Design Considerations for 6-Layer SSD PCB: A Comprehensive Guide OneSeine

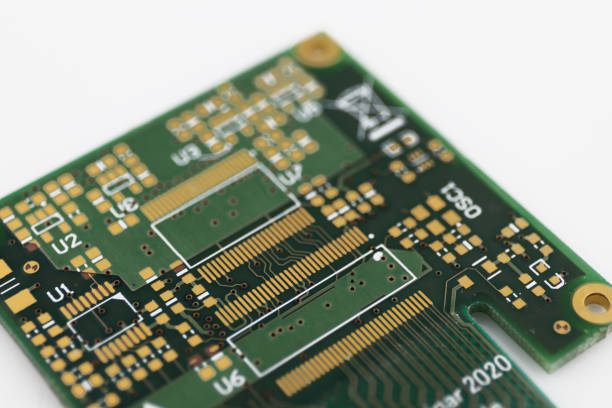

6-Layer SSD PCBs are becoming essential for faster, more efficient storage solutions. These PCBs play a significant role in high-speed data transfer, durability, and space efficiency. Whether for consumer devices or industrial use, understanding key design considerations for 6-layer SSD PCB is vital for optimal performance.

Layer Stack-up and Its Impact on 6-Layer SSD PCB Design

The layer stack-up in a 6-layer SSD PCB is a crucial decision. A typical stack-up involves layers for signal routing, power, and ground planes. Each layer’s placement directly impacts performance. For instance, ground planes reduce noise, ensuring stable performance.

When planning the stack-up, consider factors like signal integrity, power distribution, and shielding. A careful arrangement can minimize interference, optimize data transfer speeds, and improve overall durability. The final arrangement will play a large role in your SSD’s functionality and reliability.

Signal Integrity in PCB Design

Signal integrity is vital for 6-layer SSD PCBs, especially with high-speed data transmission. It ensures that signals travel without distortion or loss. This requires careful routing, trace lengths, impedance control, and the use of ground planes.

To ensure Integrity, use controlled impedance traces and avoid sharp corners or vias that could lead to signal reflection. Proper routing and a solid grounding system are essential for SSDs to prevent data loss and maintain performance. The more carefully you plan, the more reliable the final product will be.

Power Distribution and Grounding in 6-layer SSD PCB

Proper power distribution and grounding are vital for SSD PCBs. A six-layer design with separate power and ground layers helps reduce noise and prevent voltage fluctuations, ensuring stable operation.

When designing your PCB, separate power and ground planes for each section. This minimizes power noise, which can cause data corruption or slow performance. Proper grounding protects high-speed signals from electromagnetic interference, ensuring consistent data transfer for optimal performance.

Thermal Management in PCB Design

Thermal Management is a key consideration in 6-layer SSD PCBs. As SSDs process large amounts of data, they generate heat. Efficient heat dissipation methods, like thermal vias and heat sinks, are critical to preventing overheating.

Using thermal layers can significantly improve heat dissipation. Additionally, carefully positioning heat-sensitive components and ensuring proper airflow can help avoid thermal buildup. Addressing thermal challenges early is essential for maintaining the SSD’s longevity and reliability.

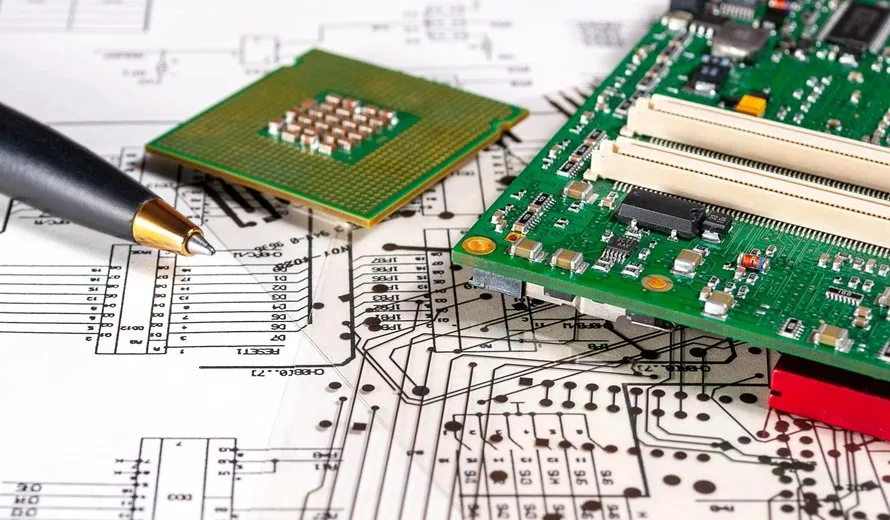

Advanced Materials for PCBs

Choosing the right materials for 6-layer SSD PCBs is crucial for both performance and durability. Advanced materials with lower dielectric constants and better thermal conductivity improve signal integrity, heat management, and board lifespan.

Materials like FR4 are commonly used, but high-performance devices often require more advanced substrates. Consider factors like operating temperature, moisture resistance, and mechanical strength when selecting materials. Using the right materials ensures the PCB meets the performance and durability needs of modern SSDs.

.png)

Design for Manufacturability and Cost-Efficiency

Designing a 6-layer SSD PCB with manufacturability in mind is critical for cost efficiency. The complexity of the design can drive up production costs, so balancing performance with manufacturability is key.

Design for manufacturability (DFM) aims to simplify the design and reduce issues during production. This includes optimizing trace widths, minimizing special handling layers, and positioning components for easy assembly. DFM helps identify potential problems early, saving time and money in production.

Final Thoughts on 6-Layer SSD PCB Design

Designing a 6-layer SSD PCB requires balancing performance, cost, and manufacturability. Key considerations include layer stack-up, signal integrity, power distribution, and thermal Management. Understanding these factors ensures the creation of high-performance SSDs suited to today’s digital demands.

By focusing on these principles and selecting quality materials, you can build a 6-layer SSD PCB that provides reliable, high-speed storage. As SSDs continue to be essential in computing, optimizing PCB design remains critical for cutting-edge performance.