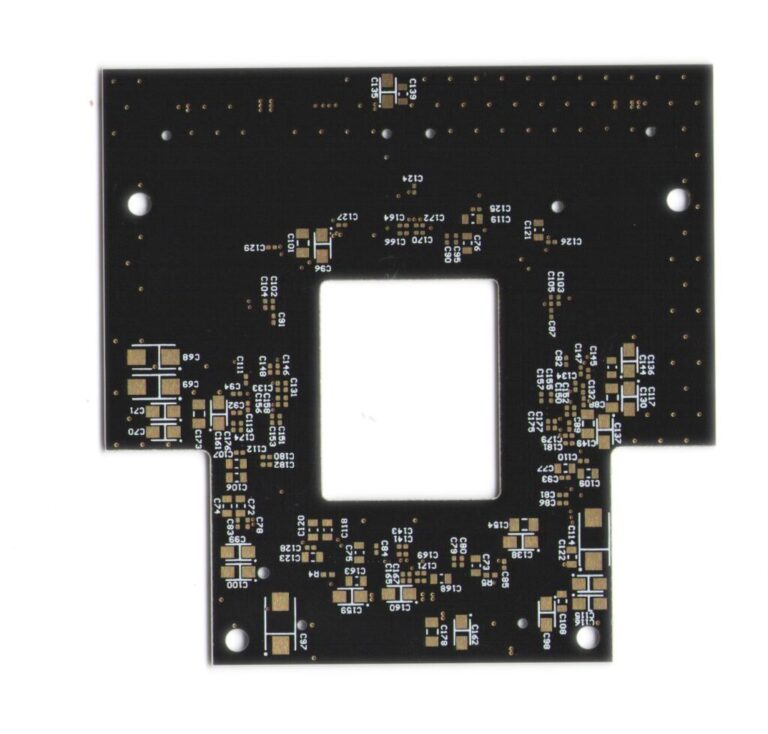

Ceramic PCB is a type of printed circuit board that uses ceramic materials as the substrate and has excellent thermal conductivity and insulation properties. Ceramic PCBs are printed circuit boards made of ceramic materials typically used in high-temperature, high-frequency, and high-power applications. The advantages of ceramic materials are their excellent thermal conductivity, electrical insulation, and mechanical stability, making them ideal for some particular fields.

The main parameters:

Materials: The main material of ceramic PCB is ceramic. Common ceramic materials include Alumina and Boron Nitride. Different materials have different properties and can be selected based on application needs.

Thickness: The PCB’s thickness depends on the ceramic substrate’s thickness, usually between 0.25mm and 2mm.

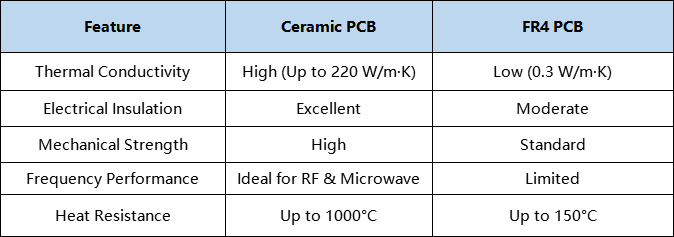

Thermal Conductivity: The thermal conductivity of ceramic PCB is one of its main advantages. Thermal conductivity is usually higher than other common PCB materials, helping to dissipate heat.

Electrical Insulation (Dielectric Strength): Ceramic PCB has excellent electrical insulation properties, making it suitable for high-voltage and high-frequency applications.

Surface Finish: The soldering surface of ceramic PCB usually needs to be coated with solder film to ensure soldering reliability.

If necessary, you can click to view more of our cases.

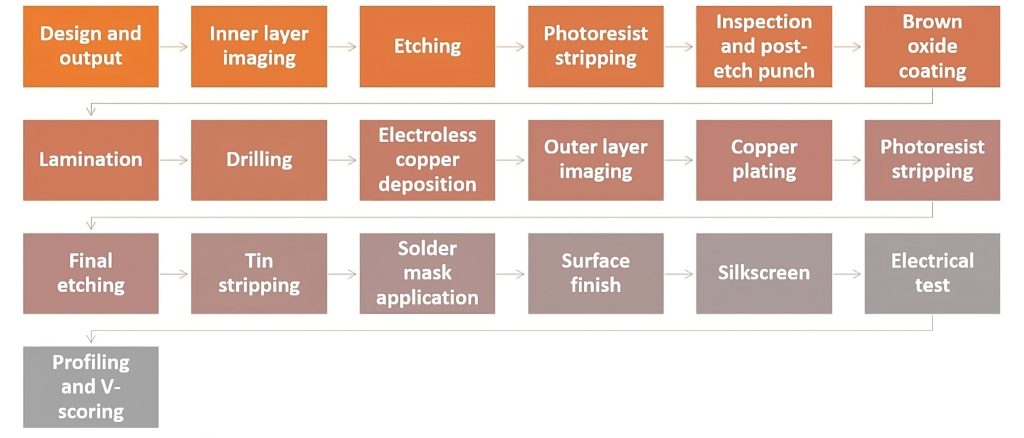

Manufacturing process:

