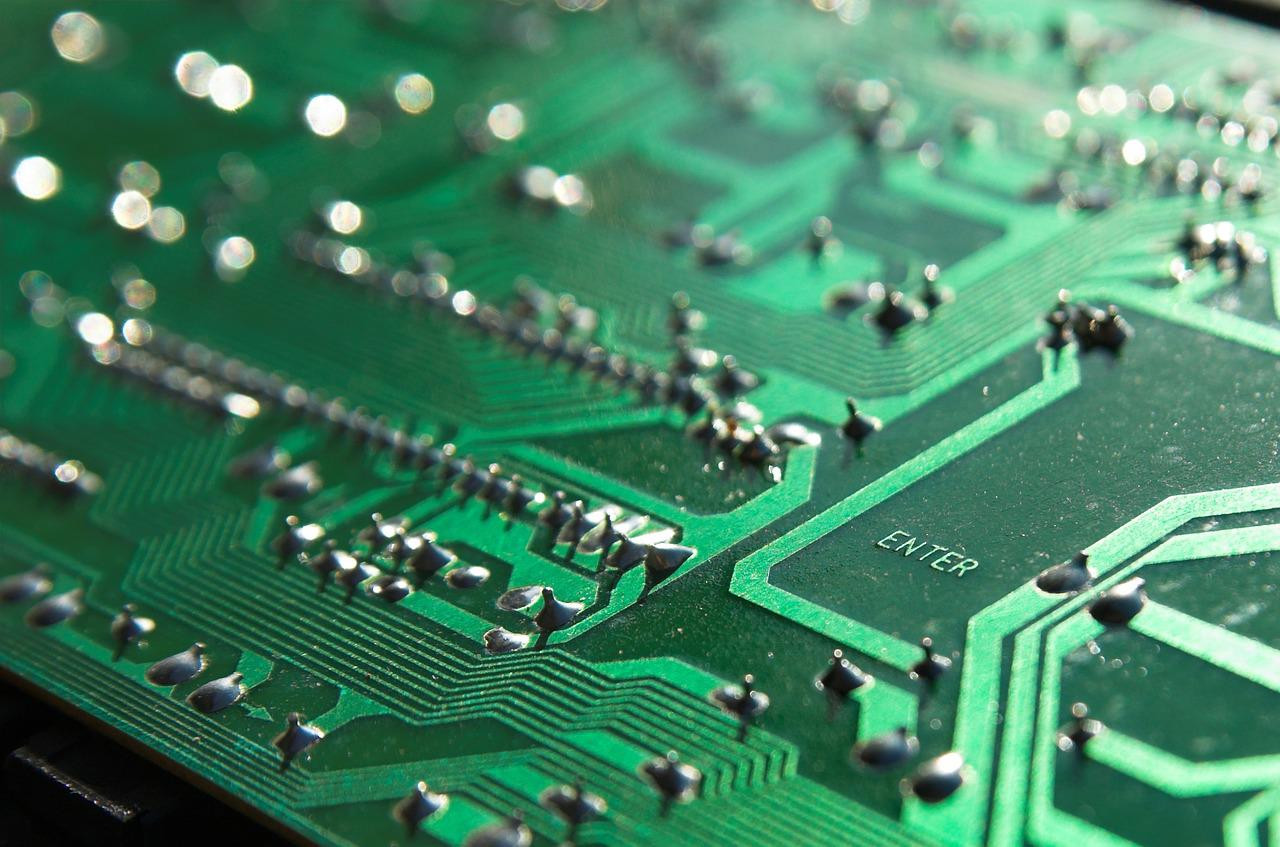

Designing Heavy Copper PCB demands precision beyond standard boards – optimizing thermal performance, current capacity, and structural integrity from the outset. While traditional PCB tools struggle with high-power requirements, modern interactive design platforms like Altium Designer and Cadence Allegro empower engineers to simulate thermal behaviour, adjust trace geometries, and validate current loads in real time. […]

