SSD PCB is a type of printed circuit board designed specifically for use in solid-state drives, utilizing advanced materials and technologies to support high-speed data storage. These PCBs are typically used in consumer electronics, enterprise storage systems, and high-performance computing applications. The key benefits of SSD PCBs are their ability to efficiently manage data transfer, integrate flash memory chips, and ensure durability, making them an essential component in modern data storage solutions.

Key Parameters:

Copper Thickness: Typically, copper thickness ranges from 1 ounce to 3 ounces.

Dielectric Material: Typically FR4 or high-frequency laminated insulating copper layer.

Line Width and Distribution: Narrower lines are used for high-speed signals, while wider lines are used for power transmission.

Via Size and Plating: The size of the via and the quality of the copper plating are critical to signal reliability and the overall performance of the SSD.

Thermal Management: SSD PCBs may include thermal vias and deep or embedded copper planes to remove heat generated by memory chips, controllers, and other components.

Surface Finish: Common surface finishes include ENIG (electroless nickel immersion gold), HASL (hot air solder leveling), and OSP (organic solderability preservative).

Impedance Control: PCB design must control the impedance of traces, significantly differential pairs used in data signals, to ensure accurate data transmission without reflections or losses.

Component Placement and Kitting: The placement of components, including chips, controllers, and connectors, must be optimized for signal routing and power distribution.

Electrical testing and reliability: The SSD PCB undergoes rigorous electrical testing to ensure that all signal, power, and data transfer paths function correctly.

If necessary, you can click to view more of our cases.

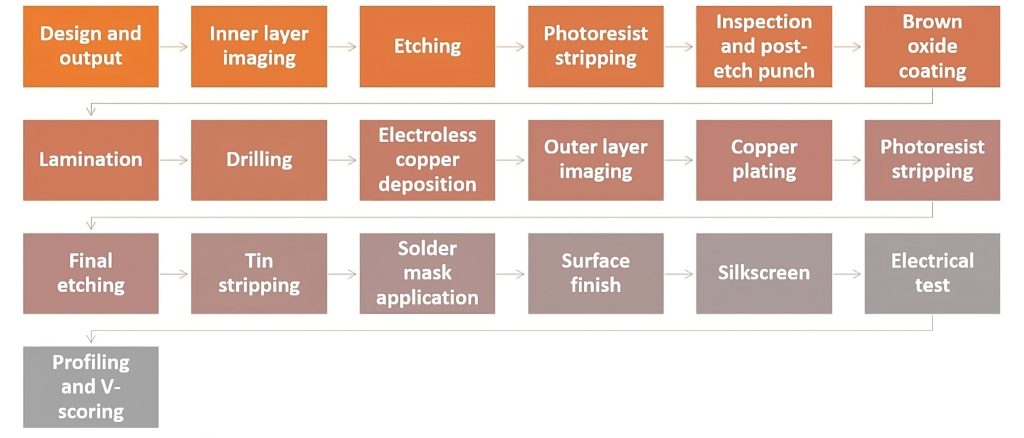

Manufacturing Process:

Layering: The base material is layered with copper foils on both sides, forming the foundation of the SSD PCB.

Circuit Design: The SSD PCB layout ensures proper trace widths and spacing for high-speed data transfer and power delivery.

Laminating: The copper and dielectric layers are bonded under heat and pressure to form a solid PCB.

Drilling: Precision drilling creates holes for vias and components.

Copper Plating: Copper is electroplated to build up the copper traces and vias to the required thickness.

Etching: Excess copper is removed, leaving the designed circuit traces.

Solder Mask Application: A solder mask protects the copper traces and exposes only the areas where components will be soldered.

Silkscreen Printing: Component labels and other markings are printed on the surface of the PCB.

Surface Finish: A surface finish, such as ENIG or HASL, is applied to protect the copper and improve solderability.

Testing and Inspection: The final PCB is tested for electrical integrity and inspected for quality.

Advantages of SSD PCB PCB

✔ Consumer Electronics: Smartphones, tablets, and smartwatches.

