How are the power and ground planes distributed in an 8 layer SSD PCB?

8 layer SSD PCB design emphasizes the critical role of power and ground plane distribution in high-performance multi-layer PCBs, particularly for SSDs.The quality of the underlying PCB largely determines the efficiency of SSDs, which are data storage devices. 8 layer SSD PCBs provide enhanced signal integrity, power delivery, and grounding, making them well-suited for complex, high-speed devices like SSDs. This blog will explore the significance of power and ground plane distribution in 8 layer SSD PCBs, detailing their construction and design considerations.

Importance of 8 layer SSD PCB Layers

An 8 layer SSD PCB is a printed circuit board with eight layers of copper for routing signals and distributing power and ground. SSDs that replace traditional hard drives must be fast, efficient, and reliable, and PCBs play a massive role. Increasing the number of layers improves signal integrity, power distribution, and thermal performance. Engineers sandwich power and ground planes between signal layers in a multi-layer design like 8-layer SSD PCBs, ensuring optimal current flow and reliable device operation.

For SSDs that require high-speed data transmission, having more layers means better control of impedance and reduced crosstalk between signal layers. In addition, power and ground planes are essential to avoid noise, ensure clean power delivery, and aid the overall operation of the SSD. Each layer in an 8 layer SSD PCB has a specific role, and adequately distributing power and ground planes is essential to support high-speed, stable operation.

Importance of Power and Ground Planes

A critical element that makes an 8 layer SSD PCB stand out is the presence of dedicated power and ground planes. These planes provide a low-resistance path for current, essential for high-speed SSDs. The power plane distributes power to various components, while the ground plane serves as a reference voltage for signal integrity and reduces electromagnetic interference.

In 8 layer SSD PCBs, dedicated power and ground planes ensure that voltage is evenly distributed between different layers. This reduces the likelihood of power shortages to critical components such as the SSD controller, NAND flash memory, and other essential ICs. Additionally, the ground plane acts as a shield for the signal layer, preventing noise and reducing the likelihood of signal degradation. Separating signal, power, and ground planes in PCB layout improves reliability and stability, especially in high-frequency applications like SSDs.

The Role of Layer Stackup Power and Ground Plane Distribution

The layer stack in an 8 layer SSD PCB is carefully planned to ensure optimal performance. An 8 layer stack typically consists of multiple signal layers, ground planes, and power planes. A typical stack might look like this: Signal 1 (top), Ground Plane 1, Signal 2, Power Plane, Ground Plane 2, Signal 3, Ground Plane 3, Signal 4 (bottom). By placing power and ground planes between signal layers, we create a design that minimizes noise and crosstalk between adjacent signal lines.

This stackup ensures uniform power delivery throughout the SSD. The separation between the power and ground planes also reduces EMI and improves the overall efficiency of power delivery. By optimizing the power and ground plane layout, designers can improve the reliability and thermal management of the SSD. Proper layer stack up in an 8 layer SSD PCB ensures that high-speed signals are isolated and noise is minimized, thereby improving the performance and lifespan of the device.

Design of Ground Plane Distribution

Ground planes are critical in designing any multi-layer PCB, and their role is even more crucial for an 8 layer SSD PCB. Ground planes are a reference for all signals, helping prevent noise, maintain signal integrity, and reduce interference from external sources. In an 8-layer SSD PCB, designers typically place ground planes next to the power plane and signal layers to ensure effective noise suppression and return current paths.

One of the main advantages of having multiple ground planes in an 8 layer SSD PCB is that they help shield high-frequency signals. In addition, ground planes allow the ground potential to be evenly distributed across the PCB. This is particularly important in SSDs requiring high-speed data transmission and low latency. Ensuring that the ground plane is distributed correctly can help prevent voltage drops and improve the overall performance of the SSD. A well-designed ground plane can also enhance thermal management, dissipating heat more effectively and ensuring consistent performance.

Power Plane Distribution in 8 layer SSD PCB

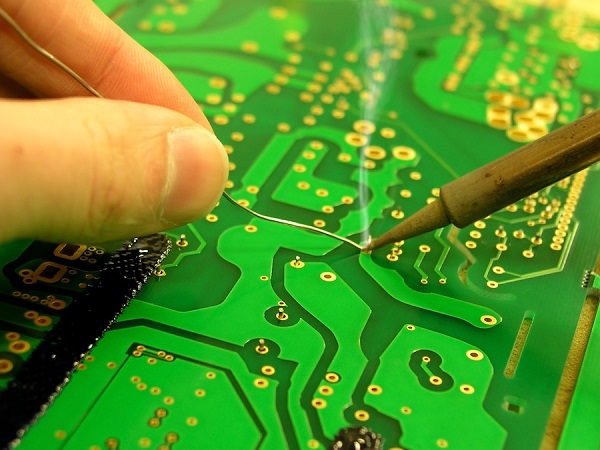

The power plane in an 8 layer SSD PCB provides clean and stable voltages to all components. SSDs rely on various power supplies, such as 3.3V, 1.8V, and even lower for some low-power circuits. Engineers must efficiently route these different voltage levels on the PCB to ensure that each component receives the correct voltage with minimal noise and voltage drop.

In an 8-layer SSD PCB, designers typically sandwich the power plane between ground planes or signal layers. This arrangement reduces parasitic inductance and ensures even power delivery throughout the board. By optimizing the power plane layout, designers can reduce noise and EMI generated by the switching power supplies within the SSD. An adequately distributed power plane also helps extend the life of the SSD, ensuring that the device operates efficiently under different workloads and environmental conditions.

EMI Reduction and Signal Integrity

One of the main advantages of using an 8 layer SSD PCB is its ability to reduce electromagnetic interference (EMI) and improve signal integrity. SSDs operate at high frequencies, and interference or noise can cause data corruption or performance degradation. By carefully distributing power and ground planes, designers can minimize EMI and ensure clean and distortion-free signal transmission.

Ground planes adjacent to signal layers in an 8 layer SSD PCB ensure that high-frequency signals have a clear return path, minimizing the possibility of signal reflections or crosstalk. This is especially important in SSDs, where data integrity is critical. Also, power and ground planes provide proper EMI shielding to help maintain signal integrity, even in electrically noisy environments. This enables faster data transfer rates, higher performance, and more reliable SSDs.

Thermal Management and Reliability of 8 layer SSD PCBs

In addition to providing a stable power and signal environment, power distribution and ground planes in an 8 layer SSD PCBs also play a crucial role in thermal management. SSDs generate heat, especially when processing extensive data or operating at high speeds. With dedicated power and ground planes, engineers can dissipate heat generated by components more effectively, reducing the overall temperature of the SSD.

Proper thermal management ensures that the SSD operates reliably over the long term and extends the life of the device. Overheating is one of the leading causes of SSD failure, and by effectively distributing power and ground planes, designers can reduce this risk. A well-designed 8 layer SSD PCB coupled with proper thermal management ensures the SSD operates within its optimal temperature range, improving performance and lifespan.

Optimizing Power and Ground Planes for Optimal Performance

The distribution of power and ground planes in an 8 layer SSD PCB is critical in ensuring SSD performance, reliability, and lifespan. Proper layer stackup and careful attention to the placement of power and ground planes reduce noise, minimize EMI, and improve signal integrity. In addition, a well-distributed power and ground plane design aids in thermal management, ensuring that the SSD operates within a safe temperature range, even under heavy loads.