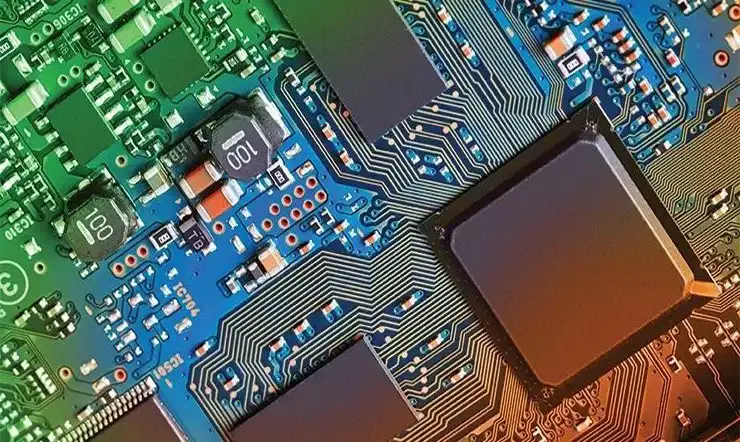

In high-speed circuit design, electromagnetic interference (EMI) and crosstalk pose critical challenges that demand strategic PCB solutions. Double-sided PCBs provide engineers with essential tools to address these issues, offering dual-layer component placement and routing flexibility that significantly enhances signal integrity. By effectively separating analog and digital circuits across layers, these boards reduce noise coupling while […]

Over the past two decades, SSD PCB architecture has transformed storage technology. Starting with SATA-based designs that mimicked HDD limitations, it rapidly advanced to PCIe and NVMe interfaces that unlocked unprecedented speed and efficiency. This evolution didn’t just boost performance; it redefined how systems access data, powering everything from consumer laptops to enterprise servers. Today’s […]

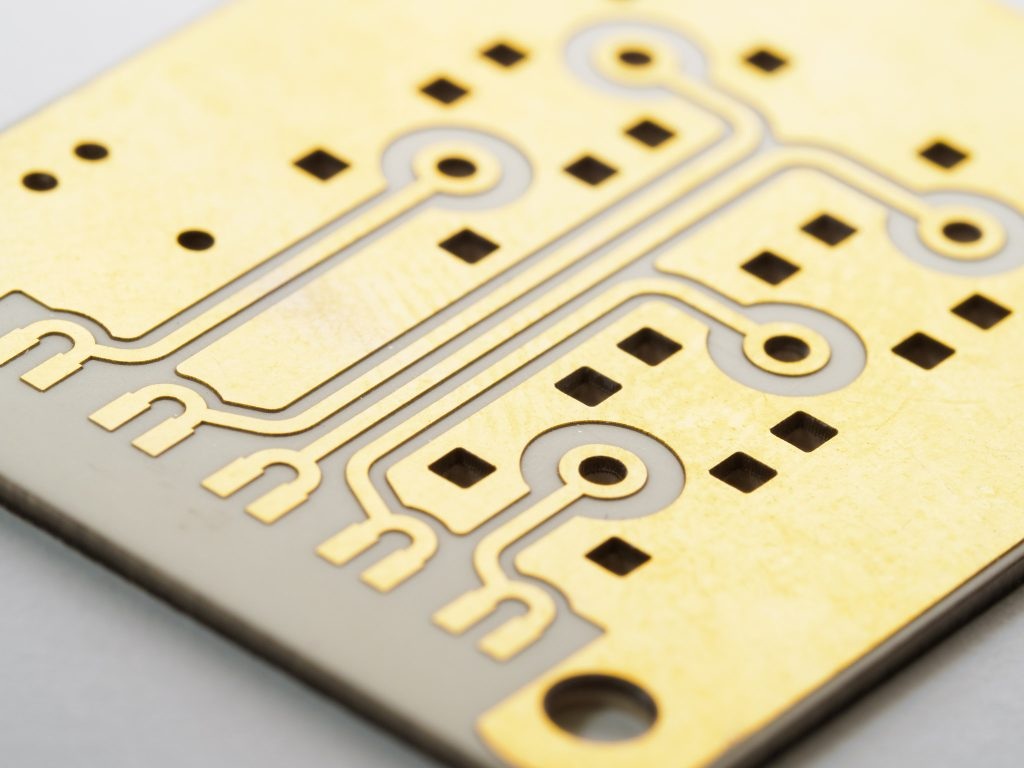

Maintaining signal integrity is paramount for successful system performance in modern RF design. The Ceramic PCB has emerged as the substrate for high-frequency applications due to its exceptional dielectric properties and thermal characteristics. Unlike conventional FR-4 boards that struggle above a few GHz, ceramic substrates like alumina and aluminum nitride maintain stable electrical performance well […]

