can scratch the gold plating.

Additionally, never apply excessive pressure while cleaning. Gently wipe along the fingers in one direction to prevent debris from embedding into the contacts. For stubborn grime, use a specialized contact cleaner. After cleaning, let the PCB dry completely before reinserting it. Proper cleaning prevents signal loss and maintains optimal electrical performance.

Handling and Installation Tips for Longevity

Proper handling minimizes wear on Gold Finger PCBs. Always hold the PCB by its edges to avoid touching the gold contacts. Skin oils can cause corrosion over time. When inserting or removing the PCB, align it carefully to prevent bending or misalignment. Forcing a connector can damage both the PCB and the slot.

Furthermore, limit unnecessary insertions and removals. Each cycle wears down the gold plating slightly. If testing is required, use an extender or test socket. Consider using connector guides for industrial applications to ensure smooth, damage-free installations. These small precautions significantly extend the lifespan of Gold Finger PCBs.

Protecting PCBs from Environmental Damage

Environmental factors like humidity, dust, and temperature fluctuations can harm Gold Finger PCBs—store devices in a dry, climate-controlled environment to prevent moisture buildup. Silica gel packets in storage containers help absorb excess humidity.

Additionally, avoid exposing PCBs to corrosive chemicals or airborne contaminants. In industrial settings, protective enclosures or conformal coatings can shield gold fingers from harsh conditions. Regular inspections for signs of oxidation or contamination ensure early detection of potential issues. Proactive protection maintains reliability in demanding applications.

Troubleshooting Common PCB Connectivity Issues

Even with proper care, issues may arise. If a device fails to connect, inspect the gold fingers for discolouration or scratches. Oxidation appears as dark spots, while wear shows as uneven plating. A gentle cleaning with isopropyl alcohol often resolves minor connectivity problems.

For persistent issues, check the connector slot for debris or bent pins. Sometimes, the problem lies in the mating connector rather than the PCB itself. If the gold plating is severely worn, professional re-plating may be necessary. Early troubleshooting prevents further damage and costly replacements.

When to Replace Gold Finger PCBs

Despite best efforts, Gold Finger PCB eventually wear out. Frequent connection failures, visible plating wear, or corrosion are signs of degradation. If cleaning and reseating don’t restore functionality, replacement may be the only option.

High-performance systems like servers or medical equipment should use high-quality, gold-plated replacements. Cheap alternatives with inferior plating can lead to premature failure. Investing in durable, well-manufactured PCBs ensures long-term reliability. Always source replacements from reputable suppliers.

Maximizing the Lifespan of Gold Finger PCBs

Gold Finger PCBs are vital for high-performance electronics but require careful maintenance. Proper cleaning, handling, and environmental protection keep them functioning optimally. Regular inspections and prompt troubleshooting prevent minor issues from becoming significant failures. By following this guide, you can extend the life of your Gold Finger PCBs and maintain peak device performance. Proactive care ensures reliable connectivity for personal gadgets or industrial systems. Protect your investment by adopting these best practices today.