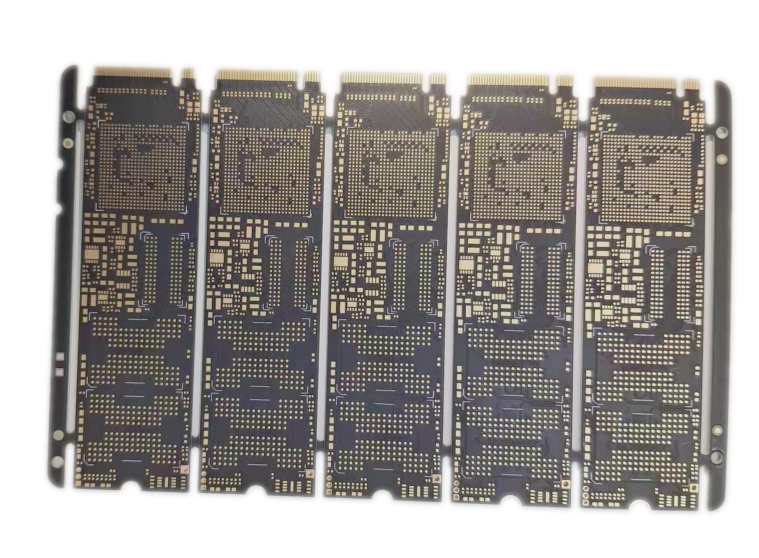

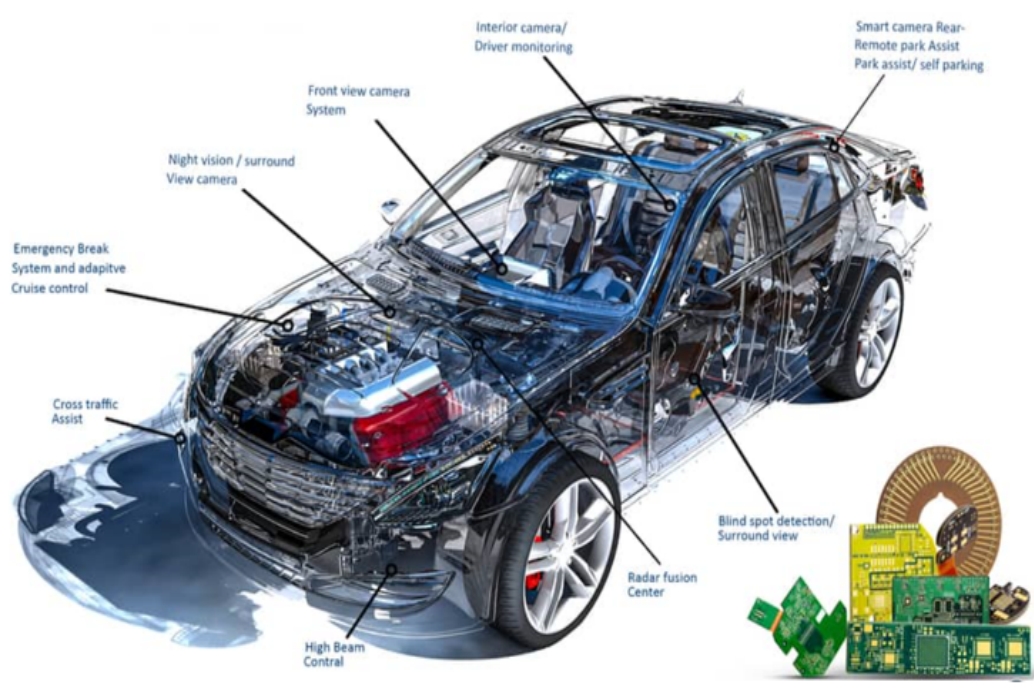

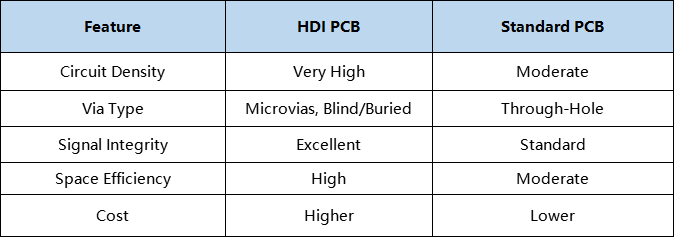

HDI PCB is a multi-layer circuit board with high wiring density, thin lines, spaces and micro-holes. They are designed to increase the functionality and performance of electronic products while reducing their size. High-Density Interconnect (HDI) PCBs represent technological advancements in printed circuit board design and manufacturing. These boards are known for their enhanced electrical performance and compact size.

