How do Heavy Copper PCB improve power distribution in electronic devices?

Power distribution is critical to electronic devices, and as technology advances, electronic devices must manage higher power demands, requiring systems that can handle these loads without sacrificing efficiency or performance. Effective power distribution ensures businesses evenly distribute electrical energy throughout the device, reducing the risk of energy loss, overheating, and component failure. Heavy copper PCB is essential in improving power distribution in modern electronic systems. These specially designed boards feature thicker copper layers, allowing them to manage higher current loads without the common issues of power loss, heat buildup, and resistance. As a result, heavy copper PCBs help improve power delivery efficiency, reduce the risk of heat damage, and improve equipment’s overall reliability in various applications. This article focuses on how heavy copper PCB can contribute to efficient power distribution in high-power electronic devices.

Power Distribution Challenges in High-Performance Electronics

Effective power distribution within an electronic device is crucial for maintaining consistent performance and ensuring long-term reliability. Power distribution involves delivering electricity from the source (such as a battery or power supply) to components like processors, memory units, and peripherals. If businesses do not distribute power efficiently, devices can suffer from voltage drops, reduced performance, and increased heat generation, negatively impacting overall functionality.

Heavy Copper PCB helps address these challenges by offering a more efficient method of power distribution. The thick copper layers used in these PCBs reduce the resistance within the board, allowing for the smooth flow of current to sensitive components. As a result, the device’s power system operates more efficiently, delivering consistent power to every part of the device. In high-performance electronics, such as power supplies, electric vehicles, and industrial control systems, where power loads are heavier, Heavy Copper PCB ensures that power distribution is optimized for peak performance and longevity.

