How to increase the operating speed of SSD PCB?

In today’s digital age, SSDs have transformed data storage, offering faster speeds and reliability than traditional hard drives. At the heart of these drives is the SSD PCB, a critical component that determines the SSD’s role in performance. As the need for data access and processing increases, improving the speed of the SSD PCB becomes essential. This article will take a deep dive into various strategies and technical enhancements to improve SSD PCB performance.

1.Optimizing NAND Flash Interface

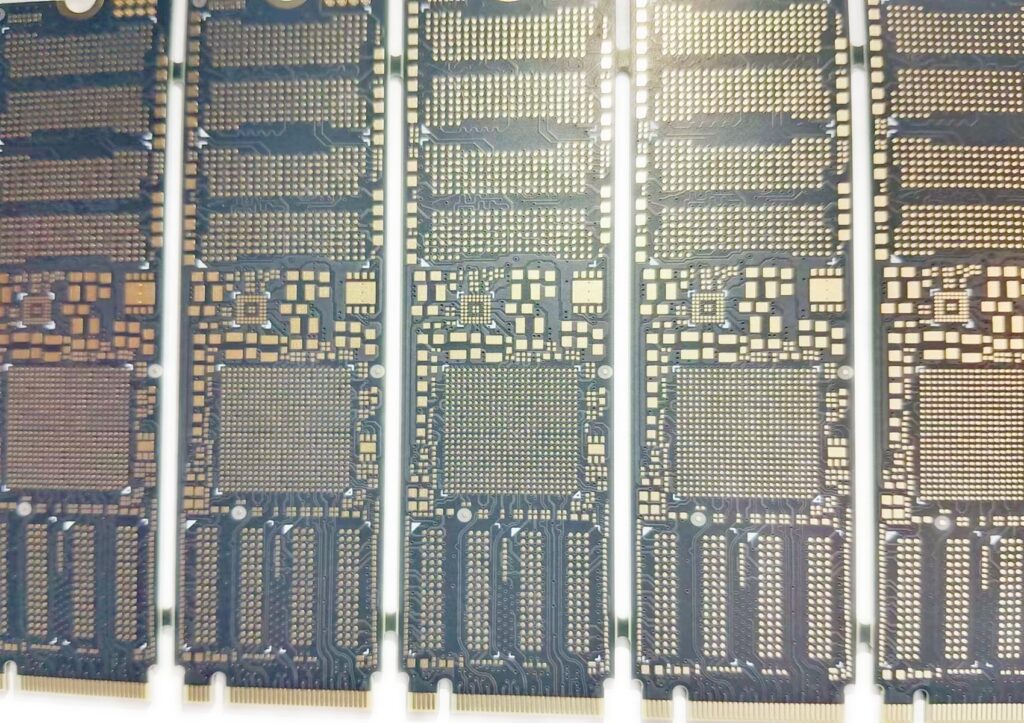

NAND flash is the storage medium in SSDs, and its interface with the PCB is a crucial determinant of speed. Improving speed requires selecting high-performance NAND flash chips and optimizing their arrangement on the SSD PCB. Using advanced types of NAND, such as 3D NAND or TLC (Triple Level Cell), and ensuring proper alignment and minimum distance between the memory chips and the controller can significantly increase data transfer rates. In addition, implementing a multi-channel architecture allows for parallel data processing, further increasing speed.

Increasing Controller Efficiency

The controller is the brain of the SSD, managing read and write operations and ensuring data integrity. An efficient controller can significantly improve SSD PCB speed. Therefore, we will choose a high-speed controller with advanced error correction and support for NVMe. Compared with traditional AHCI, the NVMe protocol provides lower latency and higher IOPS per second, making it a critical factor in improving speed.

2. Data path optimization in SSD PCB

Another way to improve SSD PCB speed is data path optimization. The data path is the path to transfer data from NAND flash to the controller and then to the host system. Optimizing this path involves minimizing signal loss and interference, which can reduce performance.

Reduce signal interference

Signal interference can be a significant bottleneck in achieving high speed. We will use advanced PCB design techniques such as differential signaling and proper trace routing to maintain signal integrity. Differential signaling involves using pairs of conductors to transmit the same signal in opposite phases, which helps eliminate noise and reduce electromagnetic interference (EMI).

Use high-quality materials

The choice of SSD PCB materials also affects its speed. High-quality, low-loss dielectric materials can reduce signal attenuation and improve overall performance. These materials help maintain signal strength over longer distances, ensuring data is transmitted quickly and reliably.

3. Power Management for SSD PCB Speed

Power management is another crucial aspect of SSD PCB design directly affecting speed. Efficient power management ensures that all components of the SSD operate optimally, reducing power consumption and heat generation, which can degrade performance.

Implementing Advanced Power Regulation

Advanced power regulation techniques help maintain consistent power for SSD components. We use LDOs and power management ICs (PMICs) to ensure that NAND flash memory and controllers receive stable power to prevent performance degradation due to power fluctuations. In addition, incorporating dynamic voltage and frequency scaling (DVFS) allows the SSD to adjust its power consumption based on the workload, thereby improving efficiency and speed.

