Cost vs. Performance: Finding the Right Balance in Set-Top Box PCB Design

The role of a Set-Top Box PCB is crucial in ensuring smooth device operation. It connects essential components like processors, memory, and tuners, providing seamless multimedia streaming. As consumer expectations grow, manufacturers must balance cost and performance. The choice of PCB materials, layout, and integration significantly impacts the device’s efficiency. Cost-effective designs help lower production expenses, but excessive cost-cutting may lead to performance bottlenecks. Striking the right balance ensures product reliability and market competitiveness. Therefore, understanding PCB design trade-offs is vital for manufacturers aiming for sustainability and profitability.

Material Selection for Set-Top Box PCB

Choosing the right materials for Set-Top Box PCBs is essential for achieving performance goals while maintaining cost efficiency. FR-4, a commonly used PCB material, provides a good balance between durability and affordability. However, high-end devices may require advanced materials like high-frequency laminates or metal-backed substrates for enhanced thermal management. While premium materials improve signal integrity and longevity, they also increase manufacturing costs. Manufacturers must assess their target market and functionality needs before selecting materials. Finding the optimal material ensures that the PCB can withstand long-term use without unnecessary expenses.

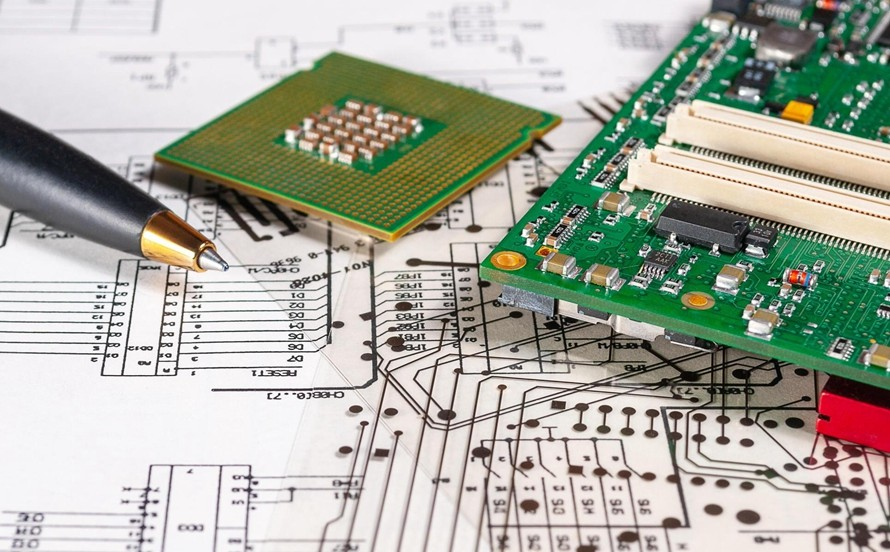

Optimizing Set-Top Box PCB Layout for cost-efficiency

PCB layout plays a significant role in determining both cost and performance. A well-optimized Set-Top Box PCB layout minimizes signal interference, reduces power consumption, and enhances heat dissipation. Efficient component placement can decrease the number of required layers, reducing production costs. However, an overly simplified layout may cause signal integrity issues, leading to data loss or hardware malfunctions. Designers should leverage simulation tools to analyze circuit behavior and optimize the layout accordingly. Achieving a cost-effective yet high-performance design requires PCB routing and component arrangement expertise.

Thermal Management Considerations

Heat dissipation is a critical factor in Set-Top Box PCB design. Insufficient thermal management can lead to overheating, reducing the device’s lifespan and reliability. Heat sinks, thermal vias, and copper pours can help manage temperature efficiently. However, incorporating advanced thermal solutions can drive up costs. A cost-effective approach involves strategically placing components with high heat output and ensuring proper ventilation. Engineers must consider the balance between affordable cooling solutions and long-term device stability. Effective thermal management prevents performance degradation and enhances overall user experience.

