How do Heavy Copper PCB improve the efficiency of power distribution systems?

Power distribution systems are critical to the performance and reliability of electronic devices, machinery, and networks. As industry demands more energy-efficient systems, the materials used in power distribution components must evolve. Heavy copper PCB is a crucial innovation in this regard, with thicker copper layers that can handle high currents while preventing heat buildup—two critical factors in improving the efficiency and reliability of power distribution systems. In this article, we’ll explore how heavy copper PCBs enhance the performance of power distribution systems, their advantages over standard PCBs, and why they are becoming a top choice across industries.

The Difference Between Heavy Copper PCB and Standard PCB

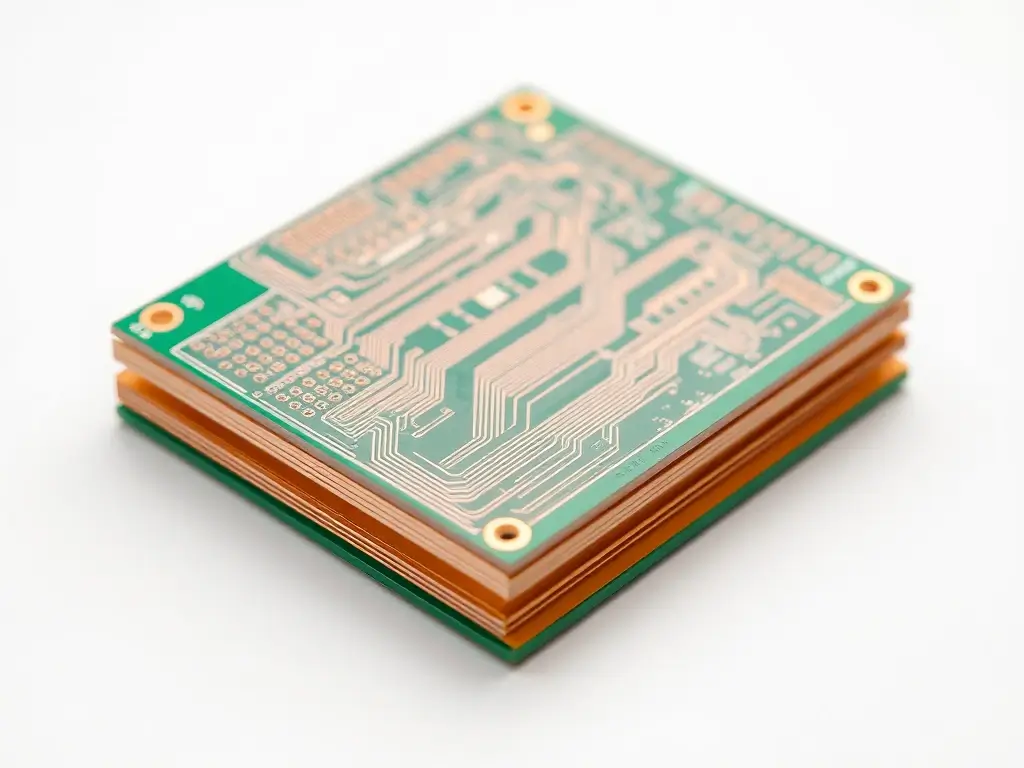

Heavy Copper PCBs stand out from traditional printed circuit boards due to their significantly thicker copper layers. While standard PCBs typically use copper thicknesses ranging from 1 ounce per square foot to 2 ounces per square foot, Heavy Copper PCBs use copper thicknesses of 3 ounces per square foot and above, with some designs even reaching up to 15 ounces per square foot or more. This unique feature enables Heavy Copper PCBs to handle higher currents, a crucial factor in power distribution systems where high-power circuits are standard.

This increased copper thickness enables Heavy Copper PCBs to handle higher currents, essential in power distribution systems where high-power circuits are standard. These thicker copper layers ensure that the board can carry larger electrical loads without overheating, thus improving the overall performance and longevity of the system. In contrast, standard PCBs with thinner copper layers may struggle to manage high-power applications due to their inability to effectively dissipate heat.

Furthermore, the enhanced copper thickness in Heavy Copper PCBs allows for more precise current distribution, which helps reduce energy loss and improve the efficiency of the power distribution system. By increasing the copper thickness, manufacturers can reduce the resistance in the circuit, leading to more efficient power transfer and minimizing the risk of circuit failure caused by heat buildup.

