Gold Finger PCB and Industry 4.0: Enabling Smart Manufacturing

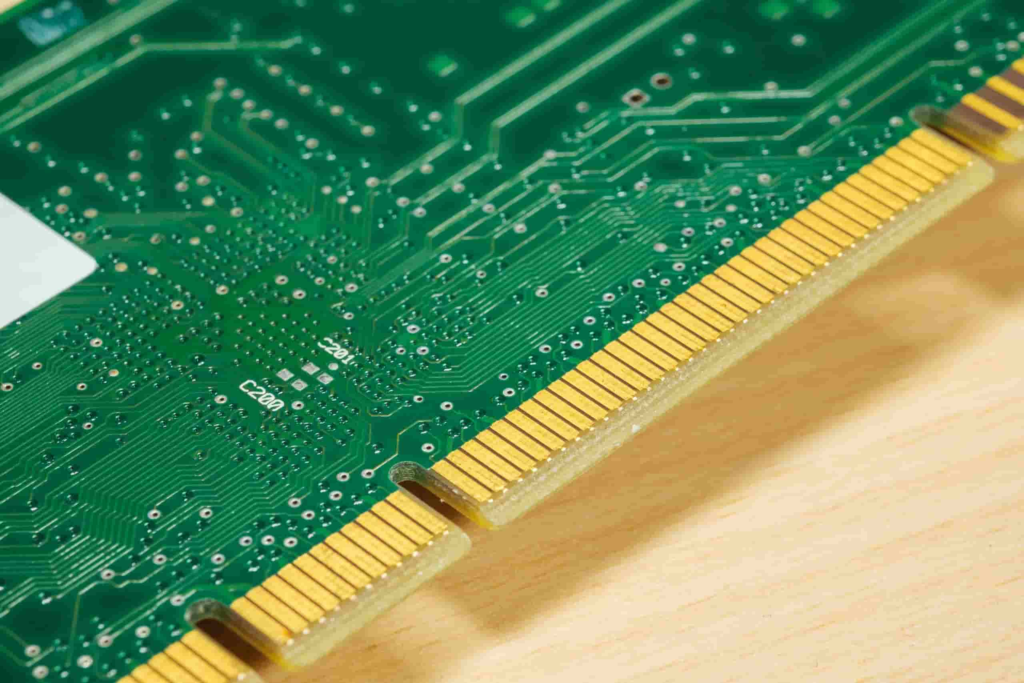

The Fourth Industrial Revolution, or Industry 4.0, transforms manufacturing by integrating advanced technologies like IoT, AI, and automation. At the heart of this transformation lies a critical component: the Gold Finger PCB. With their gold-plated edge connectors, these specialized printed circuit boards are pivotal in enabling smart manufacturing. They ensure reliable connectivity, high-speed data transfer, and durability in harsh industrial environments. In this blog, we’ll explore how Gold Finger PCBs are driving the evolution of Industry 4.0 and revolutionizing modern manufacturing processes.