Thermal Management

Heat is a byproduct of high-speed operation, and excessive heat can reduce performance and shorten the life of the SSD. By adopting effective thermal management strategies, such as using heat sinks, thermal pads, and active cooling solutions, you can help dissipate heat and maintain optimal operating temperatures. Keeping the SSD cool can reduce the risk of thermal throttling and ensure continued high-speed performance.

4. Advanced Techniques for SSD PCB Design

Implementing Multi-layer PCBs

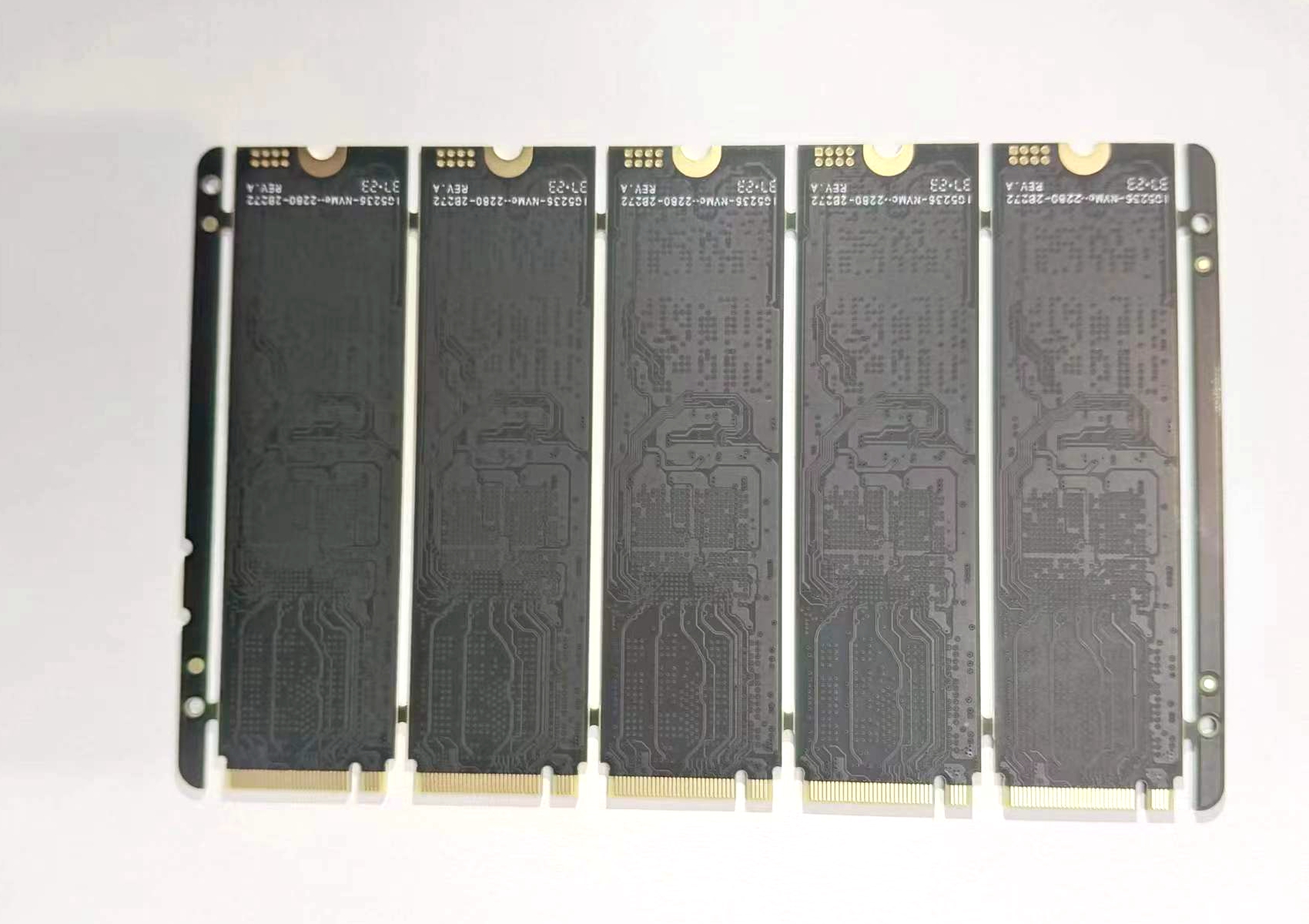

Multi-layer PCBs enable more complex routing and better signal integrity. By stacking multiple layers, designers can create more efficient data paths and reduce crosstalk between signals. This increases data transfer rates and improves overall performance. In addition, multi-layer PCBs can accommodate more components in a compact space, enabling the integration of additional features that increase speed.

Using High-speed Interfaces

High-speed interfaces such as PCIe and SATA are essential for high-speed data transfer. Choosing PCIe 4.0 or even PCIe 5.0 interfaces can provide higher bandwidth than older interfaces, resulting in faster data access and higher performance. Ensuring compatibility with these high-speed interfaces during the design phase can significantly increase speed.

Maximizing the Speed of SSD PCB

Increasing the speed of SSD PCBs requires a multifaceted approach, including optimizing the NAND flash interface, improving controller efficiency, effectively managing power, and employing advanced design techniques. Implementing these strategies enables our users to achieve significant performance gains and ensure that their SSDs run at peak speeds.