M6 material PCB for wireless communication systems

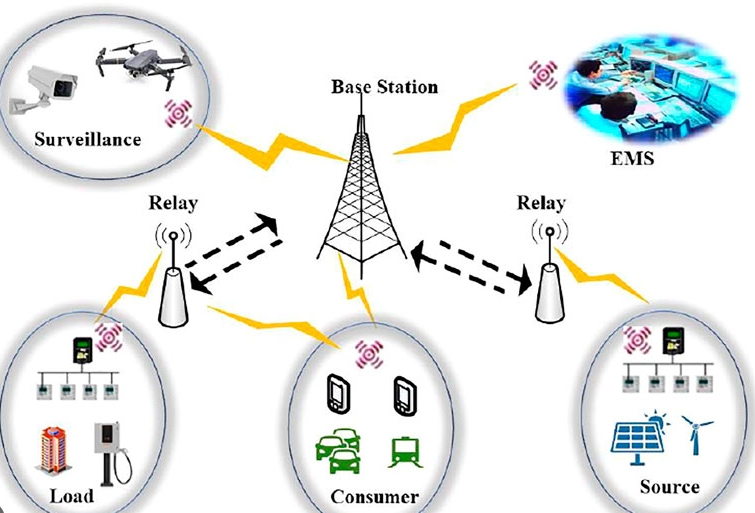

The demand for high-performance and reliable PCBs in wireless communication systems is increasing. M6 material PCB can change the wireless communication field and become the most suitable PCB for wireless communication systems. In this blog post, we look closer at the intricacies of M6 material PCBs and their critical role in optimizing wireless communications systems for superior functionality and efficiency.

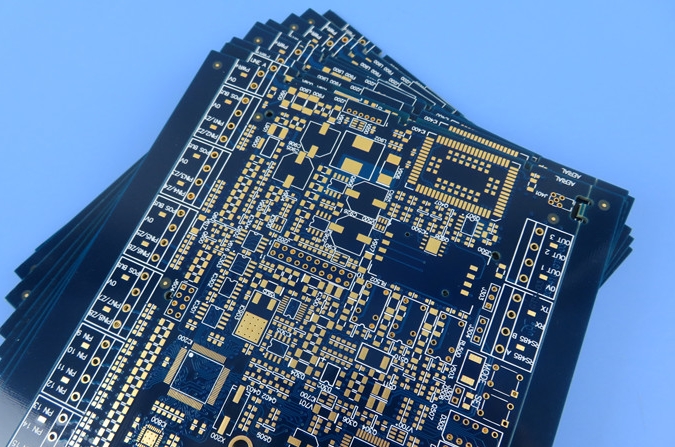

M6 material PCB: the basis of modern wireless communication systems

M6 material PCBs play a vital role as the foundation of modern wireless communication systems, providing necessary support for signal transmission and reception in various applications. Their high dielectric strength, low electrical losses, and sound insulation properties make them ideal for high-frequency applications such as wireless communication systems. Wireless communication systems, including cellular networks and Wi-Fi router devices, rely on M6 material PCBs to facilitate the transmission and reception of electromagnetic signals. These PCBs are platforms for mounting and interconnecting various electronic components, including RF transceivers, antennas, amplifiers, filters, and microcontrollers necessary for wireless communications functionality. The design and construction of PCBs with M6 material are optimized to minimize signal loss, interference, and impedance mismatch, ensuring reliable and efficient signal transmission in wireless communication systems.