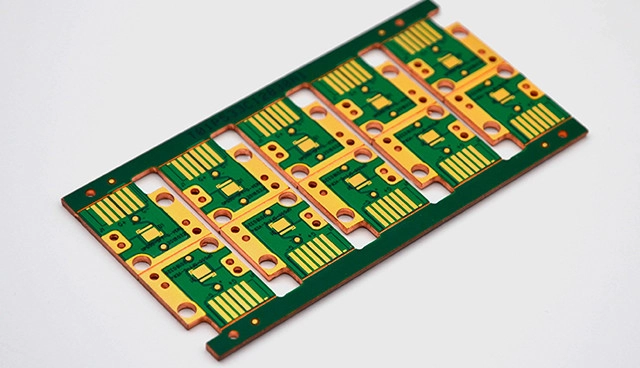

Gold Finger PCBs are vital for high-performance electronics, providing reliable connectivity in devices like graphics cards, RAM, and industrial equipment. The gold-plated edges offer excellent conductivity, corrosion resistance, and durability. However, dust, moisture, and wear can affect their performance. Proper care and maintenance are key to extending the lifespan of your devices and avoiding costly […]

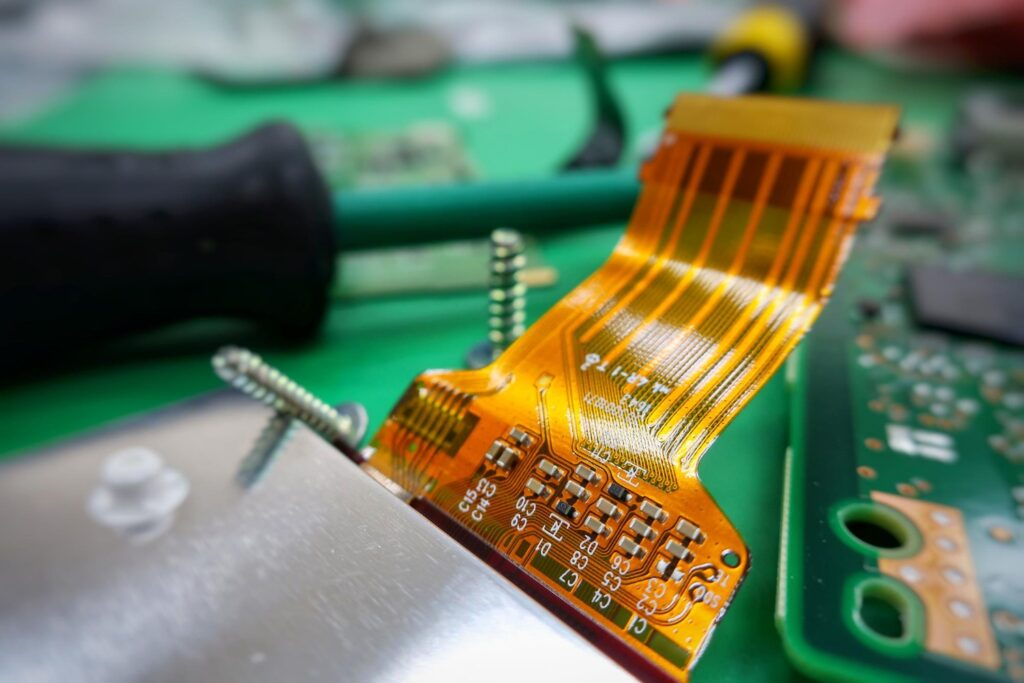

In industrial environments, durability and reliability are non-negotiable. Traditional PCBs often fall short under constant motion and stress. Rigid-Flex PCB technology combines rigid strength with flexible adaptability, offering a more innovative, resilient solution. Ideal for control systems, robotic arms, and high-vibration machinery, Rigid-Flex PCBs ensure performance where it matters most. In this blog post, we’ll […]

Carbon-ink PCB technology represents a cost-effective solution for various electronic applications. These printed circuit boards utilize conductive carbon-based inks instead of traditional copper traces, offering unique advantages in specific use cases. Due to their simplicity and reliability, carbon-ink PCB designs have gained popularity in consumer electronics, automotive controls, and medical devices. Carbon Ink PCB’s manufacturing process differs […]

