Application of 2 layer PCB in modern electronic products

PCBs are the backbone of modern electronics, and the 2-layer PCB is one of the most widely used types. Its simplicity, cost-effectiveness, and versatility make it a popular choice for various electronic devices. The 2-layer PCB is critical in ensuring functionality and reliability, from consumer gadgets to industrial equipment. This blog post will explore its applications, benefits, and why it remains a cornerstone in the electronics industry.

2-layer PCB is the foundation of electronic design

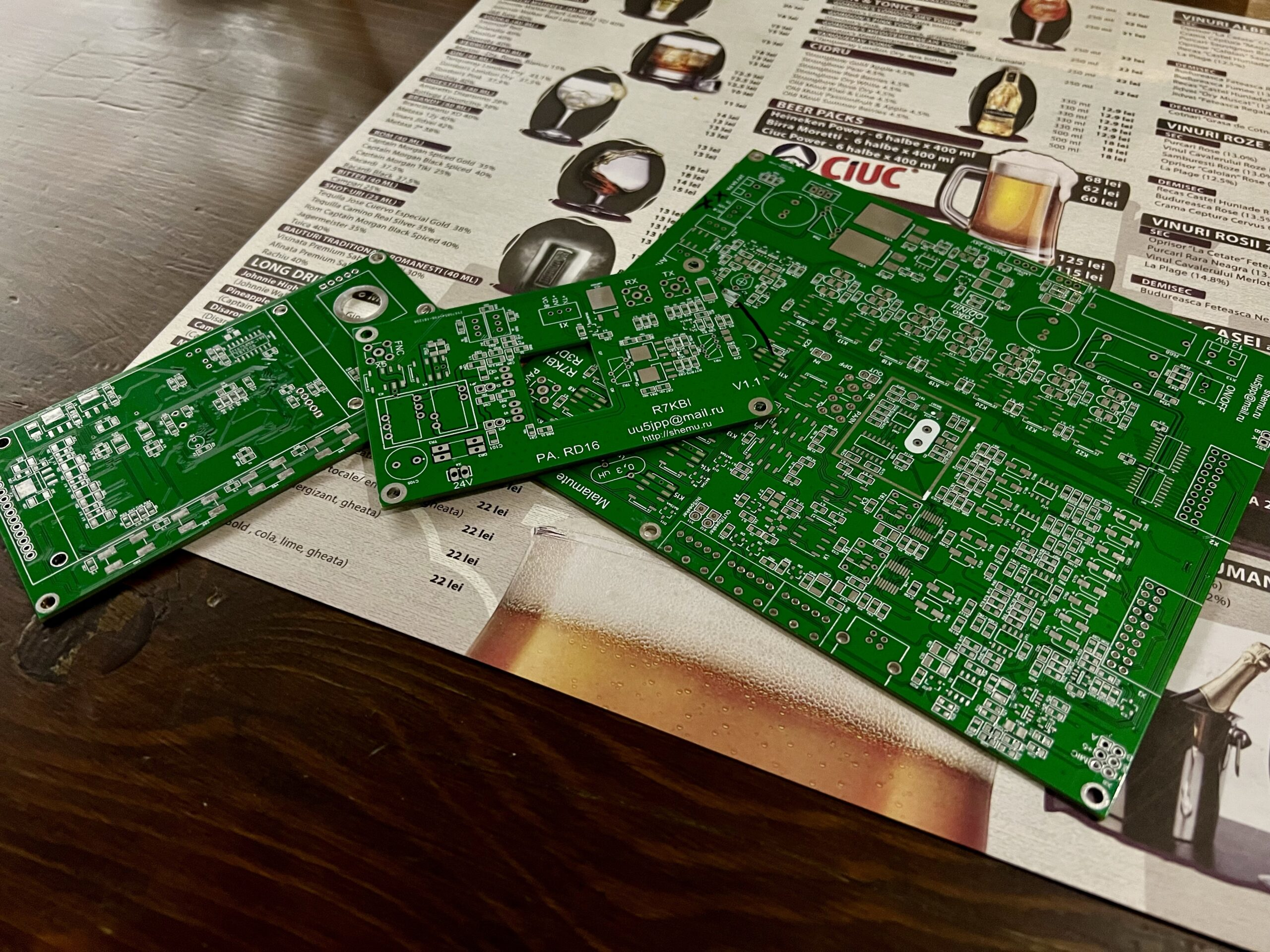

The 2-layer PCB consists of two conductive layers of copper, one on the top and one on the bottom, separated by an insulating substrate. This design balances simplicity and functionality, making it ideal for many applications. Engineers often choose this type of PCB for its ease of manufacturing and lower cost than multi-layer alternatives. For instance, a study by Grand View Research found that the global PCB market, including 2-layer PCBs, is projected to reach $89.7 billion by 2028, driven by demand for cost-effective solutions.

In modern electronics, the 2-layer PCB is the foundation for countless devices. For example, it powers everyday gadgets like remote controls, LED lighting systems, and power supplies. Its ability to handle moderate circuit complexity while maintaining affordability makes it a go-to solution for startups and established manufacturers. The design flexibility of the 2-layer PCB also allows for efficient routing of electrical signals, ensuring optimal performance without the need for additional layers.

