How Do I Choose the Right Power Supply PCB for High-Power Applications?

In high-power applications, selecting the appropriate power supply, PCB is essential for ensuring system stability, reliability, and efficiency. Power supply PCBs serve as the backbone of electronic devices by converting and regulating electrical power for other components. This task becomes even more critical in high-power applications due to the increased demands on voltage, current, and heat dissipation. In this article, we will explore how to choose the proper power supply PCB for high-power applications, considering key factors like performance, size, thermal management, and safety.

Understanding the Requirements for High-Power Applications

Before selecting a power supply PCB, it’s crucial to understand the specific needs of the high-power application. High-power systems often require PCBs capable of handling large amounts of current and ensuring efficient energy conversion. A power supply PCB in motor control needs higher power ratings than one in consumer electronics.

These systems often operate under demanding conditions, requiring efficient energy management and thermal control to prevent overheating. Knowing the power rating, voltage, current requirements, and environmental factors helps in narrowing down the best power supply PCBs for the job. It is also essential to consider the system’s load type and whether the power needs to be distributed across multiple components or concentrated in a single area.

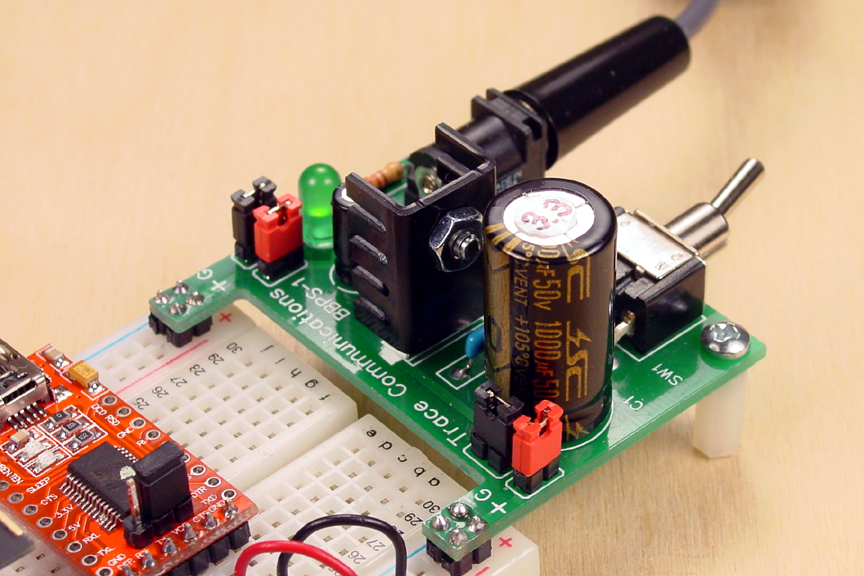

Thermal Management Considerations for High-Power PCBs

Thermal management is one of the most important factors to consider when choosing a power supply PCB for high-power applications. High-power devices generate heat, and without proper heat dissipation, components can overheat, causing failure or reduced efficiency. The power supply PCB must be designed to handle the heat generated during operation.