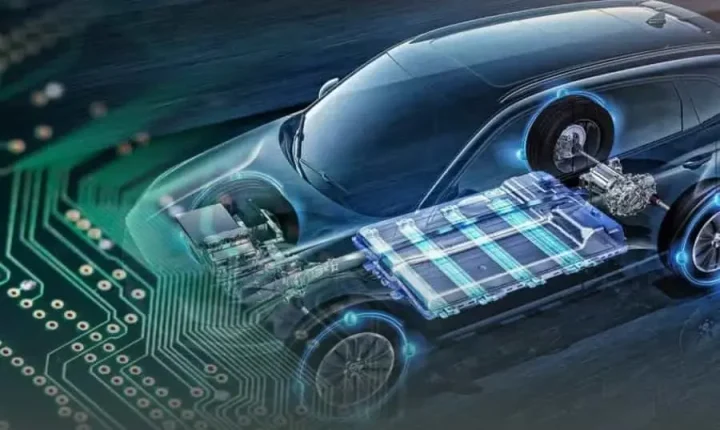

Advanced Driver Assistance Systems are revolutionizing modern vehicles. These systems rely heavily on high-performance Automotive PCBs to function seamlessly. From collision avoidance to adaptive cruise control, Automotive PCBs are the backbone of ADAS, ensuring real-time data processing and reliable connectivity. The demand for smarter, safer vehicles pushes automakers to integrate more sophisticated electronics. Automotive PCBs must meet stringent durability, heat […]

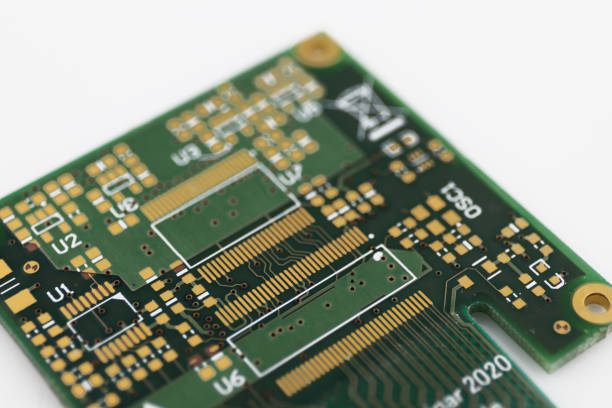

6-Layer SSD PCBs are becoming essential for faster, more efficient storage solutions. These PCBs play a significant role in high-speed data transfer, durability, and space efficiency. Whether for consumer devices or industrial use, understanding key design considerations for 6-layer SSD PCB is vital for optimal performance. Layer Stack-up and Its Impact on 6-Layer SSD PCB […]

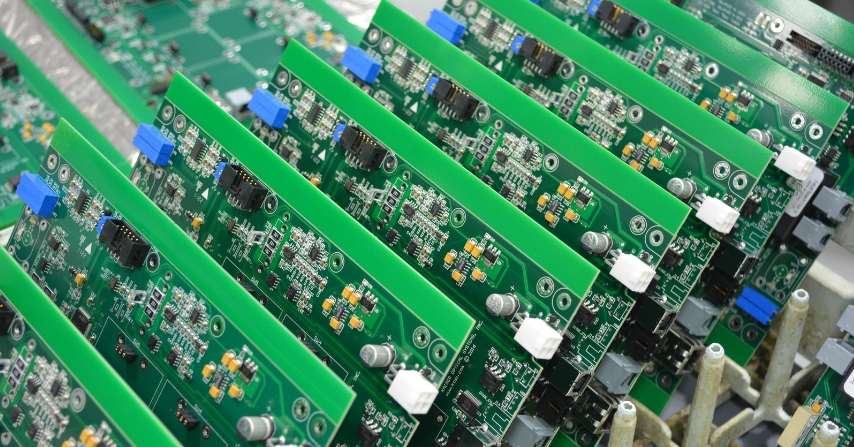

Set-top boxes (STBs) are the backbone of home entertainment, connecting users to streaming services, satellite TV, and smart home systems. At their core lies the Set-top Box PCB, a complex assembly that demands precision, reliability, and compliance with global safety standards. Traditional soldering methods relied on lead-based alloys for their low melting points and ease of […]