Designing for High-Speed Performance with Rigid-Flex PCB

In today’s fast-paced electronics world, high-speed performance is not just a luxury; it’s a necessity. Engineers and designers are constantly challenged with developing cutting-edge devices that can handle complex tasks at lightning speeds. One of the most innovative solutions to achieve this is using Rigid-Flex PCB technology. But how exactly can it be used to design for high-speed performance? In this blog, we’ll explore the intricacies of designing with Rigid-Flex PCB to meet high-speed requirements.

What Makes High-Speed Electronics So Challenging

Rapid technological advancements drive the demand for high-speed performance in modern electronics. Devices must process vast amounts of data in real time while maintaining reliability and efficiency. This is particularly challenging because high-speed circuits tend to generate more heat, increase signal interference, and require precise alignment between components. These challenges are amplified when dealing with small, compact devices, where space limitations and complexity demand an optimal design.

In traditional circuit boards, managing high-frequency signals and ensuring signal integrity often requires elaborate designs and external components. However, Rigid-Flex PCBs provide a solution by offering rigid and flexible attributes in a single board, which is crucial for minimizing these challenges. By integrating flexibility into the design, high-speed circuits can be optimized for performance without compromising the form factor.

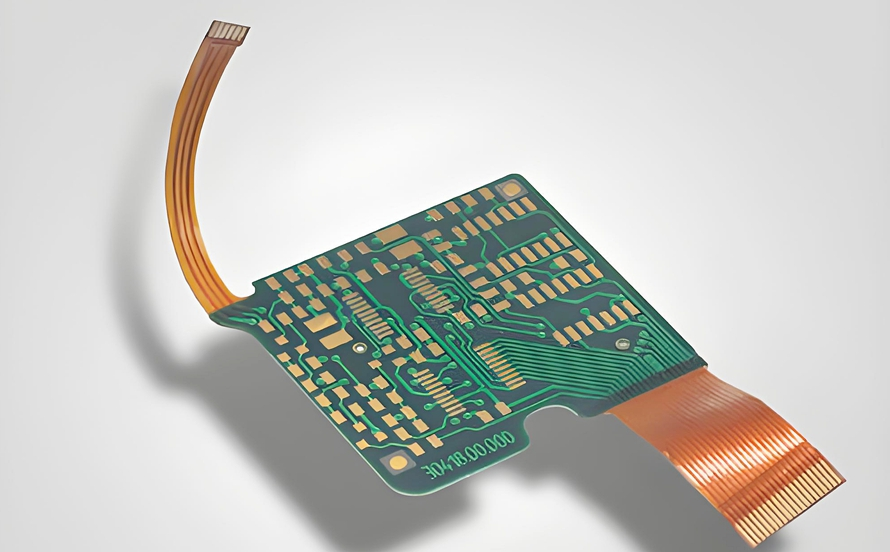

The Role of Rigid-Flex PCB in High-Speed Design

The Rigid-Flex PCB is a hybrid design that combines the strength and stability of rigid PCBs with the versatility and space-saving advantages of flexible PCBs. This hybrid approach is ideal for high-speed performance, as it allows for precise signal routing and optimized layout, reducing noise and signal loss, which are often issues in high-speed designs.

Using Rigid-Flex PCBs, designers can place components in previously impossible or impractical locations with traditional rigid boards. This flexibility ensures that high-frequency signals travel the shortest distance, minimizing delays and improving overall performance. Additionally, Rigid-Flex PCB designs enable complex routing, reducing the need for vias and allowing for cleaner, more direct signal paths.

How to Improve Performance and Ensure Signal Integrity

Signal integrity is one of the most critical factors in designing high-speed electronics. As circuits’ speeds increase, so does the risk of signal degradation due to issues like electromagnetic interference (EMI) and crosstalk between signals. For high-speed designs, managing these issues is vital to maintaining performance and ensuring reliable operation.

Rigid-flex PCB technology addresses this by providing the flexibility to precisely control the layout of the traces, minimize the distance between components, and ensure the paths are as direct as possible. Additionally, the materials used in Rigid-Flex PCBs—such as high-performance laminates—can be tailored to minimize loss and improve signal fidelity. Combining rigid and flexible components allows for more robust designs, where signal integrity is better maintained even at high frequencies.

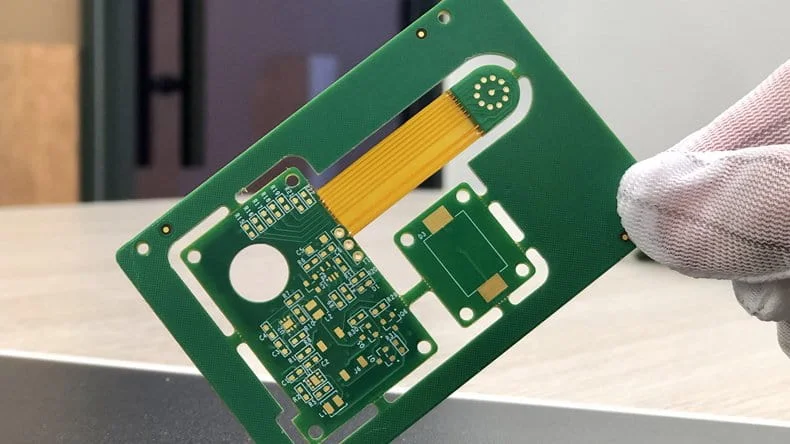

The Power of Layer Stacking in Rigid-Flex PCB

One of the standout features of Rigid-Flex PCBs in high-speed design is their ability to accommodate multiple layers. Layer stacking in Rigid-Flex PCB designs allows for more efficient signal routing and better management of high-speed signals. By placing high-speed signals in inner layers, designers can isolate them from external interference, improving performance.