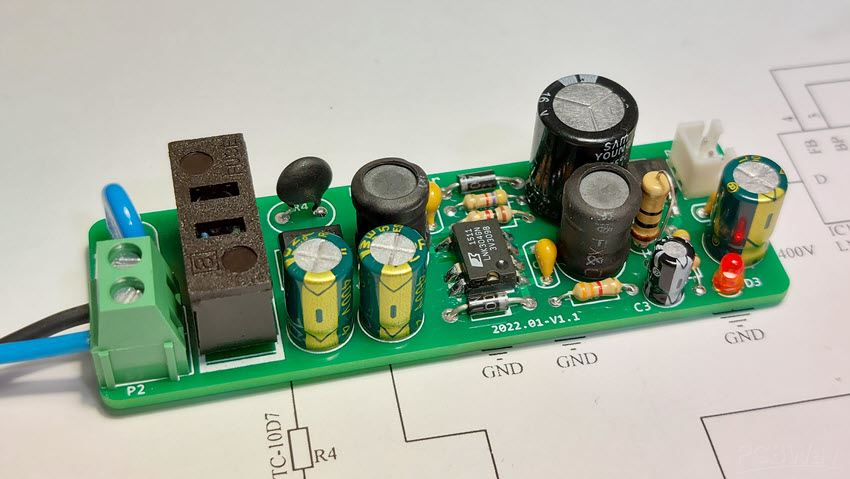

Power supply PCBs are often equipped with heat sinks, copper traces, and thermal vias to manage heat effectively. These features allow for better heat distribution and help maintain the integrity of the components. Additionally, selecting a power supply PCB with an appropriate surface area for heat dissipation is essential. Proper thermal management ensures the system’s longevity, stability, and safe operation.

Choosing the Right Materials for High-Power PCBs

The materials used in the power supply PCBs play a significant role in its performance. For high-power applications, materials must withstand voltage, current, heat, and mechanical stress. High-performance power supply PCBs often use materials like FR4, Rogers, or other high-temperature laminates, which are designed to withstand the demanding conditions of high-power systems.

The choice of copper thickness in the PCB also affects its power-handling capabilities. Thicker copper traces allow for higher current flow, reducing resistance and heat generation. The dielectric material must have a high breakdown voltage to prevent insulation failure, avoiding arcing and short circuits in high-power applications.

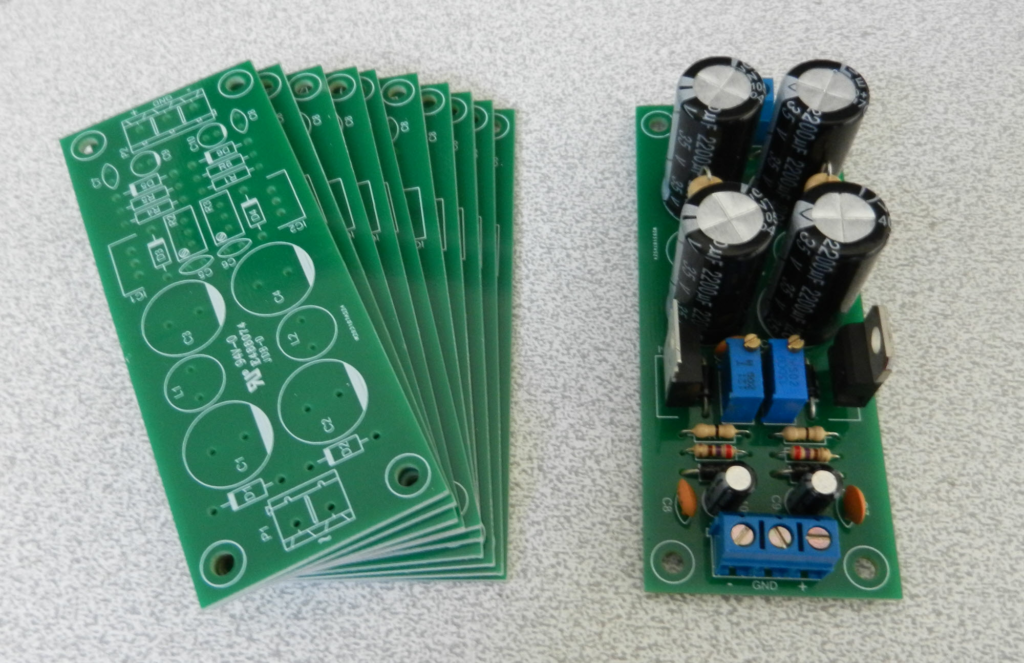

Size and Layout Optimization for High-Power Applications

The layout and size of the power supply PCB are critical factors in determining its performance, especially for high-power systems. Efficient PCB design ensures that components are correctly placed to minimize resistance, reduce electromagnetic interference (EMI), and improve heat distribution.

