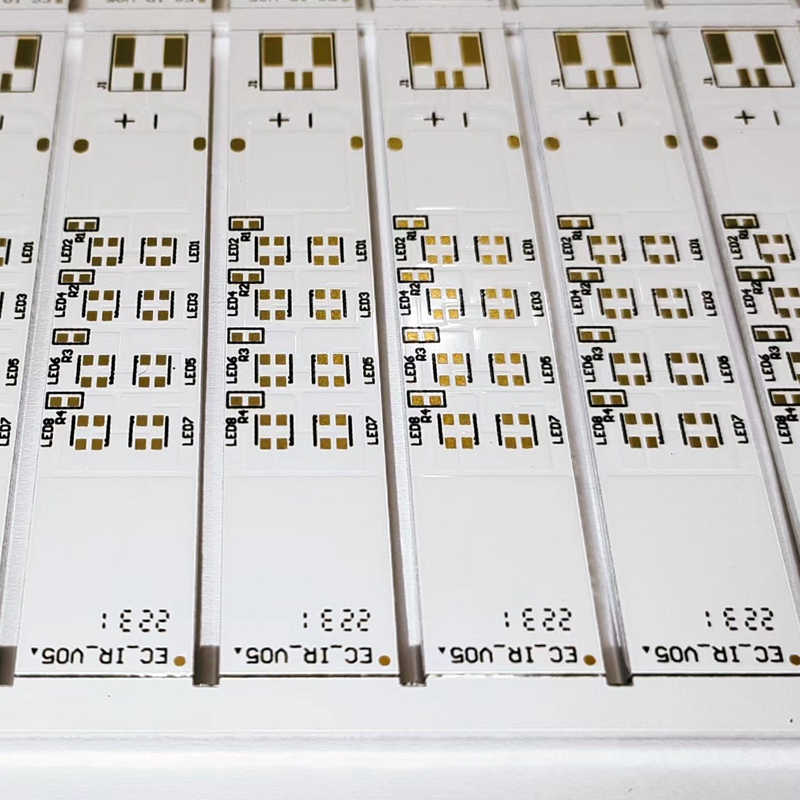

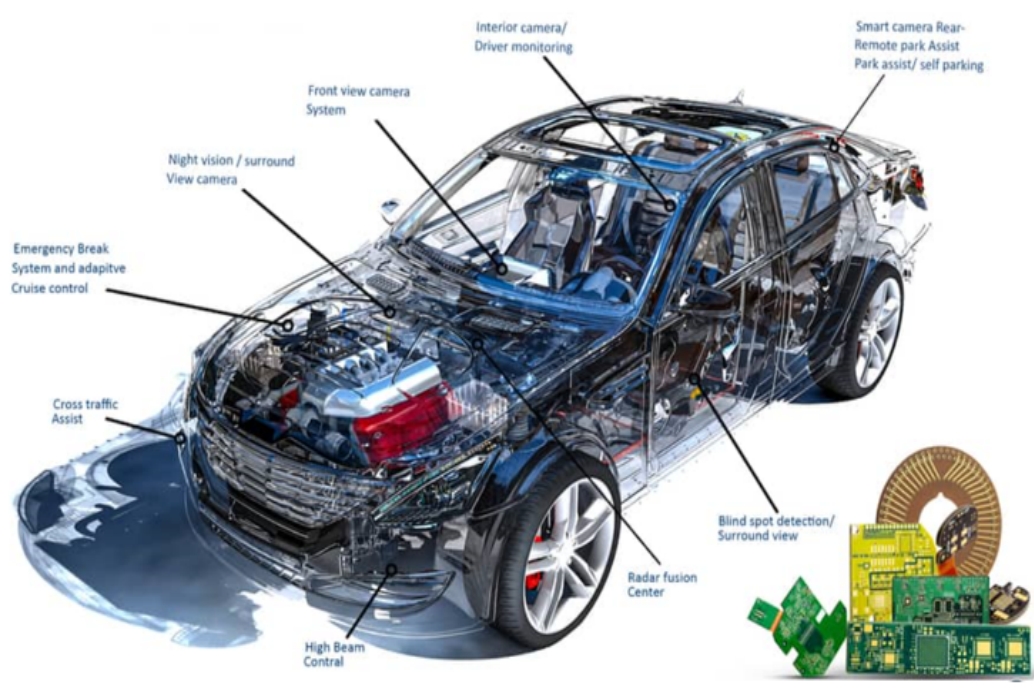

Metal Substrate PCB is a special printed circuit board that uses a metal substrate as the circuit board base material. They are often used in applications requiring high heat dissipation and electrothermal performance, such as LED lighting, power modules, automotive electronics, wireless communications, and other high-power electronic equipment.

Related parameters:

Metal substrate: Metal substrate is usually made of aluminum or copper and has excellent heat dissipation properties. Aluminum substrates are widely used in applications with high lightweight requirements, while copper substrates are suitable for applications that require higher thermal conductivity.

Insulating layer: The top layer of a metal substrate usually has a layer of insulating material, such as electronic grade insulating resin (Dielectric Material), to isolate the circuit layer and the metal substrate to prevent short circuits.

Circuit layer: The circuit layer of the metal substrate is located above the insulating layer and is a key part of the printed circuit board, on which electronic components and wires are arranged.

