How Ceramic PCB Is Enabling the Next Generation of High-Power LED Lighting

The lighting industry is revolutionizing, driven by the demand for brighter, more efficient, and longer-lasting solutions. Ceramic PCB technology is at the heart of this transformation—a game-changer for high-power LED systems. Unlike traditional materials like FR4 or aluminum, Ceramic PCBs offer unmatched thermal management, durability, and electrical performance. From smart city streetlights to industrial-grade fixtures, Ceramic PCBs are enabling LEDs to operate at peak efficiency while pushing the boundaries of innovation. Let’s explore how this technology is lighting the way forward.

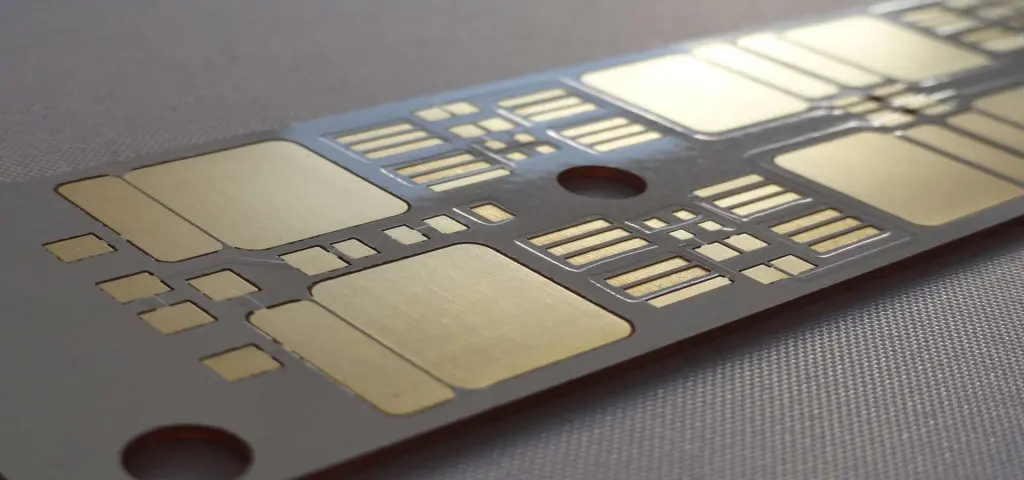

Ceramic PCB: Superior Thermal Management

High-power LEDs generate significant heat, destroying performance and lifespan if not appropriately managed. Ceramic PCBs excel here thanks to their exceptional thermal conductivity. Materials like aluminum oxide (Al₂O₃) and aluminum nitride (AlN) dissipate heat up to 10x faster than conventional substrates, according to a 2023 study by the International Journal of Electronics.

For example, Osram’s Duris S 8 LED modules use Ceramic PCBs to maintain junction temperatures below 85°C even at 200W loads. This prevents thermal throttling and ensures consistent brightness. By efficiently channeling heat away from sensitive components, Ceramic PCBs enable LEDs to operate at higher power levels without compromising reliability.

Material Advantages: Durability Meets Precision

Ceramic PCBs are inherently robust, making them ideal for harsh environments. Their resistance to corrosion, moisture, and chemical exposure ensures long-term stability—a critical factor for outdoor and industrial lighting.

Take Cree’s XLamp® LEDs, which leverage Ceramic PCBs for mining and marine applications. These boards withstand temperature fluctuations from -40°C to 150°C, far exceeding the limits of traditional materials. A 2022 report by MarketsandMarkets highlighted that the global Ceramic PCB market will grow at a CAGR of 9.8% through 2028, driven by demand for ruggedized electronics.