Improving Heat Dissipation and Preventing Thermal Issues in Power Distribution Systems

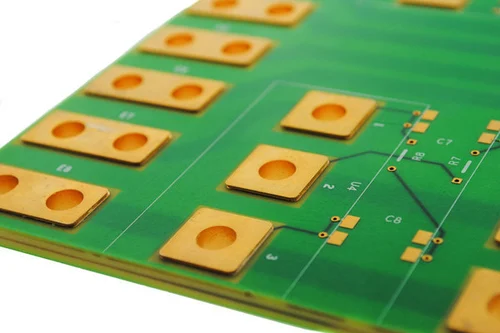

One of the most significant challenges in power distribution systems is managing the heat generated by electrical currents. When electrical current passes through a conductor, it generates heat due to resistance. If not properly managed, this heat can cause components to degrade over time, reduce system efficiency, and even lead to failure.

Heavy Copper PCBs significantly improve thermal management by providing thicker copper traces, which helps to dissipate heat more effectively. With higher thermal conductivity, Heavy Copper PCBs can distribute the heat generated by high currents across the board’s surface more efficiently. This helps to prevent hot spots that could damage sensitive components, ensuring that the power distribution system operates within safe temperature limits.

Moreover, using thicker copper layers in Heavy Copper PCBs can help reduce the board’s thermal expansion. Excessive thermal expansion can cause the PCB to warp, which could lead to poor electrical connections and circuit failure. By reducing this risk, Heavy Copper PCBs enhance power distribution systems’ long-term reliability and efficiency.

Role in Improving Power Efficiency in Industrial Systems

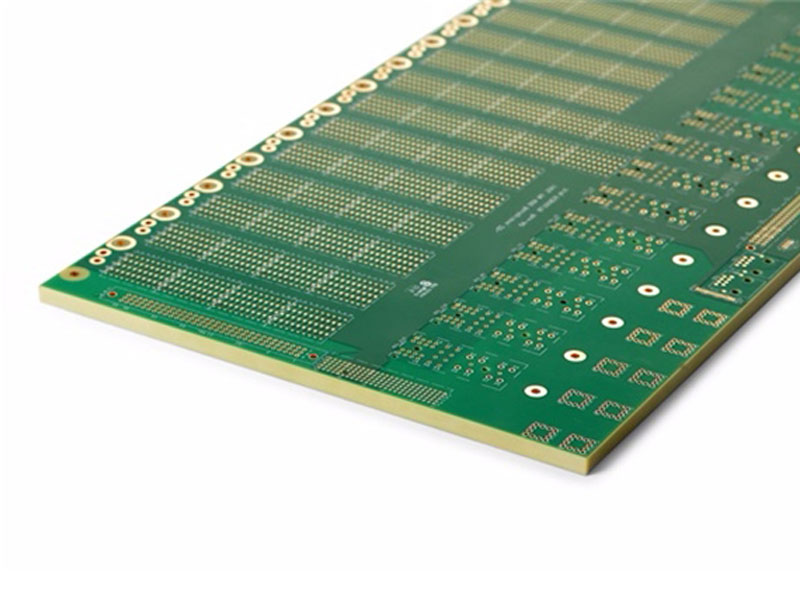

Heavy Copper PCBs play a pivotal role in improving power efficiency in industrial applications such as machinery, automation, and robotics. These systems require peak efficiency to ensure smooth, continuous equipment operation. By allowing for more efficient power transfer, reducing energy loss, and minimizing heat generation, heavy Copper PCBs are increasingly used in these environments, thereby enhancing the overall performance of power distribution systems.

Manufacturers can improve energy efficiency by using heavy copper PCBs in these systems and reducing the resistance in power distribution circuits. This is particularly important in industrial systems, where even small reductions in energy loss can result in significant cost savings. As power requirements continue to increase in industries like automation and robotics, Heavy Copper PCBs provide the necessary infrastructure to support these demands.

Boosting Efficiency in Renewable Energy Systems’ Power Distribution

The demand for more efficient power distribution systems has grown as the world moves toward renewable energy sources. Heavy Copper PCB is becoming increasingly essential for distributing the electrical power generated from these sources in renewable energy systems like solar panels and wind turbines.