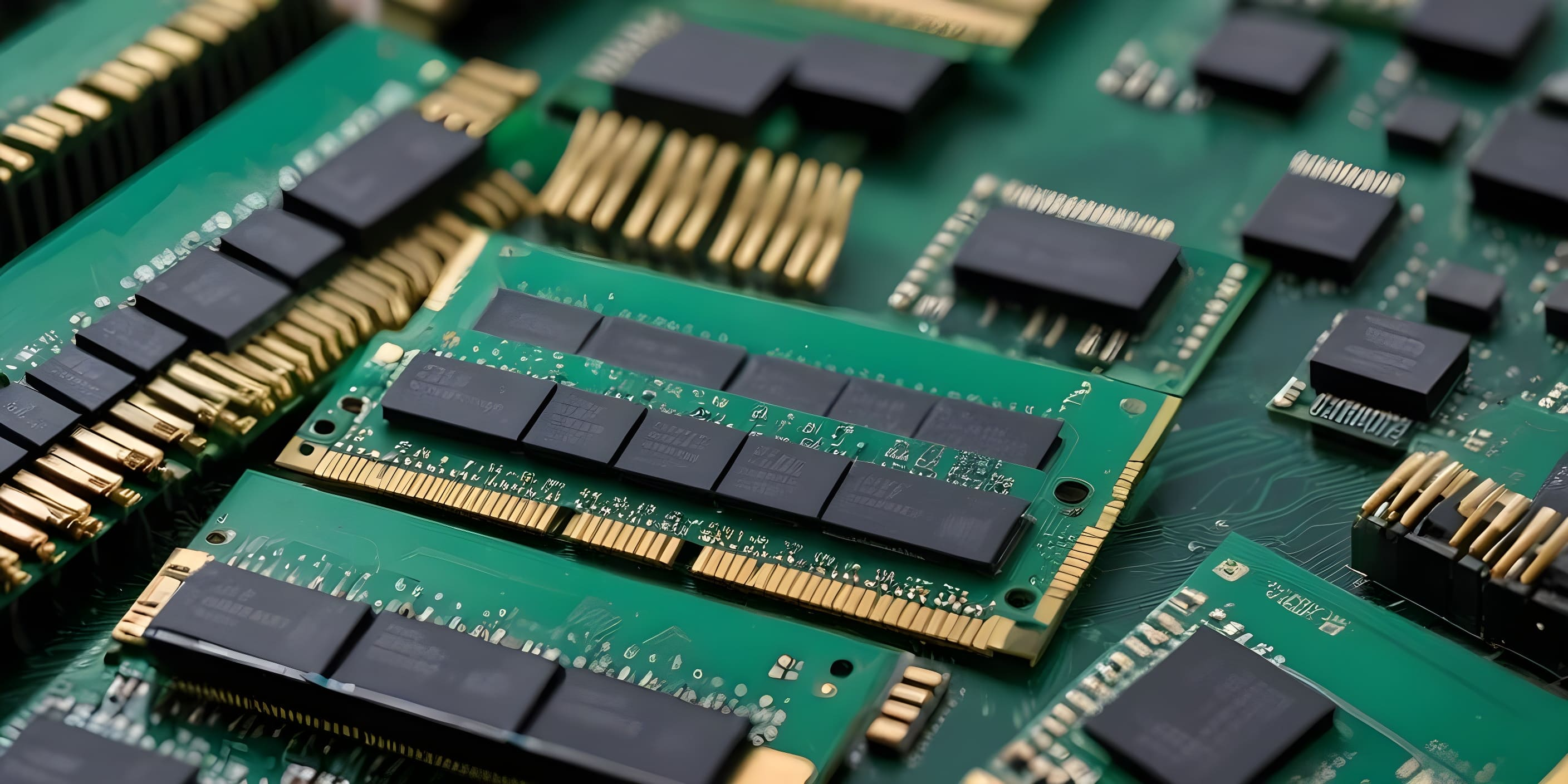

The Role of Gold Finger PCB in Smart Factories

Smart factories rely on seamless communication between machines, sensors, and control systems. Gold Finger PCBs are essential for this connectivity. Their gold-plated connectors provide excellent conductivity and resistance to corrosion, ensuring reliable performance even in demanding conditions. For example, Gold Finger PCBs enable high-speed data exchange between robotic arms and central control units in automated assembly lines.

Moreover, their durability reduces maintenance needs, minimizing downtime and boosting productivity; according to a report by MarketsandMarkets, the global smart manufacturing market is expected to grow at a CAGR of 12.4% from 2021 to 2026. Gold Finger PCBs are a key enabler of this growth, supporting the integration of advanced technologies into manufacturing processes.

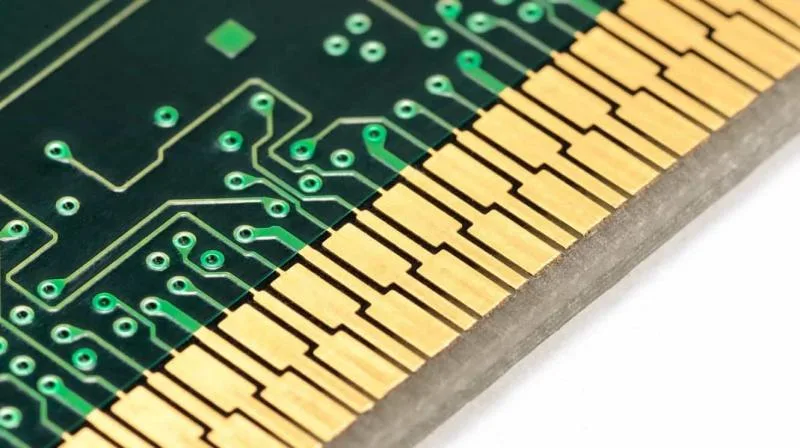

Enhancing Data Transfer Speeds in Industry 4.0

In Industry 4.0, real-time data is crucial for decision-making and process optimization. A gold Finger PCB excels in high-frequency signal transmission, making it ideal for fast and accurate data transfer applications. For instance, in predictive maintenance systems, sensors collect data on machine performance and send it to analytics platforms via Gold Finger PCB.

The gold plating on these PCBs minimizes signal loss and interference, ensuring data integrity. This capability is critical in environments with high electromagnetic interference (EMI). As a result, manufacturers can monitor equipment health in real-time, preventing costly breakdowns and improving efficiency.