For high-power applications, the power supply PCBs must be designed to handle both the power requirements and the device’s physical constraints. The layout should be optimized for maximum efficiency, minimizing signal loss and ensuring that power is distributed effectively across the system. Additionally, smaller and more compact designs are necessary for applications with limited space, such as electric vehicles or portable energy storage systems. In comparison, larger designs might be used in systems with higher power demands.

Safety Features in Power Supply PCB

Safety is paramount in high-power applications. A power supply PCB must be designed to prevent overvoltage, overcurrent, and short circuits. These safety features protect the PCB and other connected components, ensuring the system runs reliably and safely.

To improve safety, many power supply PCBs include protection circuits, such as fuses, diodes, or circuit breakers, to prevent component damage from excessive voltage or current. Furthermore, components like surge protectors and transient voltage suppressors (TVS) are often incorporated into high-power PCBs to protect against power surges. Integrating safety features into the power supply PCB design prevents costly damage and improves system reliability.

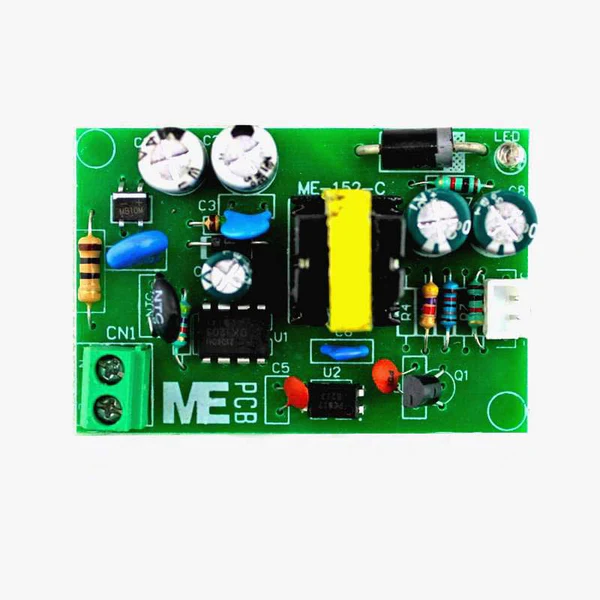

Efficiency and Power Conversion in High-Power PCBs

Efficiency is a key factor when selecting power supply PCBs for high-power applications. A high-efficiency power supply minimizes energy loss, reduces heat generation, and improves the overall system performance. Efficiency is especially critical in applications like renewable energy systems, where maximizing power conversion and minimizing energy loss directly impact system performance.

For high-power applications, it’s essential to choose a power supply PCB that integrates efficient power conversion technologies, such as DC-DC converters, linear regulators, and switching power supplies. These components ensure high energy efficiency, maximizing power use for the application and minimizing heat loss. Efficient power conversion reduces the need for large, bulky cooling systems, ultimately lowering the overall system cost.

Future-Proofing Your Power Supply PCB Selection

When selecting power supply PCBs for high-power applications, it’s essential to consider not just current needs but also future expansion and upgrades. High-power systems evolve quickly, and technologies are constantly improving to meet higher energy demands, reduce environmental impact, and enhance performance. Therefore, choosing a scalable and adaptable power supply PCB is essential for future-proofing your system.

Look for power supply PCBs that support modular designs and can be easily upgraded with the latest components or features. Consider future power requirements and ensure that the selected PCB can accommodate potential increases in load, voltage, and current needs. Future-proofing ensures that the system will remain efficient and reliable even as your application evolves.

Choosing the Best Power Supply PCB for High-Power Needs

Selecting the proper power supply PCBs for high-power applications involves a thorough understanding of the system’s requirements, including thermal management, material choices, layout design, and safety features. By considering factors such as power handling capacity, efficiency, and future scalability, businesses can ensure that their power supply PCBs meet both current and future demands.

At MZH Electronics, we offer specialized power supply PCBs designed to meet the rigorous demands of high-power applications. Our solutions combine advanced technology, superior materials, and high-efficiency designs to deliver exceptional performance and reliability. Contact us today to find the perfect power supply PCB for your high-power application needs.