Solar panels, for example, often generate high currents that must be efficiently transferred to inverters or batteries for storage and use. By using Heavy Copper PCBs in the power distribution circuits of solar panel systems, manufacturers can reduce energy losses, improve overall efficiency, and ensure that the generated power is effectively utilized.

Similarly, in wind turbines, Heavy Copper PCBs can manage the high currents generated by the turbine’s motor and distribute power to the grid. The high thermal conductivity of these PCBs ensures that the power distribution system remains efficient even under high loads, preventing overheating and reducing the risk of system failure.

Enhancing Automotive Power Distribution for Electric and Hybrid Vehicles

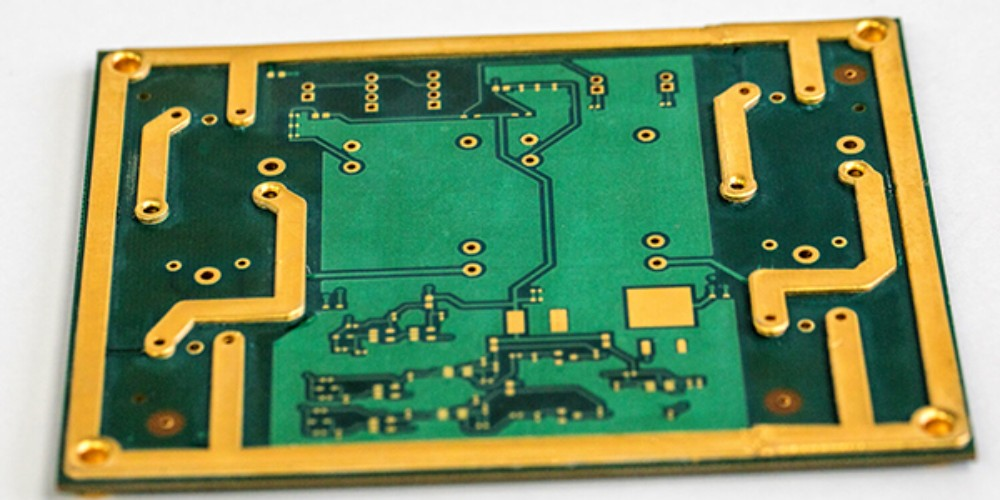

The automotive industry is witnessing a surge in demand for advanced electronics as vehicles become more electrically powered. From electric vehicles (EVs) to advanced driver-assistance systems (ADAS), automotive power distribution systems must efficiently handle high currents while ensuring safety and reliability. Heavy Copper PCBs, with their ability to handle the high power demands of modern automotive systems, are proving to be an ideal solution for these applications.

Heavy Copper PCB is ideal for automotive applications because it can handle the high power demands of modern automotive systems. In electric vehicles, for example, Heavy Copper PCBs can be used to manage the power distribution from the battery to the motor and support other electrical components like lighting, sensors, and entertainment systems.

In EV charging stations, Heavy Copper PCBs manage the high currents required for fast charging. By using Heavy Copper PCBs, manufacturers can ensure that power is distributed safely and efficiently, reducing energy loss and enhancing the vehicle’s or charging infrastructure’s overall performance.

Boosting Long-Term Reliability and Durability in Power Systems

A power distribution system’s long-term reliability and durability are essential for ensuring uninterrupted performance. Systems that experience frequent failures or need constant maintenance can be costly to repair and may even cause safety hazards.

Heavy Copper PCBs address these concerns by offering superior durability and longevity. The thicker copper layers allow them to withstand higher currents without the risk of burnout and provide a more robust platform for high-power applications. This ensures that power distribution systems operate smoothly over time, even under high-demand conditions.

Moreover, the superior thermal management provided by Heavy Copper PCBs prevents overheating and reduces the likelihood of component failure due to excessive temperatures. This makes them a highly reliable choice for systems that require continuous, uninterrupted power, such as medical devices, industrial machinery, and communication networks.

Heavy Copper PCB are Critical to Future Power Distribution Systems

Heavy copper PCBs are becoming the solution of choice as the demand for more energy-efficient, reliable, and high-performance power distribution systems increases across industries. Their ability to handle high currents, prevent heat buildup, and improve overall power transmission efficiency makes them valuable components in various applications, from industrial systems to renewable energy, automotive electronics, and more. By incorporating heavy copper PCBs in power distribution systems, manufacturers can ensure that their systems are efficient and reliable, future-proofed, and able to handle the increasing power demands of future technologies.