Layer stacking also enables designers to create multi-layer circuits in compact spaces without sacrificing speed or reliability. This is especially beneficial in applications with size constraints, such as wearable technology, smartphones, and IoT devices. The versatility of Rigid-Flex PCBs enables designers to optimize signal routing for high-speed performance while keeping the overall design small and efficient.

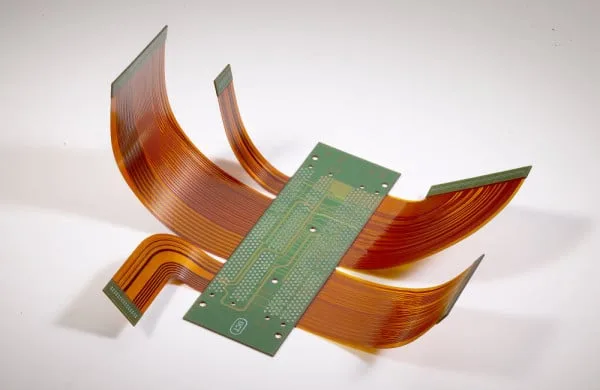

High-Speed Performance in Harsh Environments

High-speed electronics often operate in demanding conditions, from extreme temperatures to physical stress. Whether it’s an aerospace application or a medical device that needs to function in extreme environments, Rigid-Flex PCBs offer a significant advantage. Their durability makes them perfect for high-speed designs that operate in harsh environments without losing performance.

In rugged applications, the flexible nature of Rigid-Flex PCB ensures that the board can withstand mechanical stress and vibrations while maintaining high-speed performance. Creating robust, durable, lightweight designs is crucial in the automotive, military, and aerospace industries, where reliability and speed are non-negotiable.

Cost-Effective Designs without Compromising Performance

While high-speed designs typically demand expensive materials and components, Rigid-Flex PCBs can offer a more cost-effective solution. By combining rigid and flexible elements in one board, designers can reduce the number of components and layers required, ultimately lowering the overall cost of the product. This reduction in complexity can also shorten production time and reduce errors during manufacturing.

Despite these cost savings, the performance of Rigid-Flex PCBs doesn’t suffer. The board’s ability to deliver high-speed performance with reduced signal loss and interference means the final product operates more efficiently. This cost-effective solution is beautiful for companies looking to produce high-performance devices without exceeding their budget.

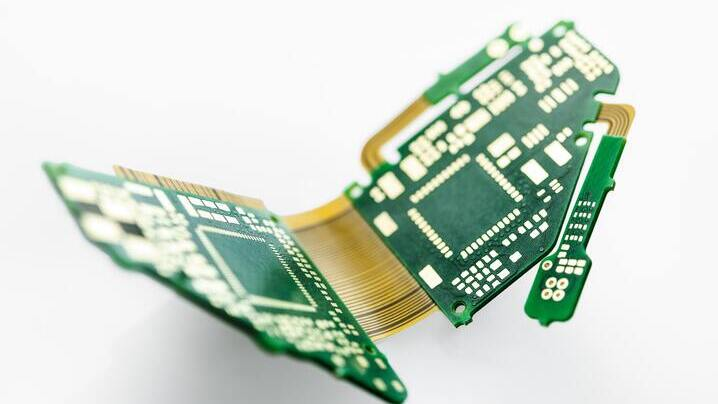

Simplify Design and Reduce Design Complexity

Designing high-speed electronics often involves complex routing, multiple components, and the need for precision. Rigid-flex PCBs help streamline the design process by reducing the need for complex interconnects and external components. The flexibility to route signals more efficiently significantly simplifies the overall design.

By utilizing Rigid-Flex PCBs, designers can optimize their products’ electrical and mechanical aspects in a single step. Reducing complexity speeds up the design process and enhances product reliability, as fewer components and connections mean fewer potential failure points. This simplicity is essential when designing high-speed devices that require precision and durability.

Future of High-Speed Electronics and Rigid-Flex PCB

The future of high-speed electronics is closely linked to developing innovative materials and advanced PCB designs. As technologies such as 5G, autonomous vehicles, and AI-driven systems evolve, the demand for faster, more efficient circuits will only increase. Rigid-Flex PCBs are well-positioned to meet these demands, thanks to their ability to support high-speed performance in compact, durable packages.

We expect further advancements in Rigid-Flex PCB materials, design capabilities, and manufacturing techniques. These innovations will make designing high-speed, high-performance electronics across various industries easier. As the push for faster, more innovative devices continues, Rigid-Flex PCBs will remain a key enabler of next-generation technology.

Rigid-Flex PCBs Provide Efficient Solutions for the High-Speed Electronics Industry

Designing for high-speed performance presents various challenges, from signal integrity to component placement. However, Rigid-Flex PCBs offer a versatile, cost-effective solution that addresses these issues while maintaining high levels of reliability and performance. By combining the strengths of both rigid and flexible designs, Rigid-Flex PCBs allow engineers to meet the demands of high-speed electronics across multiple industries.

As technology continues to evolve, the role of Rigid-Flex PCBs in high-speed design will only become more critical. Whether for consumer electronics, medical devices, or aerospace systems, Rigid-Flex PCBs provide a reliable platform for designing compact, high-performance devices. By leveraging the unique properties of Rigid-Flex PCBs, engineers can push the boundaries of what’s possible in high-speed electronics, ensuring that the devices of tomorrow can perform at the speed of innovation.