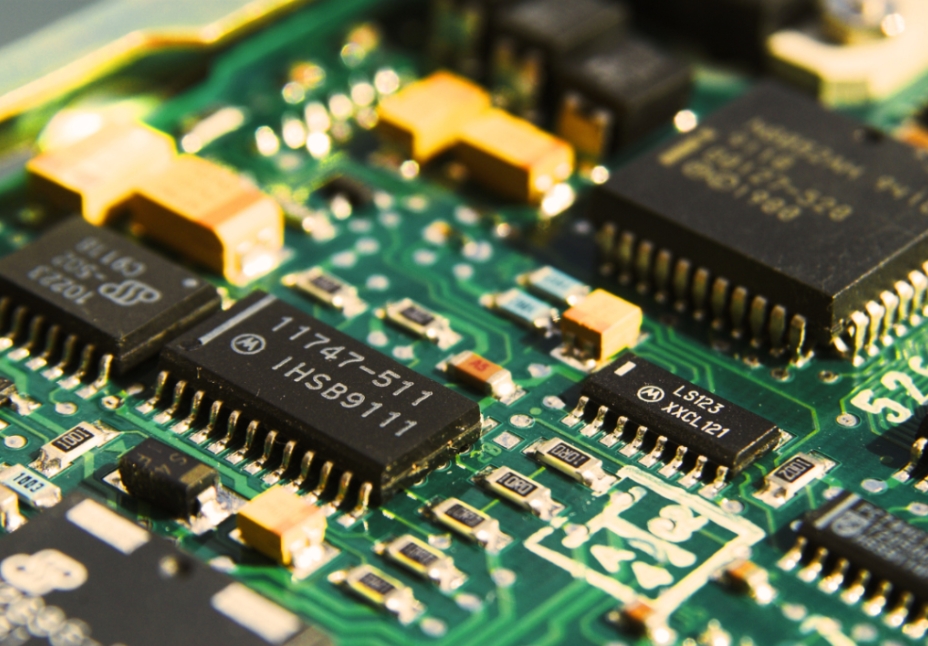

Component Selection and Integration

Selecting the right components significantly impacts both cost and performance. High-performance processors, memory chips, and tuners enhance user experience but can increase production costs. Manufacturers should evaluate alternative components that offer similar performance at a lower price. Additionally, integrating multiple functionalities into fewer components can help reduce board complexity and manufacturing expenses. Component selection must align with the device’s intended use and target audience. A strategic approach to component integration ensures that the final product meets performance standards without excessive spending.

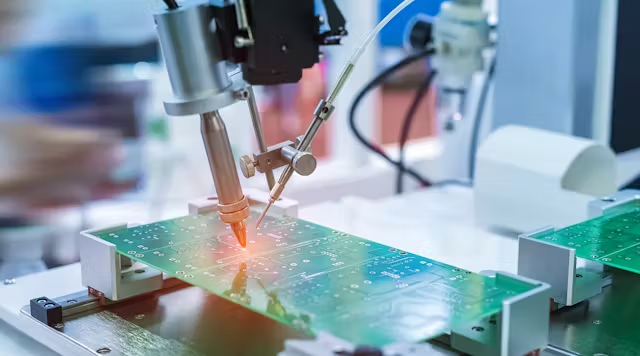

Manufacturing Process and Cost Efficiency

The choice of manufacturing techniques influences Set-Top Box PCB production costs. Surface-mount technology (SMT) is widely used for its efficiency and cost-effectiveness. However, complex PCB designs may require additional manufacturing steps, increasing costs. Partnering with experienced PCB manufacturers who offer bulk production and automation can help reduce expenses. Implementing design-for-manufacturing (DFM) principles also streamlines production and minimizes defects. Balancing performance with cost-effective manufacturing processes is key to achieving a competitive product in the market.

Testing and Quality Assurance

Ensuring quality in Set-Top Box PCB design is essential for reliability and customer satisfaction. Testing methods such as automated optical inspection (AOI) and in-circuit testing (ICT) help identify potential defects before mass production. While extensive testing adds to production costs, it prevents costly recalls and enhances brand reputation. Striking the right balance between thorough testing and cost control is crucial. A structured testing strategy minimizes failure rates and ensures long-term device performance, ultimately leading to higher consumer trust and reduced warranty claims.

Achieving the Ideal Cost-Performance Ratio in Set-Top Box PCB Design

Designing a Set-Top Box PCB requires careful cost and performance considerations. Each aspect affects the final product’s efficiency, from material selection and layout optimization to thermal management and component integration. While cost-cutting measures are necessary to maintain profitability, sacrificing performance can lead to poor user experience and market rejection. Manufacturers must leverage advanced design techniques and strategic sourcing to achieve an optimal balance. By maintaining a structured approach, companies can produce high-quality, cost-efficient PCBs that meet consumer expectations and industry standards.