Parameters and features:

Number of layers: HDI PCBs typically have more than two layers. Standard configurations include 4-layer, 6-layer, 8-layer, and up to 20 or more layers.

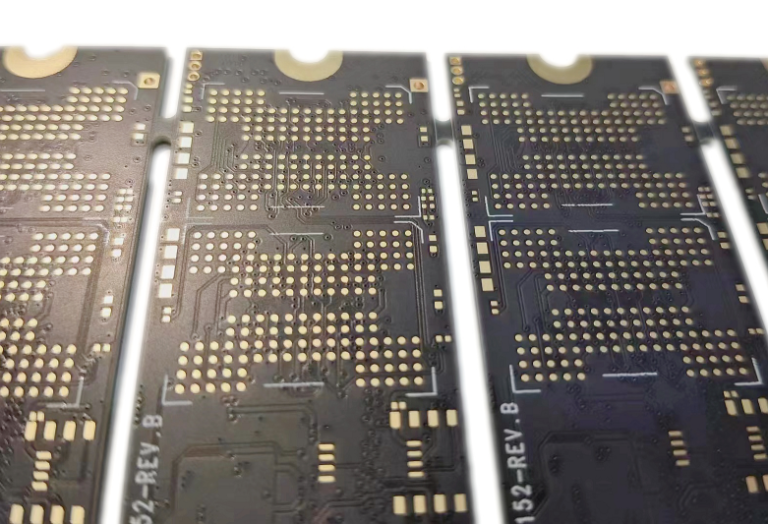

Microvias: Microvias are small, laser-drilled holes connecting different PCB layers, allowing for higher routing density.

Thin Lines/Spaces: HDI boards have narrow traces and gaps, usually measured in microns (μm). This allows for a more compact design.

Advanced Materials: HDI PCBs use advanced materials such as high-frequency laminates for optimal signal integrity and impedance control.

Aspect Ratio: Aspect ratio is the ratio of PCB thickness to microvia diameter. HDI boards usually have a high aspect ratio.

Blind and Buried Vias: These types of vias begin or end on inner layers, enhancing routing possibilities.

Via-in-Pad (VIP): This design places the via within the component bonding pad, allowing the use of smaller component sizes.

If necessary, you can click to view more of our cases.

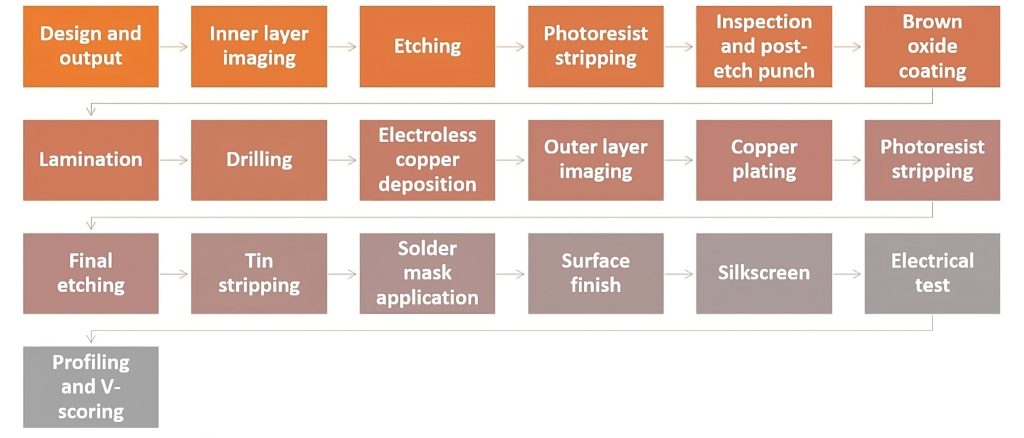

Manufacturing process:

Lamination begins with heat and pressure to layer and bond thin core materials to create a multi-layer stack.

