How does a 2-layer 10z PCB differ from a single-layer PCB?

Choosing a 2-layer 10z PCB or a single-layer PCB can significantly impact your electronic device’s performance, cost, and complexity. Understanding the differences between these two types of PCBs is critical to choosing the right option for your project. This blog post explores how 2-layer 10z PCBs differ from single-layer PCBs in design, performance, and applications.

2-layer 10z PCB vs. Single-layer PCB Design Complexity

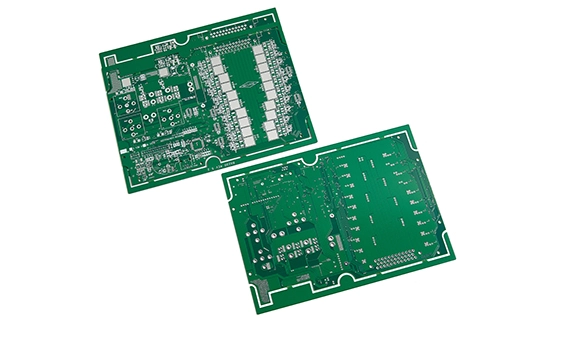

One key difference between 2-layer 10z and single-layer PCBs is their design complexity. Single-layer PCBs have one conductive layer, limiting component integration and circuit complexity. In contrast, 2-layer 10z PCBs have two layers of conductive material separated by an insulating layer. This two-layer configuration allows for more complex and compact designs because it provides additional routing options and space for components. The ability to route signals on both sides of the board significantly increases design flexibility and allows for more complex circuit layouts.

Thermal Management Performance of 2-layer 10z PCBs

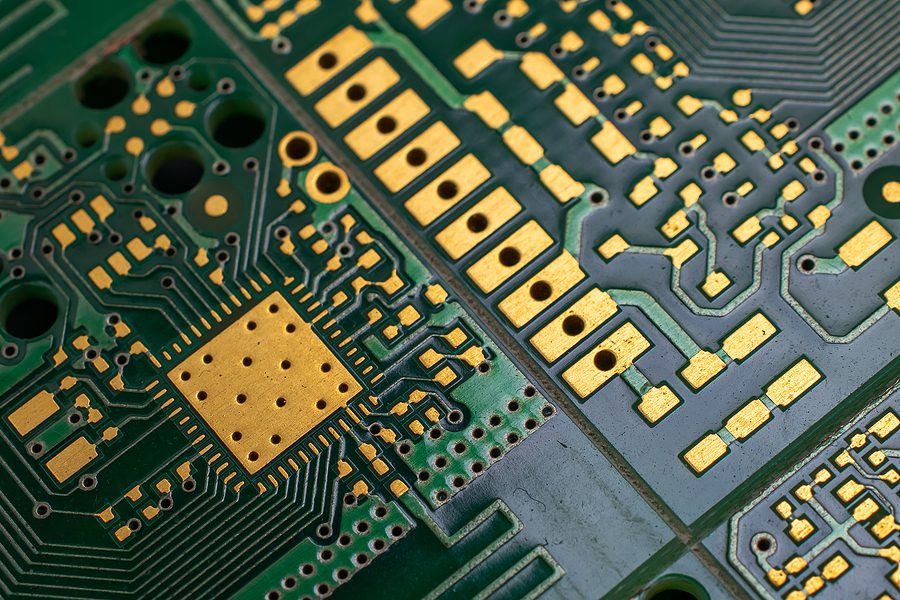

Thermal management is another critical area where 2-layer 10z PCBs outperform single-layer PCBs. The “10z” in 2-layer 10z PCBs refers to the thickness of the copper layer, typically 10 ounces per square foot. The increased copper thickness improves the ability to dissipate heat, making 2-layer 10z PCBs suitable for applications with high power requirements. Single-layer PCBs have thinner copper layers and can have issues dissipating heat, potentially leading to overheating and reduced reliability in high-power applications. The enhanced thermal management of 2-layer 10z PCBs helps improve the performance and lifespan of electronic devices.

Electrical Performance: Signal Integrity in 2-layer 10z PCBs

Signal integrity is a critical factor in PCB design, and the choice between 2-layer 10z PCBs and single-layer PCBs can impact electrical performance. 2-layer 10z PCBs offer better signal routing due to their dual-layer configuration, which reduces signal interference and crosstalk. This is particularly beneficial in high-speed and high-frequency applications where signal integrity is critical. Single-layer PCBs have limited routing options and can experience more signal attenuation and interference. 2-layer 10z PCBs offer dedicated ground and power planes, enhancing electrical performance and reducing noise.

Manufacturing and Cost Considerations

Both complexity and production processes must be considered when comparing the manufacturing and cost aspects of 2-layer 10z and single-layer PCBs. Due to their simple design, single-layer PCBs are generally more straightforward and cost-effective. In contrast, 2-layer 10z PCBs, with additional layers and thicker copper, involve more complex manufacturing and higher costs. However, the additional performance benefits and design flexibility of 2-layer 10z PCBs can justify the increased cost, especially for applications that require enhanced thermal management and signal integrity.

Application Suitability of 2-layer 10z PCBs vs. Single-layer PCBs

The suitability of 2-layer 10z PCBs vs. single-layer PCBs depends mainly on the intended application. Single-layer PCBs are often used in more straightforward, low-cost consumer electronics and devices with sufficient basic circuit functionality. On the other hand, 2-layer 10z PCBs are well suited for more demanding applications, such as high-power electronics, automotive systems, and high-frequency communications. The ability to handle higher power, provide better thermal management, and improve signal integrity makes 2-layer 10z PCBs the preferred choice for advanced, high-performance applications.

What are the advantages of 2-layer 10z PCBs

The design flexibility and integration capabilities of 2-layer 10z PCBs offer significant advantages over single-layer PCBs. The additional layers in 2-layer 10z PCBs allow for more complex circuit designs, including integrating additional components and features. This flexibility is precious in compact devices requiring limited space and more complex circuit layouts. Single-layer PCBs have limited space and routing options, may require more design compromises, and may limit the complexity of the final product.

Making the Right Choice Between the Two

2-layer 10z PCBs offer advantages in design complexity, thermal management, electrical performance, and application suitability. 2-layer 10z PCBs are more expensive, but their flexible performance is more advantageous for high-power and high-frequency applications.