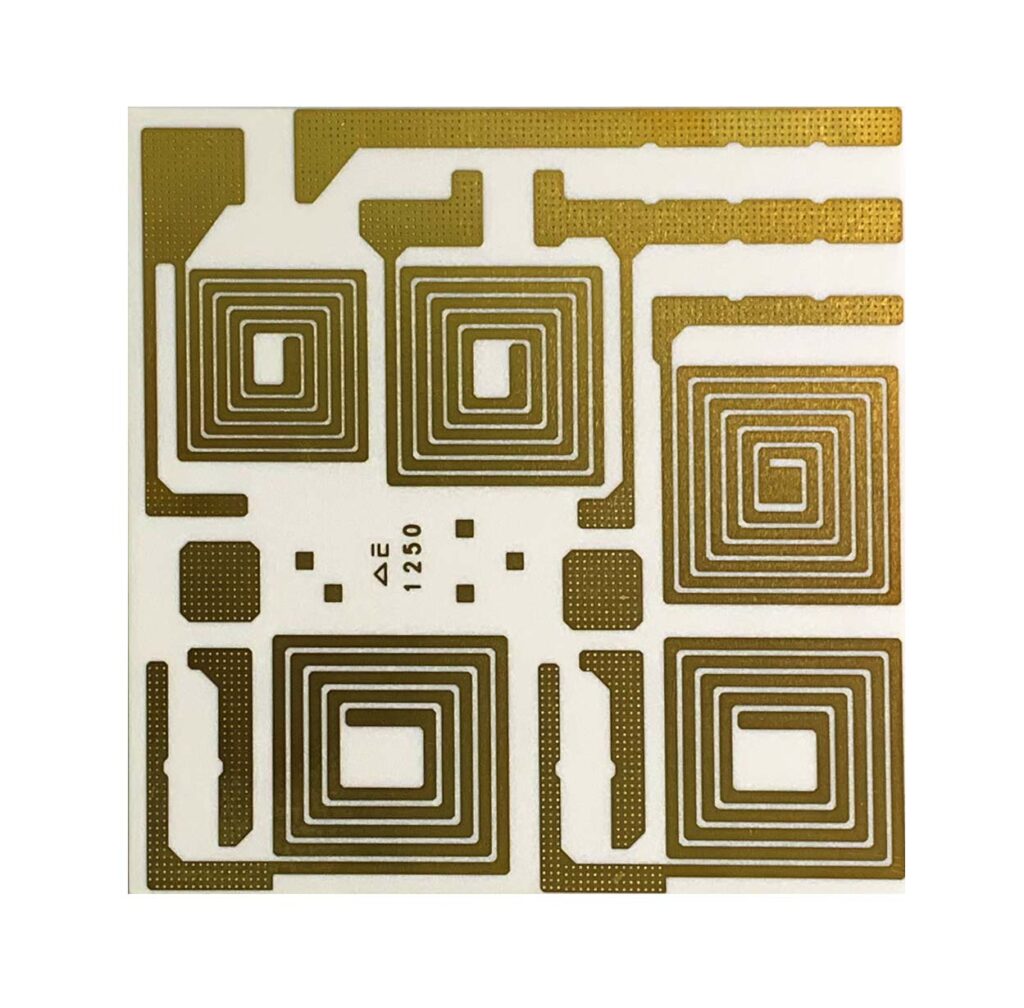

Design Flexibility: Enabling Compact, High-Density Systems

Ceramic PCBs support intricate designs and miniaturization, which is crucial for next-gen LED lighting. Their ability to handle fine-pitch traces and multilayer configurations allows engineers to pack more LEDs into smaller spaces.

For instance, Philips’ Color Kinetics line uses Ceramic PCBs to create ultra-slim architectural lighting panels. These boards enable precise control over light distribution while reducing the fixture’s footprint. Additionally, Ceramic PCBs’ compatibility with advanced soldering techniques ensures strong bonds for high-density LED arrays.

Case Study: Smart Street Lighting with Ceramic PCB

Cities like Barcelona and Singapore are adopting smart LED streetlights powered by Ceramic PCBs. These systems integrate sensors, wireless controls, and adaptive lighting—all demanding reliable thermal and electrical performance.

A pilot project in Berlin reduced energy consumption by 60% using Ceramic PCB-based LEDs, as reported by the European Commission in 2023. The boards’ durability also slashed maintenance costs by 45%, showcasing their economic and environmental benefits.

Enhanced Lifespan: Reducing Total Cost of Ownership

According to a 2021 IEEE paper, LEDs on Ceramic PCBs last up to 100,000 hours—double the lifespan of those on aluminum boards. This longevity stems from reduced thermal stress on components, minimizing failure rates.

For businesses, this translates to lower replacement costs and downtime. A Walmart case study revealed that switching to Ceramic PCB-driven LEDs in warehouses cut lighting-related expenses by 35% over five years.

Sustainability: Aligning with Green Initiatives

Ceramic PCBs support eco-friendly LED lighting in two key ways. First, their durability reduces electronic waste, and second, their efficiency lowers energy consumption.

For example, Ceramic PCBs in horticultural LEDs enable vertical farms to use 50% less power than traditional lighting, according to a 2023 Agritech Tomorrow report. Additionally, Ceramic’s recyclability aligns with circular economy goals, making it a preferred choice for ESG-focused companies.

Ceramic PCBs light the way to the future

Ceramic PCB technology will remain indispensable as high-power LED applications expand—from automotive headlights to UV sterilization. Its unique blend of thermal efficiency, durability, and design flexibility addresses the core challenges of modern lighting systems.

Industry leaders like Nichia and Lumileds are investing in next-gen Ceramic PCB solutions to support 500W+ LED arrays. With advancements in 3D-printed ceramics and embedded cooling channels, the future looks brighter than ever.