Is a 2 layer TG150 PCB suitable for LED applications?

PCBs are the foundation of modern electronic devices, providing essential structural frameworks and electrical connections for various applications. Among the many types of PCBs, 2 layer TG150 PCB are used by many due to their specific thermal and mechanical properties, but are they suitable for LED applications? This blog post aims to delve into this question and provide a comprehensive understanding for users and consumers who need 2 layer TG150 PCBs for LED applications.

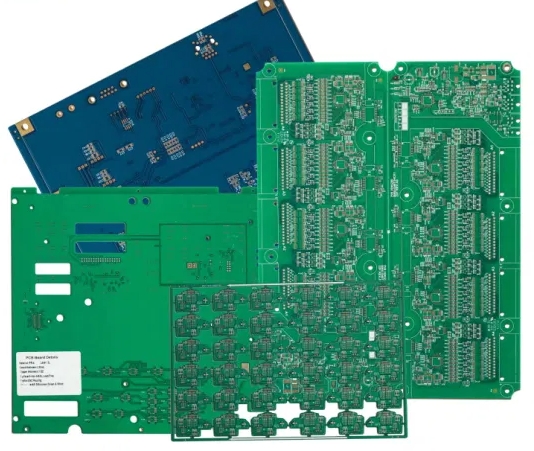

Basics of 2 layer TG150 PCBs

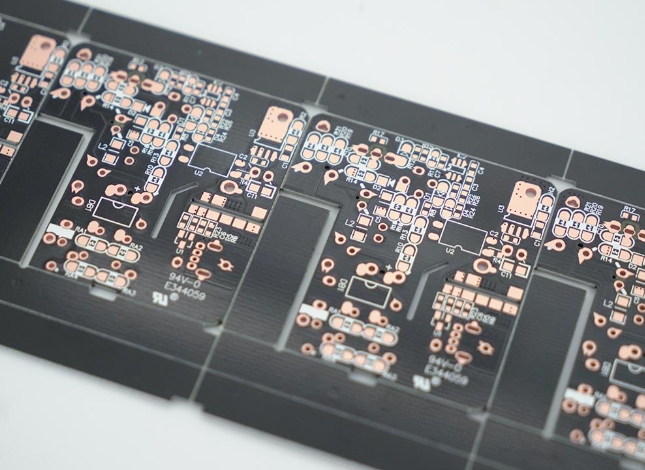

They comprise two conductive copper layers separated by an insulating substrate. This allows for more complex circuit designs compared to single-layer PCBs. The layers are interconnected by plated through holes (PTHs) or vias, which enable electrical connections between layers. A Tg of 150°C means that the PCB can operate reliably at temperatures up to 150°C without significant mechanical or electrical performance degradation. Higher Tg values improve thermal stability and durability, making TG150 PCBs suitable for demanding applications. The primary material used in TG150 PCBs is high-temperature epoxy reinforced with glass fabric, commonly known as FR-4. This material has excellent electrical insulation, mechanical strength, and heat resistance.

Key Factors That Make 2 Layer TG150 PCBs Suitable for LED Applications

The TG150 rating indicates that the PCB material can withstand temperatures up to 150°C before transitioning from a rigid state to a softer, more flexible state. This high glass transition temperature is critical for LED applications, which typically generate much heat during operation. The 2 layer TG150 PCB material helps to effectively dissipate heat and maintain the optimal operating temperature of the LED. Their double-layer design allows for better current distribution and heat dissipation, which is critical to maintaining the reliability and lifespan of LED circuits. The high-quality FR-4 material has consistent electrical properties, including low dielectric loss and high insulation resistance. These properties ensure stable and efficient electrical performance in LED circuits.

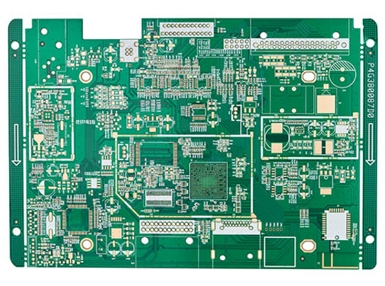

Electrical Performance and Reliability

In addition to thermal management, the electrical performance of a PCB is another critical factor. The 2 layer TG150 PCB has excellent electrical conductivity and insulation, essential for the stable operation of LED circuits. Compared to single-layer PCBs, the double-layer design allows for more complex circuits, helping to create more sophisticated and efficient LED drivers and control systems. In addition, the reliability of the TG150 material in high-temperature environments ensures consistent performance over time, reducing the risk of electrical failures that could impair LED functionality.

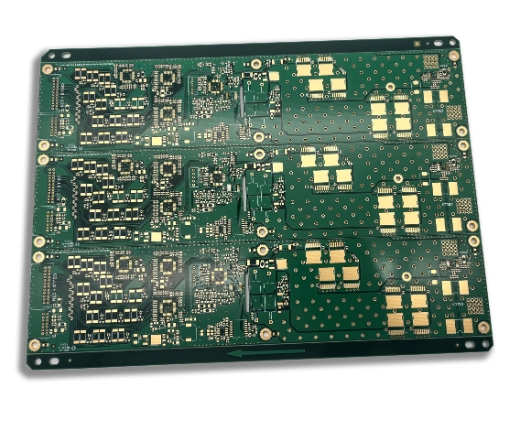

Mechanical Strength and Durability

LED applications often require PCBs that are not only thermally and electrically stable but also mechanically robust. The 2-layer TG150 PCB has enhanced mechanical strength due to its higher TG material. This means it can withstand mechanical stress better, making it more durable and less prone to cracking or warping under thermal cycling conditions. We manufacture using state-of-the-art processes that ensure precise layering and strong bonding between the copper layer and the FR-4 substrate. Using carefully drilled and copper-plated PTHs and vias ensures strong electrical and mechanical connections between layers. This helps improve the overall mechanical stability of the PCB, prevents delamination, and provides reliable performance, ensuring that the PCB maintains its integrity and performance over the long term.

Design Flexibility and Customization

Another advantage of using 2-layer TG150 PCBs in LED applications is their design flexibility. The two-layer configuration provides more room for routing complex circuits, allowing greater design customization to meet specific requirements. This flexibility is critical in LED applications, as different projects may have unique power, control, and layout needs. Whether designing a compact LED module for consumer electronics or a large panel for industrial lighting, a 2-layer TG150 PCB can be customized to various design specifications.

Ultimately

2-layer TG150 PCB is ideal for LED applications, offering excellent thermal management, electrical performance, mechanical strength, and design flexibility. 2-layer TG150 PCB is a rugged and versatile choice for users and consumers who want to integrate a reliable, efficient PCB into their LED projects.