Powering Consumer Electronics

Consumer electronics rely heavily on the 2-layer PCB due to its compact design and cost efficiency. Smartphones, tablets, and wearable technology often use these boards for specific components. For instance, the charging circuits in smartphones frequently utilize 2-layer PCBs to manage power distribution effectively; according to a report by Statista, the global consumer electronics market is expected to grow to $1.5 trillion by 2027, with 2-layer PCBs playing a key role in this expansion.

Another example is home appliances like microwaves and washing machines. These devices require reliable circuitry, and the 2-layer PCB provides the necessary performance without driving up production costs. Its ability to handle analog and digital signals makes it versatile for various applications—moreover, the gaming industry benefits from this technology. Gaming consoles and accessories often incorporate 2 layer PCBs for their controllers and power modules, ensuring a seamless user experience while keeping manufacturing expenses low.

Enabling Industrial Automation

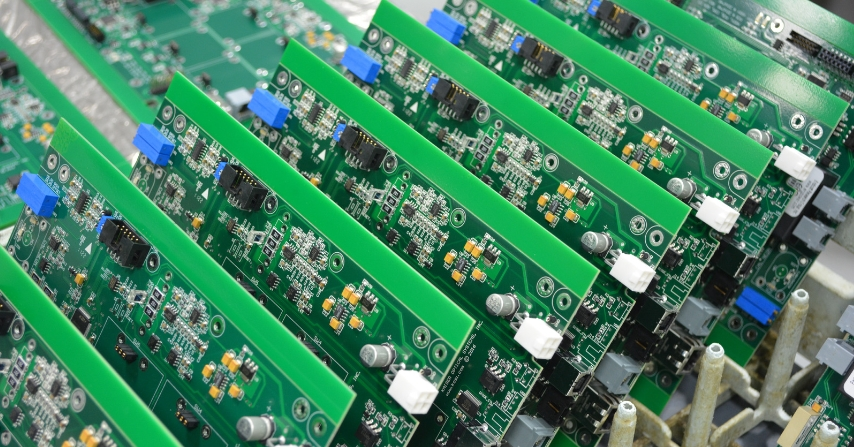

The 2-layer PCB plays a vital role in automation and control systems in the industrial sector. Machines used in manufacturing, such as conveyor belts and robotic arms, depend on these boards for efficient operation. The 2-layer PCB provides the necessary circuitry to control motors, sensors, and other critical components. A case study by Siemens revealed that factories using 2-layer PCBs in their automation systems saw a 20% increase in production efficiency.

