Why Ceramic PCB Is Becoming Popular in RF and Microwave Applications

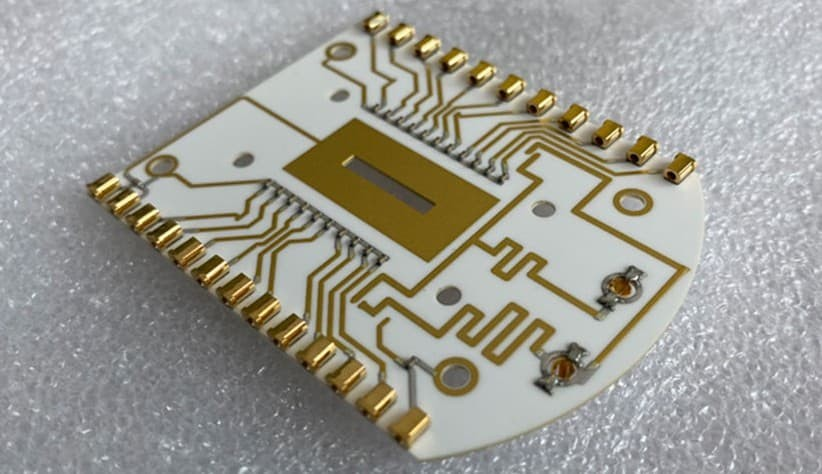

Due to their excellent performance characteristics, ceramic PCBs have become a significant choice for RF and microwave applications. While traditional PCB materials like FR4 have served well in many applications, RF and microwave systems require materials that can handle higher frequencies and temperatures. Ceramic PCB is emerging as the ideal solution. They offer unique benefits, including enhanced thermal management, reduced signal loss, and improved reliability. In this blog, we will explore why Ceramic PCBs are gaining popularity in RF and microwave technology and their advantages over conventional materials.

A Key Factor in Ceramic PCB Success

Effective thermal management is essential for high-performance RF and microwave systems. These systems often generate a significant amount of heat, which can cause components to fail if not properly dissipated. Ceramic PCBs stand out because of their superior thermal conductivity compared to other materials. They can absorb and disperse heat more efficiently, ensuring that components maintain optimal temperature levels. This ability to handle heat is crucial for preventing performance degradation and extending the lifespan of sensitive components.

The high thermal conductivity of Ceramic PCBs, particularly those made from aluminum nitride or alumina, ensures that RF components stay cool, even in challenging environments. This makes Ceramic PCBs especially suitable for high-power applications, such as satellite communication and radar systems, where heat dissipation is critical. Moreover, these PCBs help enhance the reliability and overall performance of RF and microwave systems by keeping temperatures under control.

Optimizing Signal Integrity for High-Frequency Applications

One of the most critical requirements in RF and microwave applications is handling high-frequency signals without significant losses. Due to their higher dielectric losses, traditional PCB materials like FR4 struggle to perform well at higher frequencies. Ceramic PCBs, on the other hand, offer much lower dielectric loss, making them ideal for high-frequency applications. This reduced signal attenuation means the signal integrity remains high, even at high frequencies.

Ceramic materials are engineered to offer low loss factors and consistent performance across a wide frequency range, making them perfect for advanced communication systems. This is particularly crucial in applications like 5G networks, where data transmission speeds are incredibly high. Engineers can use Ceramic PCBs to ensure that their designs perform reliably without worrying about signal degradation. This superior high-frequency performance is one of the main reasons Ceramic PCBs are becoming increasingly popular in RF and microwave applications.

Stability and Reliability in Harsh Environments

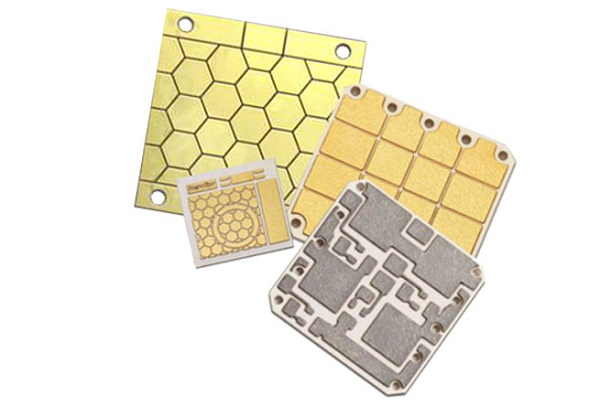

RF and microwave systems are often used in extreme conditions, where temperature fluctuations and mechanical stresses can impact performance. Ceramic PCBs are highly stable and maintain mechanical and electrical properties even in challenging environments. They can withstand high temperatures and mechanical stresses without degrading, making them more reliable than other materials. This makes them ideal for aerospace, defense, and telecommunications applications, where failure is not an option.

The stability of Ceramic PCBs in harsh environments also makes them ideal for military-grade equipment and space applications. These systems require materials that can handle extreme temperatures, vibrations, and other harsh conditions without failing. Ceramic PCBs ensure that critical components in RF and microwave systems operate reliably, even in these harsh conditions. As a result, the adoption of Ceramic PCBs is rapidly increasing in sectors where performance and reliability are paramount.

Miniaturization Capabilities in Modern Electronics

As electronic devices become smaller and more compact, there is a growing need for materials that can support miniaturization without compromising performance. Ceramic PCBs are perfect for this task because they support high-density designs. These PCBs can accommodate more components in a smaller space, which is essential for miniaturizing RF and microwave systems.