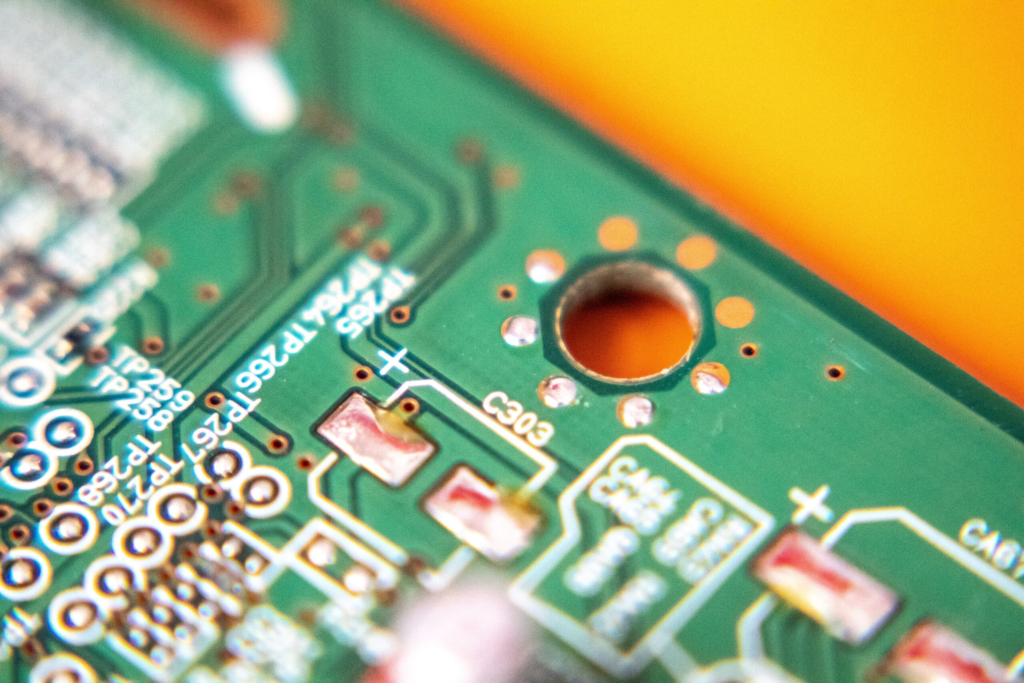

The Role of Copper Thickness in Power Distribution

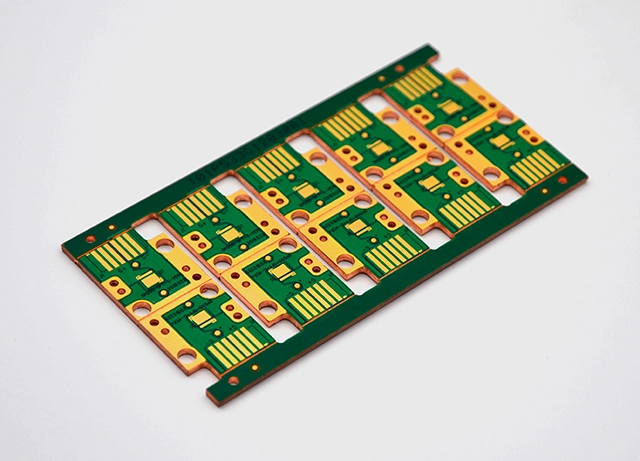

PCB manufacturers use copper as the primary material, and its thickness directly impacts the board’s current carrying capacity. Traditional PCBs typically use copper thicknesses ranging from 1 oz to 3 oz per square foot. This is sufficient for many low- to mid-power applications but becomes inadequate for high-power devices, where thicker copper is needed to handle the increased current flow without overheating or causing damage.

In Heavy Copper PCB, the copper thickness can range from 3 oz to as much as 20 oz per square foot. This increased thickness helps lower the electrical resistance within the board, facilitating better current flow and improving power distribution. The thicker copper ensures the device can handle high current loads without significant power loss, allowing for smoother operation and reducing the risk of component damage due to inadequate power delivery. This makes Heavy Copper PCBs ideal for power electronics, automotive systems, and other devices requiring efficient power distribution at higher currents.

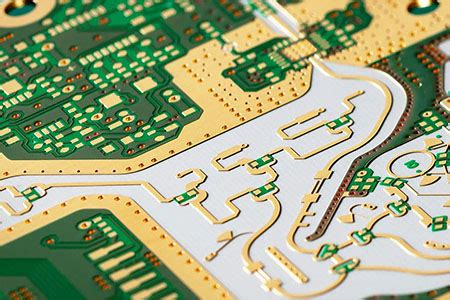

Lower Resistance for Better Power Efficiency

One of the most significant benefits of Heavy Copper PCB is its ability to reduce resistance within the power distribution system. Resistance in a circuit results in energy loss, typically heat, which can decrease efficiency and harm sensitive components. Heavy Copper PCB decreases the overall resistance by using thicker copper layers, ensuring power is distributed more efficiently and with minimal loss.

The reduction in resistance prevents unnecessary energy waste and ensures that more power reaches the components that need it most. For instance, in high-power applications such as power supplies for industrial machines or battery management systems for electric vehicles, efficient power distribution is essential for maintaining performance and extending the life of the device. By reducing energy loss and improving efficiency, Heavy Copper PCB contributes to more sustainable and cost-effective devices, which is increasingly essential in today’s energy-conscious world.

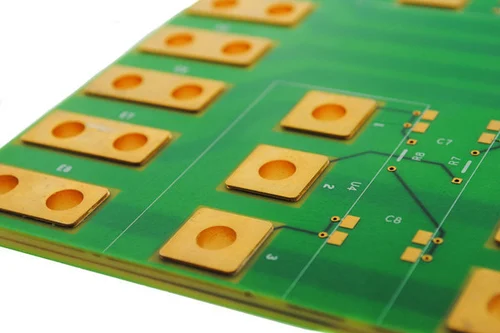

Improved Thermal Management with Heavy Copper PCB

Heat generation is a common issue in high-power electronics. As power flows through a PCB, systems with high current demands inevitably lose some energy as heat Excessive heat can damage components, reduce efficiency, and lead to premature failure. Proper thermal management ensures that devices can handle high power loads without compromising performance.

Heavy Copper PCB is known for its superior thermal management capabilities. The thicker copper layers help dissipate heat more efficiently across the board, preventing localized hotspots and ensuring the entire device stays within safe temperature limits. Overheating can lead to serious issues in power-sensitive applications, such as power electronics, automotive systems, or even telecommunications equipment. By using Heavy Copper PCB, manufacturers can ensure that their devices operate within optimal temperature ranges, extending their lifespan and improving overall reliability. This level of thermal control is crucial for high-performance devices that operate under demanding conditions.

Enhancing Reliability and Longevity with Heavy Copper PCB

Reliability is one of the most essential factors in designing electronic devices, especially those used in critical applications like aerospace, automotive, and medical systems. Components that experience power surges, heat buildup, or inconsistent power distribution are likelier to fail prematurely. Distributing power efficiently and safely across the board helps businesses mitigate the risks associated with component failure, improving the device’s overall reliability.