One notable application is in Programmable Logic Controllers (PLCs). These devices use 2-layer PCBs to process input signals and execute commands, ensuring smooth automation processes. The durability of these boards also makes them suitable for harsh industrial environments—additionally, the energy sector benefits from this technology. Solar inverters and wind turbine controllers often use 2-layer PCBs to manage power conversion and distribution, highlighting their importance in advancing sustainable energy solutions.

2-layer PCB Driving Automotive Innovations

The automotive industry has embraced the 2-layer PCB for its reliability and cost-effectiveness. Modern vehicles incorporate numerous electronic systems, from infotainment to engine control units (ECUs). These systems rely on 2-layer PCBs to function efficiently. For example, dashboard displays and GPS navigation systems use these boards to process and display information. A report by Deloitte estimates that electronics account for 40% of a car’s total cost, with 2-layer PCBs being a significant contributor.

Electric vehicles (EVs) also benefit from this technology. Charging stations and battery management systems often use 2-layer PCBs to monitor and control power flow. This underscores their role in the transition to greener transportation. For instance, Tesla’s battery management systems incorporate 2-layer PCBs to ensure optimal performance and safety, showcasing their importance in cutting-edge automotive technology.

Supporting Medical Devices

The medical industry demands high reliability and precision, and the 2-layer PCB meets these requirements effectively. Medical devices such as blood glucose monitors, heart rate sensors, and imaging equipment rely on these boards for accurate performance. For instance, portable medical devices often use 2-layer PCBs due to their compact size and lightweight design. A study by MarketsandMarkets predicts the medical electronics market will reach $6.8 billion by 2026, with 2-layer PCBs being a key enabler.

Moreover, diagnostic equipment like ultrasound machines and X-ray systems incorporate 2-layer PCBs to process complex signals. Their ability to handle high-frequency signals ensures accurate diagnostics, improving patient outcomes. For example, GE Healthcare uses 2-layer PCBs in its imaging systems to deliver high-quality results, demonstrating their critical role in modern healthcare.

Enhancing IoT Devices

The Internet of Things (IoT) has revolutionized how we interact with technology, and the 2-layer PCB is at the heart of this transformation. IoT devices like smart thermostats, security cameras, and wearable fitness trackers rely on these boards for connectivity and functionality. For example, smart home devices use 2-layer PCBs to connect to Wi-Fi networks and process user commands. According to IoT Analytics, the number of connected IoT devices is expected to reach 27 billion by 2025, with 2-layer PCBs playing a crucial role in this growth.

Wearable technology, such as fitness bands and smartwatches, also benefits from this technology. The 2-layer PCB ensures these devices remain lightweight and energy-efficient, enhancing user comfort and convenience. For instance, Fitbit uses 2-layer PCBs in its fitness trackers to deliver reliable performance while maintaining a sleek design.

Advancing Aerospace Technology

The aerospace industry requires components that can withstand extreme conditions, and the 2-layer PCB delivers on this front. Aircraft systems, such as navigation and communication equipment, rely on these boards for reliable performance. For instance, flight control systems use 2-layer PCBs to process data from sensors and actuators. A report by Boeing highlights that modern aircraft contain over 10,000 PCBs, with 2-layer PCBs being a significant portion.

Satellites and space exploration equipment also incorporate 2-layer PCBs. Their ability to handle high-frequency signals and resist radiation makes them ideal for these demanding applications. For example, NASA’s Mars rovers use 2-layer PCBs in their communication systems, showcasing their reliability in extreme environments.

The Enduring Relevance of 2-Layer PCB

2-layer PCBs remain a cornerstone of modern electronics due to their versatility, cost-effectiveness, and reliability. The technology powers various applications, from consumer electronics to industrial machinery. Its ability to balance performance and price ensures its continued relevance in an ever-evolving industry. Whether designing a new product or optimizing an existing one, the technology offers practical and effective solutions. By understanding the many applications of 2-layer PCBs, you can make an informed decision regarding their use in your projects. Its enduring relevance highlights its importance in shaping the future of electronics.