How does Aluminum PCB enhance LED performance?

LED products’ performance and reliability largely depend on the technologies used in their design and manufacturing. Aluminum PCB is one of these key components. They are widely used in the LED industry to improve performance and lifespan due to their excellent thermal management properties and durability. In this guide, we will take a closer look at how aluminium PCBs can enhance LED performance.

Superior Thermal Management with Aluminum PCB

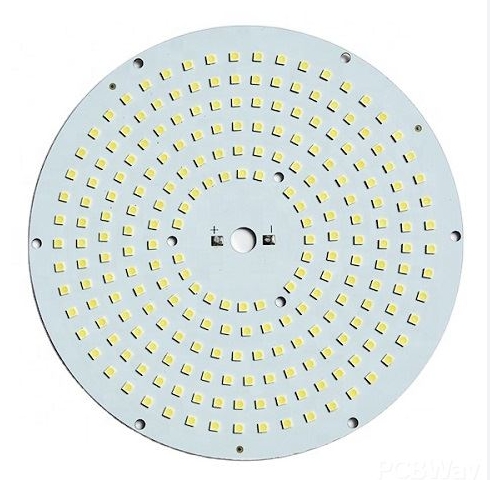

Thermal management is a key factor in LED performance and lifespan. LEDs generate a lot of heat during operation, which, if not managed properly, can lead to reduced efficiency, colour changes and shortened lifespan. Aluminium PCBs have excellent thermal conductivity and can effectively dissipate heat from LED components. The structure of aluminum PCBs usually comprises a thermal insulation layer, an aluminum base and a copper circuit layer to ensure efficient heat transfer. This reduces the thermal resistance between the LED and the heat sink, maintaining the optimal operating temperature and improving the performance and reliability of the LED. It also reduces heat build-up to prevent overheating, ensuring the LED remains bright and efficient for longer.

Improve the Durability and Lifespan of LEDs with Aluminum PCB

Durability is another important benefit of aluminium PCBs that can significantly improve the performance of LEDs. The sturdy construction of aluminium PCBs provides a solid foundation that can withstand mechanical stress and environmental factors. This is very important for some LED applications exposed to harsh conditions. The aluminium base of these PCBs provides excellent protection against physical damage and corrosion, ensuring the longevity of LED products. By providing a stable and durable platform, aluminium PCBs help maintain the structural integrity of LED components, reduce the possibility of failure and extend the overall life of LEDs.

Improved Electrical Performance

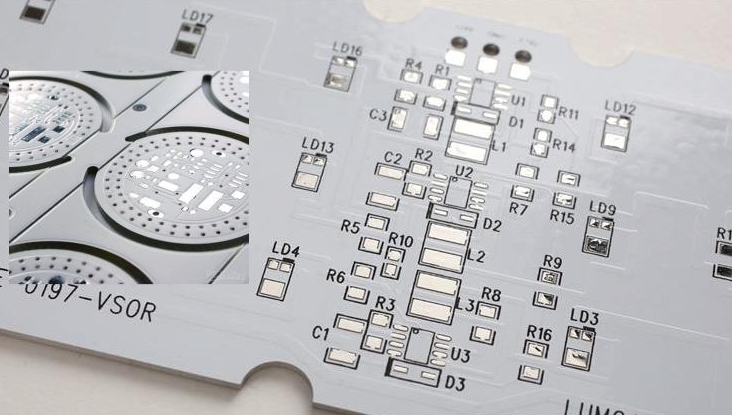

Aluminium PCBs not only excel in thermal management and durability, but they also improve the electrical performance of LEDs. Their copper circuit layers are designed to provide low resistance, ensuring efficient current flow to LED components. This efficient conductivity is essential to maintaining LED brightness and reducing power losses. In addition, their design flexibility allows for creating complex circuit patterns that optimize the electrical performance of LED systems. Manufacturers can customize PCB designs to meet specific performance requirements, ensuring LEDs operate at their best. By improving electrical efficiency, they help improve the energy efficiency of LED products.

Friendlier to the Environment Benefits

Sustainability is becoming increasingly important in the electronics industry, and aluminium PCBs contribute to this goal by providing multiple environmental benefits. In addition, the improved energy efficiency of LEDs using aluminium PCBs helps reduce energy consumption and greenhouse gas emissions. By improving the performance and lifespan of LEDs, aluminium PCBs support the development of environmentally friendly lighting solutions that meet global sustainable development goals. This environmental responsibility is an added advantage for manufacturers aiming to produce greener and more sustainable LED products.

Impact on LED performance

Aluminum PCBs improve LED products’ performance, durability, and efficiency. Thermal management, durability, and electrical performance make it an indispensable component in the LED manufacturing process. By leveraging the advantages of aluminium PCBs, LED manufacturers can produce high-quality, reliable, and cost-effective LED products.