Heavy Copper PCB improves the longevity of electronic devices by providing better power handling capabilities, reducing the likelihood of thermal failure or power-related damage. These boards can handle higher current loads using thicker copper layers without suffering from the common overheating issues and power loss that can plague traditional PCBs. This increased durability is particularly beneficial in industries where downtime and component failure, such as automotive or medical applications, can have significant financial and safety implications. Ultimately, the enhanced reliability offered by Heavy Copper PCB leads to longer-lasting, more robust devices.

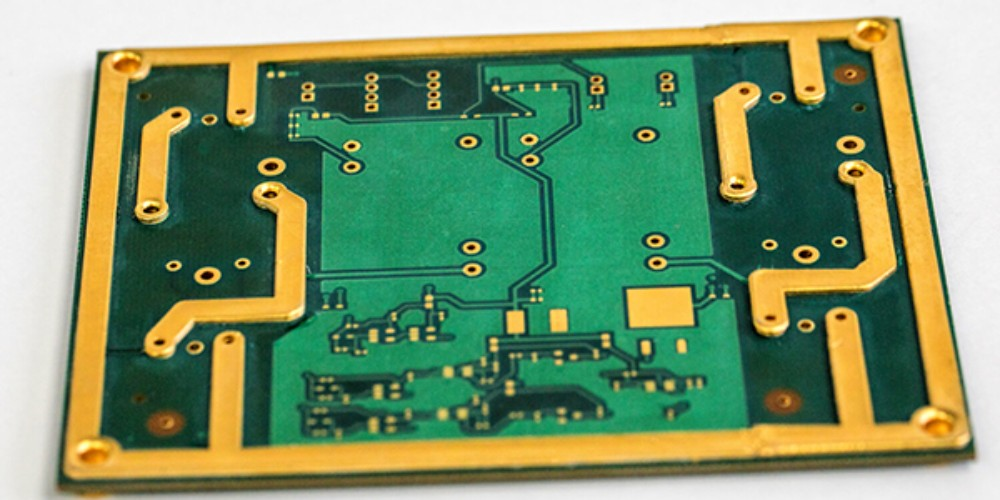

Customization for Specific Power Needs

Every electronic application has unique power requirements, which can vary based on factors like the type of components used, the device’s form factor, and its operating environment. As a result, power distribution solutions need to be highly customizable to meet the specific needs of the device. Heavy Copper PCB offers an excellent solution to this challenge by allowing manufacturers to tailor the copper’s thickness, the traces’ width, and the overall layout to optimize power distribution for each application.

For instance, in industries like electric vehicles (EVs), where power management is crucial for battery life and vehicle performance, Heavy Copper PCB can be designed to handle the high current requirements of EV charging systems, battery management circuits, and power inverters. The ability to customize the design ensures that the PCB can accommodate the specific power needs of the system while maintaining efficiency and reducing waste. Customization allows businesses to integrate the PCB better with the overall thermal management strategy of the device, ensuring effective power distribution without overheating.

Future Trends in Power Distribution with Heavy Copper PCB

As the demand for more efficient, compact, and powerful electronic devices rises, businesses are positioning Heavy Copper PCBs to play a critical role in meeting these needs. As technologies like electric vehicles, renewable energy, and high-performance computing evolve, the requirements for efficient power distribution will only grow more complex. Heavy Copper PCBs, with their superior power handling and thermal management capabilities, will continue to be at the forefront of innovations in power electronics.

We expect further advancements in Heavy Copper PCB manufacturing techniques, including developing more efficient designs, new materials, and improved customization options. These advancements will help meet the increasing power demands of next-generation devices while ensuring that they remain energy-efficient, reliable, and durable. Heavy Copper PCB will be essential for delivering the power solutions needed to support these innovations as industries push the boundaries of what is possible in electronics.

The Impact of Heavy Copper PCB on Power Distribution

The importance of efficient power distribution in modern electronic devices cannot be overstated, as power demands increase across various industries. Heavy Copper PCB offers a valuable solution by providing enhanced power handling, improved thermal management, and excellent reliability in high-power applications. Their ability to reduce resistance, dissipate heat, and handle higher currents makes them a critical component in devices where efficiency, longevity, and safety are essential.