Drilling: Laser drilling and mechanical drilling can create micro vias and vias.

Copper Plating: After drilling, copper is deposited on the hole’s walls to create a conductive path.

Imaging: The photolithography process uses a layer of photoresist and ultraviolet light to define circuit patterns on each layer.

Etching: Chemically removing exposed copper, leaving the desired copper traces.

Copper Fill and Planarization: In the case of buried vias, any excess copper is filled and then planarized to create a flat surface.

Solder mask and screen printing: Solder mask insulates and protects copper traces, while screen printing adds component labels.

Surface Treatment: The PCB’s surface undergoes surface treatment, such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling).

Advantages of Heavy Copper PCB

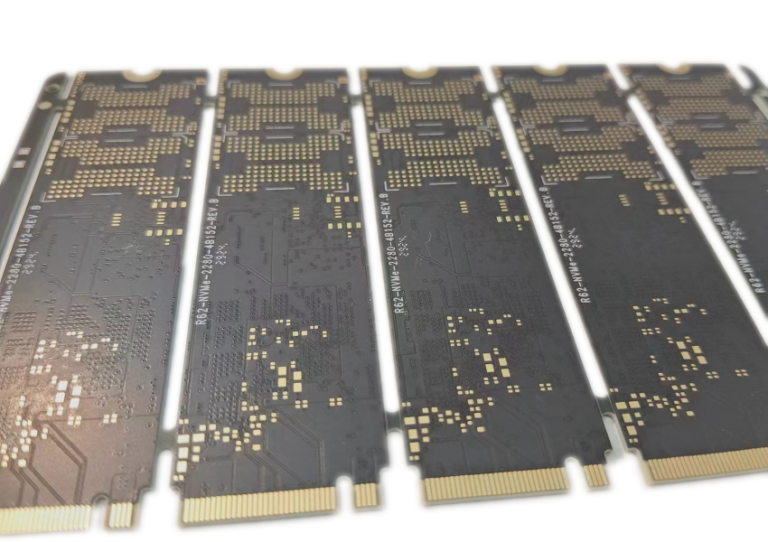

✔ High-Speed Data Processing: Supports NVMe, PCIe, and SATA interfaces for optimal performance.

✔ Advanced Thermal Management: Utilizes copper layers and thermal vias for effective heat dissipation.

✔ Compact & Lightweight Design: Enables ultra-thin and high-density storage solutions.

✔ Customizable Form Factors: Tailored for M.2, U.2, and 2.5-inch SSD designs.

SSD PCB VS. HDD PCB

Why choose us:

Competitive Pricing: With more than a decade of experience in the PCB industry, we have established a reliable supply chain that ensures quality components at competitive prices. For complex projects requiring unique materials or advanced technical specifications, our strong manufacturing capabilities enable us to provide cost-effective solutions while maintaining high quality.

Fast and reliable delivery: We ensure fast production and delivery. Our partnership with multiple global logistics providers guarantees timely and reliable transportation, supported by our digital factory management and 90% automation for greater efficiency.

Quality Assurance: Our rigorous quality inspection begins with incoming material checks. We use AOI to detect defects and X-rays to identify internal issues. Electrical performance testing is performed with advanced automatic test machines and flying probe testers. Before shipment, our dedicated QC team conducts a thorough manual visual inspection to ensure all products meet strict quality standards.

We have many international certifications:

We also hold several international quality certifications:

●IATF 16949:2016

●ISO 9001:2015

●ISO 45001:2018

●UL

At the same time, we are always committed to environmental protection. We have an environmental management system certification to ensure that our manufacturing process is environmentally friendly and sustainable.

Frequently Asked Questions(FAQ)

- What HDI stack-ups do you offer?

We manufacture 1+N+1, 2+N+2, 3+N+3, and Any-Layer HDI PCBs.

- Can you provide impedance-controlled HDI PCBs?

Yes! We offer custom impedance control designs for high-speed applications.

- How can I get a quote for HDI PCBs?

Contact us with your design files, and we will provide a quote within 24 hours.