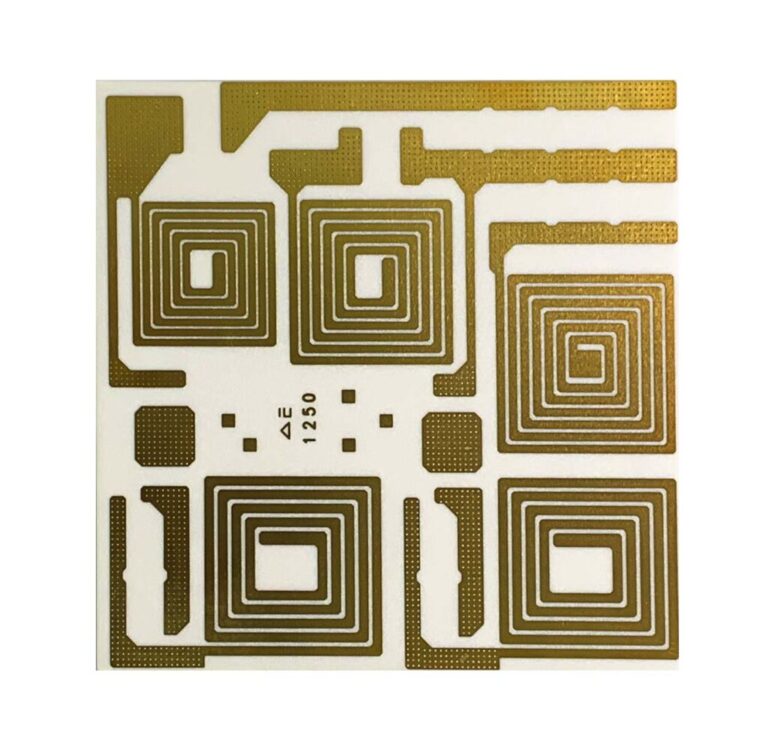

Material preparation: First, ceramic powder is prepared, and then the ceramic substrate is made through molding.

Insulating ceramic layer preparation: The ceramic layer is prepared on the substrate, usually through coating and sintering.

Conductive layer preparation: Copper foil or other conductive material is attached to the insulating ceramic to form a circuit.

Circuit chemical processing: Manufacturing circuits, including etching, additive plating, drilling, and other processes.

Soldering and Assembly: Mount the electronic components on the ceramic PCB and then solder them.

Quality Inspection: Ensure the quality and performance of ceramic PCBs through various tests and inspections.

Advantages of Heavy Copper PCB

✔ Superior Heat Dissipation: Thermal conductivity up to 170-220 W/m·K (AlN), far exceeding standard FR4 PCBs.

✔ High Electrical Insulation: Low dielectric constant and loss for optimal signal performance.

✔ Excellent Mechanical Strength: High resistance to wear, corrosion, and extreme temperatures.

✔ Direct Copper Bonding (DCB) & Low-Temperature Co-Fired Ceramic (LTCC) Options: Advanced fabrication methods for enhanced reliability.

Heavy Copper PCB VS. Standard PCB

Why Choose Us

Competitive Pricing

More than a decade of experience in the PCB industry ensures quality components at competitive prices.

Fast and reliable delivery

Partnership with multiple global logistics providers ensures timely and reliable shipping.

Quality Assurance

A dedicated quality control team conducts manual visual inspections to ensure all products meet strict quality standards.

We have many international certifications:

We also hold several international quality certifications:

●IATF 16949:2016

●ISO 9001:2015

●ISO 45001:2018

●UL

At the same time, we are always committed to environmental protection. We have an environmental management system certification to ensure that our manufacturing process is environmentally friendly and sustainable.

Frequently Asked Questions(FAQ)

- What ceramic materials do you offer?

We manufacture Ceramic PCBs using Aluminum Oxide (Al₂O₃), Aluminum Nitride (AlN), and Silicon Nitride (Si₃N₄).

- Are ceramic PCBs suitable for multilayer designs?

Yes! We provide multilayer ceramic PCBs using HTCC and LTCC technologies for complex applications.

- How can I get a quote for Ceramic PCBs?

Contact us with your specifications, and we’ll provide a quote within 24 hours.