How do the prices of aluminium PCBs compare to those of FR4 PCBs?

In PCBs, material selection plays a key role in determining performance and cost. Among the various materials used, aluminium PCBs and FR4 PCBs are two common choices, each with unique advantages and cost implications. For manufacturers, understanding how the price of aluminium PCBs compares to that of FR4 PCBs is critical to making an informed decision that balances performance, durability, and budget.

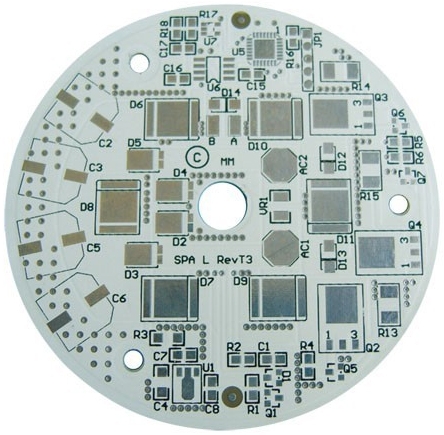

What Are Aluminium PCBs?

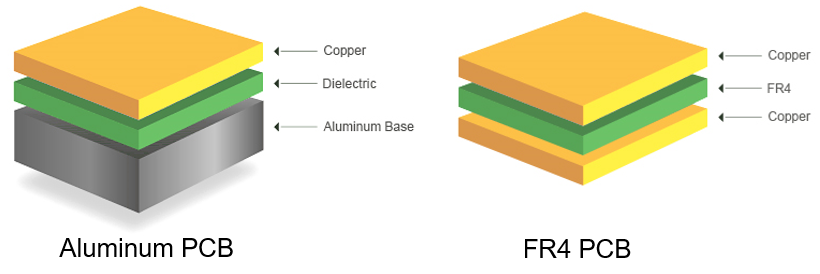

Aluminum PCBs have excellent thermal management properties, making them ideal for high-power and high-temperature applications. They use an aluminium base layer to effectively dissipate heat, ensuring components stay cool and operate reliably. This feature is especially valuable in LED lighting, power supplies, and automotive electronics, where heat dissipation is critical for longevity and performance. The construction of aluminium PCBs typically includes three layers: a copper circuit layer, a dielectric insulation layer, and an aluminium base layer. This structure effectively transfers heat away from heat-generating components, reducing the risk of overheating and failure. However, the specialized materials and manufacturing processes required for aluminum PCBs typically cost more than traditional FR4 PCBs.

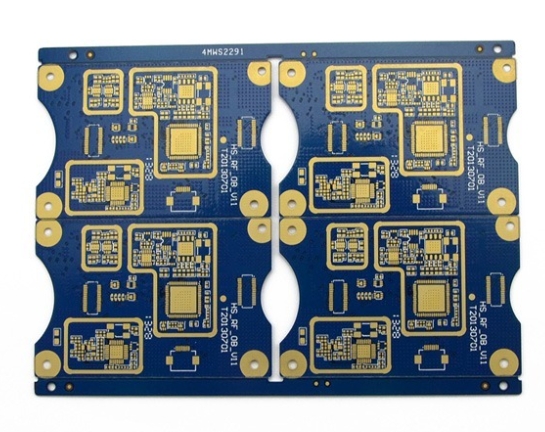

What Are FR4 PCBs?

FR4 PCBs are made of fibreglass-reinforced epoxy laminates, a material widely used in the PCB industry due to their excellent electrical insulation properties, mechanical strength, and cost-effectiveness. FR4 PCBs are versatile and can be used in various applications, from consumer electronics to industrial machinery. Their durability, ease of manufacturing, and relatively low cost are well-known. The well-established manufacturing process and readily available materials give them a cost advantage.

However, FR4 PCBs are less efficient than aluminium PCBs in thermal management, which can be a limiting factor in high-power or high-temperature environments.

Material Comparison of Aluminium PCBs vs. FR4 PCBs

When comparing the cost of aluminum PCBs and FR4 PCBs, one of the main factors is the material cost. Aluminum is a metal that is generally more expensive than the fibreglass and epoxy materials used in FR4 PCBs. In addition to the base material, the dielectric layers used in aluminium PCBs are generally more advanced and expensive than the epoxy used in FR4 PCBs. The dielectric layers in aluminum PCBs must effectively conduct heat away from the components, which requires higher quality and performance specifications. Therefore, the higher material cost of aluminium PCBs than FR4 PCBs leads to higher prices.

Price Comparison: Manufacturing Process

The manufacturing processes of aluminum PCBs and FR4 PCBs are also very different, affecting their respective prices. Aluminium PCBs require specialized equipment and processes to handle the metal substrate, including precise drilling, routing, and layer bonding techniques. These additional steps and the need for advanced machinery increase the production cost of aluminium PCBs. In contrast, manufacturers can achieve efficient large-scale production of FR4 PCBs through existing manufacturing infrastructure, thanks to its simpler and widely used process, thereby reducing costs. In addition, the materials used in FR4 PCBs are easier to use, further improving its cost and price advantages.

Making the Right Choice

When choosing between aluminum PCBs and FR4 PCBs, you need to consider the specific requirements of the application. Aluminum PCBs offer excellent thermal management capabilities, making them essential for high-power applications where heat dissipation is critical. Despite the higher cost, the performance benefits can justify the choice when overheating could lead to component failure and reduced reliability. FR4 PCBs, on the other hand, offer a more cost-effective solution. Their versatility, durability, and lower cost make them ideal for consumer electronics, industrial control systems, and general-purpose applications.

Ultimately

Due to factors such as material cost, manufacturing process, and performance characteristics, there is a big difference in the price of aluminum PCBs and FR4 PCBs. Aluminum PCBs have excellent thermal management performance and are more expensive, but provide key advantages for high-power applications. On the other hand, FR4 PCBs provide a cost-effective and versatile solution for a wide range of uses where thermal management is less important.