Durability and Reliability in Harsh Environments

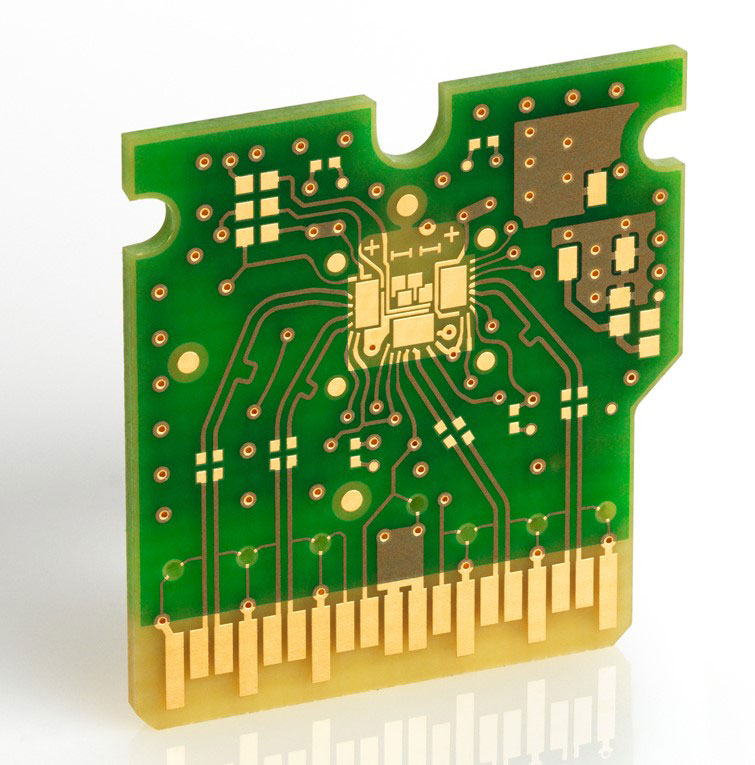

Manufacturing environments can be harsh, with exposure to dust, moisture, and temperature fluctuations. Gold Finger PCBs are designed to withstand these challenges. The gold plating on the connectors resists oxidation and wear, ensuring long-term reliability.

For example, in the automotive industry, Gold Finger PCB is used in diagnostic equipment and assembly line robots. These applications demand components that can operate consistently under extreme conditions. Gold Finger PCB provides robust performance, helping manufacturers maintain high production standards and reduce equipment failures.

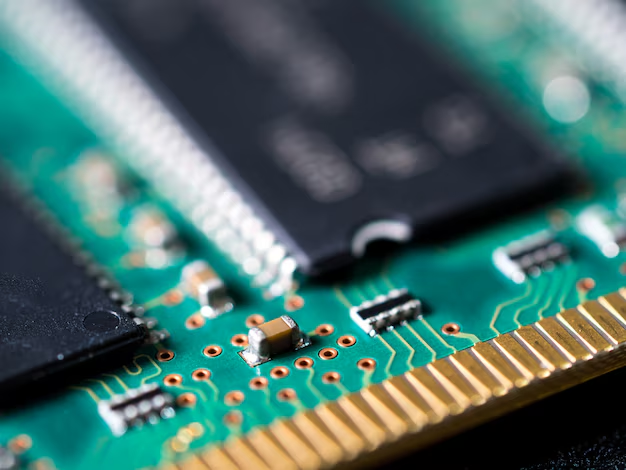

Gold finger PCB enables IoT integration in manufacturing

The Internet of Things (IoT) is a cornerstone of Industry 4.0, connecting devices and systems to create a networked manufacturing ecosystem. Gold Finger PCBs facilitate this integration by providing reliable connections for IoT devices.

In smart factories, IoT sensors collect data on everything from temperature to machine performance. This data is transmitted via Gold Finger PCBs to centralized systems for analysis. For instance, Siemens uses IoT-enabled systems with Gold Finger PCBs to optimize factory energy consumption, reducing costs and environmental impact.

Supporting Automation and Robotics

Automation is a key feature of Industry 4.0, and Gold Finger PCBs are integral to its success. They provide the connectivity needed for robotic systems to function efficiently. For example, robots equipped with Gold Finger PCBs in electronics manufacturing can assemble components precisely and quickly.

These PCBs also support collaborative robots (cobots) working alongside human operators. By ensuring reliable communication between cobots and control systems, Gold Finger PCBs enhance safety and productivity on the factory floor.

Driving Innovation in Additive Manufacturing

Additive manufacturing, or 3D printing, is another area where Gold Finger PCBs are making an impact. They are used in the control systems of 3D printers, ensuring precise movement and operation. For example, Stratasys, a leading 3D printing company, uses Gold Finger PCBs in its industrial printers to achieve high levels of accuracy and repeatability.

As additive manufacturing becomes more widespread, the demand for reliable and high-performance PCBs will continue to grow. Gold Finger PCBs are well-positioned to meet this demand, driving innovation in this rapidly evolving field.

The Future of Gold Finger PCBs in Industry 4.0

As Industry 4.0 continues to evolve, the role of Gold Finger PCBs will become even more critical. Advances in materials science and manufacturing techniques are making these PCBs more efficient and cost-effective. For instance, researchers are exploring using nanotechnology to enhance the performance of gold plating.

Moreover, integrating AI and machine learning into manufacturing processes will require even faster and more reliable data transmission. Gold Finger PCBs will be at the forefront of this transformation, enabling more intelligent and connected factories.

Why Gold Finger PCB Is Essential for Industry 4.0

Gold Finger PCBs are a cornerstone of Industry 4.0, enabling the seamless integration of advanced technologies into manufacturing processes. Their reliability, durability, and high-performance capabilities make them indispensable in smart factories. From enhancing data transfer speeds to supporting IoT and automation, Gold Finger PCBs are driving the future of manufacturing. We provide PCB design solutions; contact us to build your own gold finger PCB.