Copper foil thickness: Copper foil in circuit layers usually comes in different thicknesses, common thicknesses include 1oz (ounces) and 2oz. Thick copper foil can be used to provide better electrical performance and heat dissipation.

Insulation layer thickness: The thickness of the insulation layer typically ranges from tens to hundreds of microns, depending on the needs of the specific application.

Soldering pads: There are usually solder pads on metal substrates used to connect circuit boards and other electronic components, such as LEDs, heat sinks, etc.

Size and Shape: The size and shape of metal substrates vary by application and can be customized based on design requirements.

If necessary, you can click to view more of our cases.

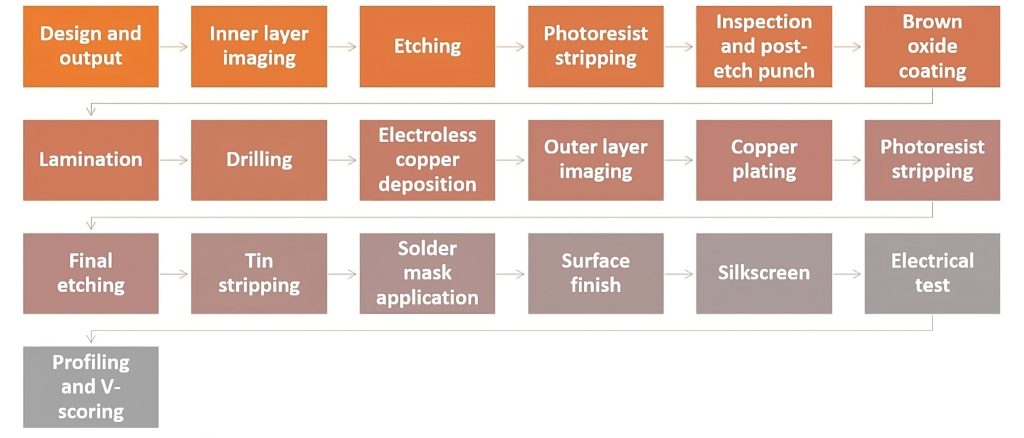

Manufacturing process:

Substrate preparation: Select a metal substrate of the appropriate type and thickness, clean it, and prepare it on the surface.

Insulating coating: Coating a metal substrate with an insulating material, usually electronic-grade insulating resin. The insulation layer isolates the circuit layer from the metal substrate.

Copper Foil Bonding: Bonding of copper foil over an insulating layer. A circuit pattern will be formed on the copper foil.

Circuit Board Fabrication: Using printing and etching processes to create patterns for circuit boards. This involves stripping away the required circuit layers and removing unwanted copper foil by etching.

Pad Processing: Processing of solder pads to connect metal substrate PCBs to other electronic components.

Testing and Inspection: Testing and quality inspection of metal substrate PCBs to ensure circuit performance and reliability.

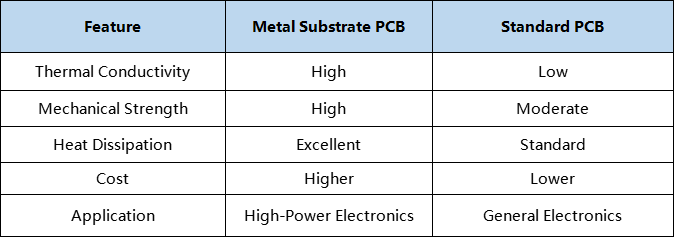

Advantages of Metal Substrate

✔ Superior Heat Dissipation: Transfers heat away from components, preventing overheating.

✔ High Mechanical Strength: More durable than standard FR4 PCBs.

✔ Improved Electrical Performance: Reduces thermal expansion, improving reliability.

✔ Enhanced Thermal Conductivity: Ideal for high-power applications.

✔ Cost-Effective: Reduces the need for additional cooling solutions.

Metal Substrate VS. Standard PCB

Why choose us:

Competitive Pricing: With more than a decade of experience in the PCB industry, we have established a reliable supply chain that ensures quality components at competitive prices. For complex projects requiring unique materials or advanced technical specifications, our strong manufacturing capabilities enable us to provide cost-effective solutions while maintaining high quality.

Fast and reliable delivery: We ensure fast production and delivery. Our partnership with multiple global logistics providers guarantees timely and reliable transportation, supported by our digital factory management and 90% automation for greater efficiency.

Quality Assurance: Our rigorous quality inspection begins with incoming material checks. We use AOI to detect defects and X-rays to identify internal issues. Electrical performance testing is performed with advanced automatic test machines and flying probe testers. Before shipment, our dedicated QC team conducts a thorough manual visual inspection to ensure all products meet strict quality standards.

We have many international certifications:

We also hold several international quality certifications:

●IATF 16949:2016

●ISO 9001:2015

●ISO 45001:2018

●UL

At the same time, we are always committed to environmental protection. We have an environmental management system certification to ensure that our manufacturing process is environmentally friendly and sustainable.

Frequently Asked Questions(FAQ)

- What metal core materials do you offer for MCPCBs?

We provide aluminum, copper, and stainless steel cores depending on thermal and mechanical requirements.

- Can you manufacture multi-layer Metal Core PCBs?

Yes! We offer multi-layer MCPCBs for advanced thermal management applications.

- How can I get a quote for Metal Substrate PCBs?

Simply contact us with your design files, and we will provide a quote within 24 hours.