Integrating more components into a smaller area without sacrificing performance is crucial in developing advanced communication devices and wearable electronics. Ceramic PCBs enable engineers to design smaller, more efficient systems while ensuring high performance. This miniaturization capability is one reason why Ceramic PCBs are becoming increasingly popular in RF and microwave applications, especially in modern consumer electronics.

Mechanical Strength and Durability of Ceramic PCB

Ceramic PCBs offer exceptional mechanical strength, making them more durable than other PCB materials. This is particularly important in RF and microwave applications, where components are often subjected to mechanical stresses, vibrations, and thermal cycling. Ceramic PCBs can withstand these stresses better than traditional materials like FR4, which may crack or warp under harsh conditions.

The durability of Ceramic PCBs ensures that they continue to perform reliably over long periods, even in the most demanding environments. This makes them ideal for long-term applications, such as military or aerospace systems, where durability and longevity are critical. With Ceramic PCBs, engineers can be confident that their designs will remain intact and functional, even under challenging mechanical stresses.

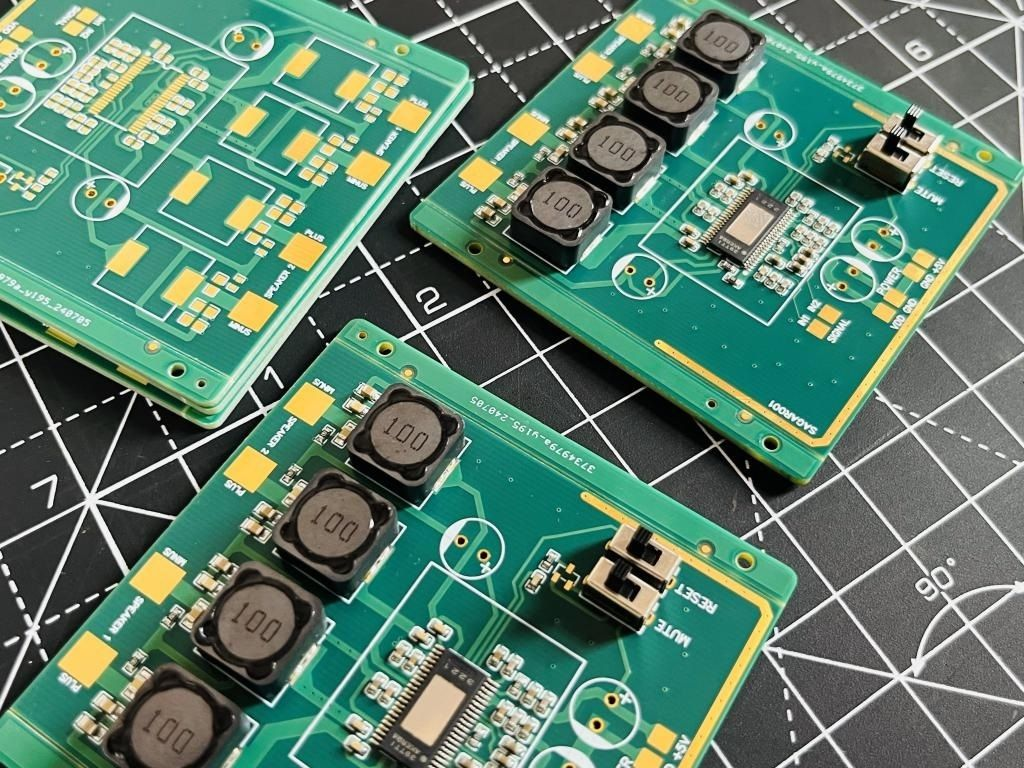

Cost-Effective Manufacturing and Accessibility

Despite their high performance, Ceramic PCBs have become more cost-effective recently. Advances in manufacturing processes have made it possible to produce Ceramic PCBs at scale, reducing costs and making them more accessible for a wide range of applications. As demand for Ceramic PCBs grows, manufacturers find more efficient ways to produce these components, further driving down prices.

This cost-effectiveness makes Ceramic PCBs an attractive option for industries balancing performance with budget constraints. While Ceramic PCBs may still be more expensive than traditional materials, their long-term performance and reliability often make them a more cost-effective choice in the long run. This combination of high performance and affordability is one of the key reasons ceramic PCB is becoming increasingly popular in RF and microwave applications.

Ceramic PCB in the Age of 5G and IoT

The rise of 5G technology and the Internet of Things (IoT) has created a massive demand for high-performance, high-frequency components. Ceramic PCBs are ideally suited for these applications, as they offer low loss and high-frequency performance for 5G networks and IoT devices. These systems require materials that can handle high-frequency signals with minimal signal loss and efficient thermal management, both of which are strengths of Ceramic PCBs.

As the rollout of 5G continues and IoT devices become more ubiquitous, the demand for Ceramic PCBs is expected to increase. These technologies rely on fast, reliable data transmission, and Ceramic PCBs are essential in ensuring that these systems function efficiently. As a result, Ceramic PCBs are positioned to play a key role in the next generation of communication technologies.

The Future of Ceramic PCB in RF and Microwave Applications

Ceramic PCBs have proven invaluable in RF and microwave applications due to their superior thermal management, high-frequency performance, mechanical strength, and reliability. These qualities make Ceramic PCBs the material of choice for advanced communication systems, military applications, and space technology. As the demand for more efficient, compact, and reliable systems grows, Ceramic PCBs will continue to play a vital role in shaping the future of RF and microwave technology. With their unique combination of performance, durability, and cost-effectiveness, Ceramic PCBs are set to remain a key component in the evolution of high-performance electronics.