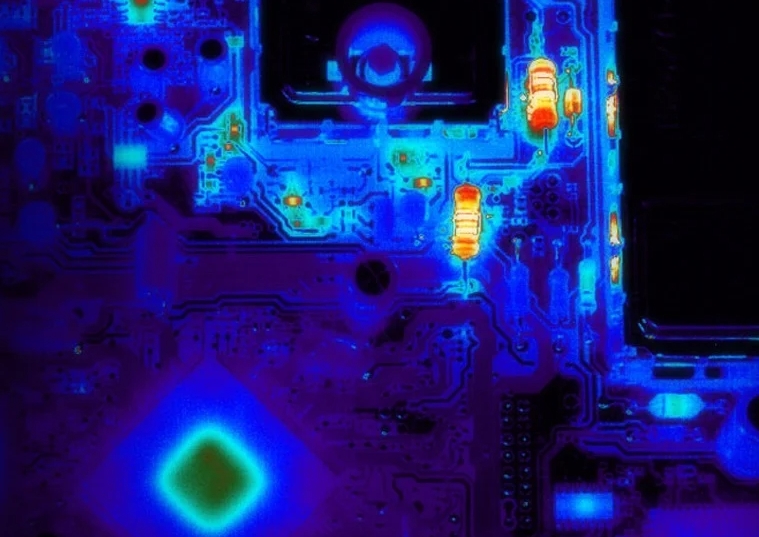

Enhanced thermal management: a key advantage of M6 material PCBs

Enhanced thermal management is a crucial benefit of M6 material PCBs, which provide several key benefits that help improve the performance, reliability, and longevity of electronic devices and systems. M6 material PCB has excellent thermal conductivity, allowing it to dissipate heat generated during operation effectively. This high thermal conductivity helps prevent the accumulation of local hot spots and thermal stress, which can degrade electronic component performance and lead to performance issues or premature failure. At the same time, their thermal conductivity effectively dissipates heat across the entire circuit board surface, ensuring even temperature distribution and reducing the risk of overheating critical components. By dissipating heat away from sensitive components, M6 material PCBs help maintain optimal operating temperatures and extend the life of electronic devices.

M6 Material PCB Optimizes Signal Integrity in Wireless Communication Systems

M6 material PCBs play a vital role in optimizing the signal integrity of wireless communication systems by minimizing signal loss and interference ensuring reliable and efficient transmission of electromagnetic signals. Their low dielectric loss properties help them reduce the attenuation of electromagnetic signals traveling through the circuit board. This property helps maintain signal strength and fidelity, ensuring signals remain intact and undistorted when transmitted in wireless communication systems. In addition, they enable optimized signal routing layouts, resulting in efficient signal propagation paths while minimizing crosstalk and interference. Careful placement and routing of signal traces, power planes, and ground planes can help minimize signal coupling and electromagnetic interference (EMI), ensuring clean and reliable signal transmission throughout the PCB.

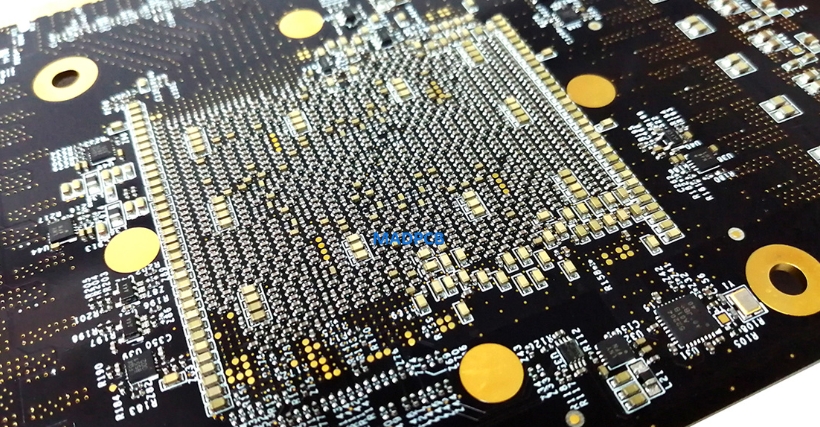

Flexibility and versatility meet the unique requirements of wireless communication systems

The flexibility and versatility of M6 material PCBs make them ideally suited to meet the unique requirements of wireless communications systems, and they support flexible multi-layer stacking configurations, allowing the integration of multiple signal, power, and ground layers. This flexibility also enables designers to optimize signal integrity, minimize crosstalk, and reduce electromagnetic interference (EMI), ensuring wireless communications systems’ reliable and efficient operation. As a result, compact and space-saving electronic device and system designs are enabled by providing high-density interconnect capabilities and efficient use of circuit board space. As a result, they can support fine-pitch components, tight traces, and small form factors, allowing the development of portable wireless communications devices without compromising performance or functionality.

Sturdy and reliable

Wireless communication systems often operate in challenging environments, and M6 material PCBs are designed to thrive in such conditions, providing rugged reliability and resilience to environmental stresses. Whether deployed in outdoor wireless networks, industrial IoT solutions, or mission-critical infrastructure, they ensure uninterrupted connectivity and operational stability in the harshest conditions.

Ultimately

M6 material PCBs represent a paradigm shift in wireless communications, delivering unparalleled performance, reliability, and versatility for modern connectivity solutions. So, by leveraging the M6 material’s superior thermal conductivity, signal integrity, and rugged reliability, it’s possible to take the functionality of wireless communications systems to new heights.