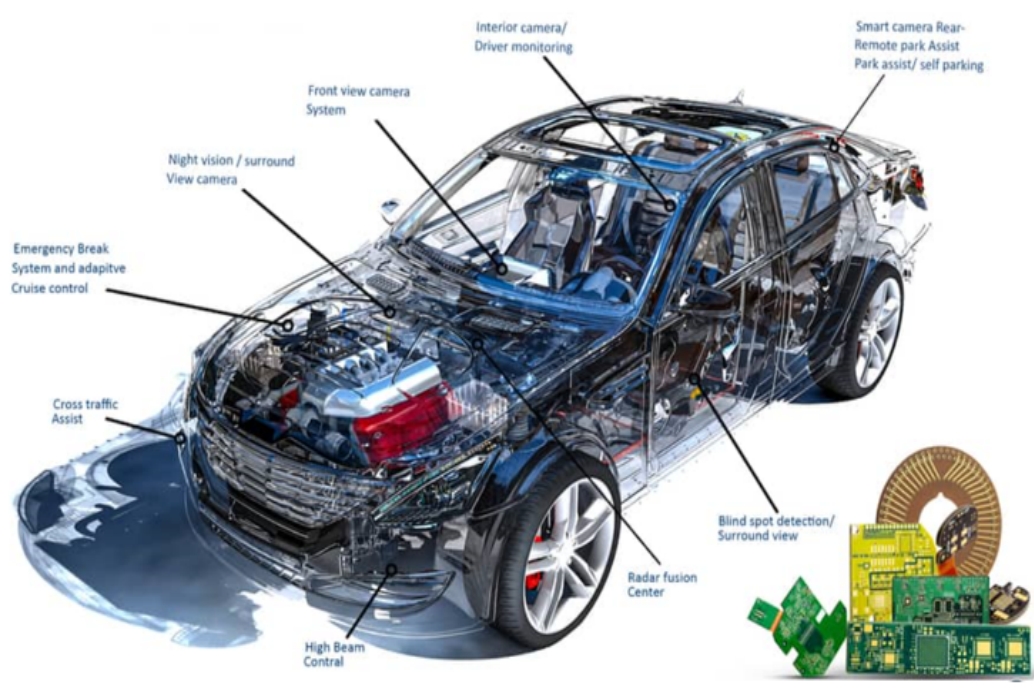

✔ Automotive Electronics: Advanced driver-assistance systems (ADAS), sensors, and infotainment.

✔ Medical Devices: Wearable health monitors, imaging systems, and diagnostic tools.

✔ Aerospace & Defense: Satellite systems, avionics, and military-grade equipment.

✔ Telecommunications: 5G base stations, network hardware, and RF devices.

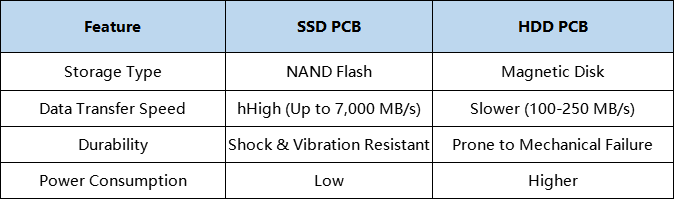

SSD PCB VS. HDD PCB

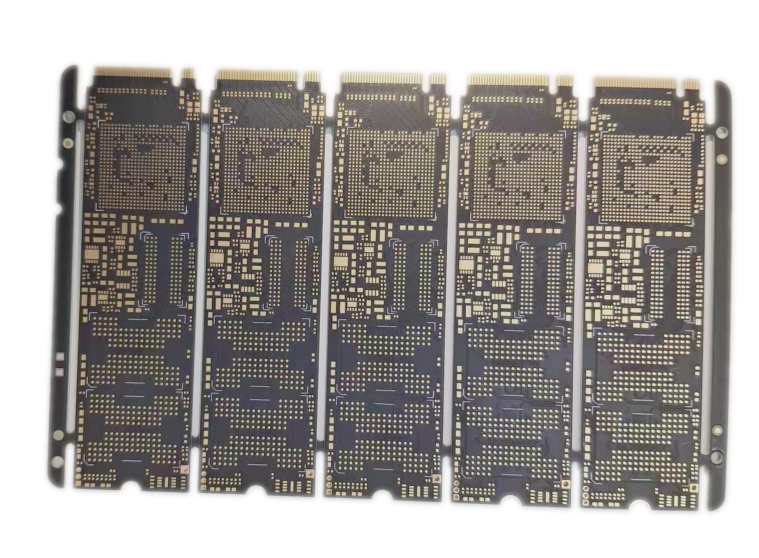

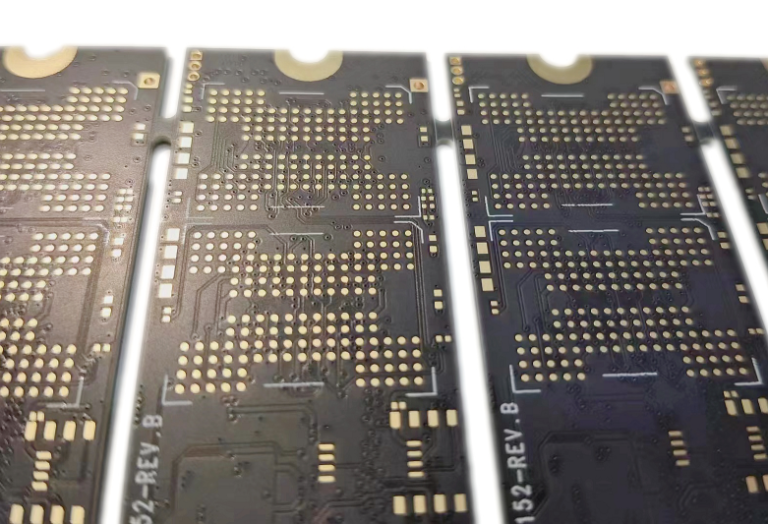

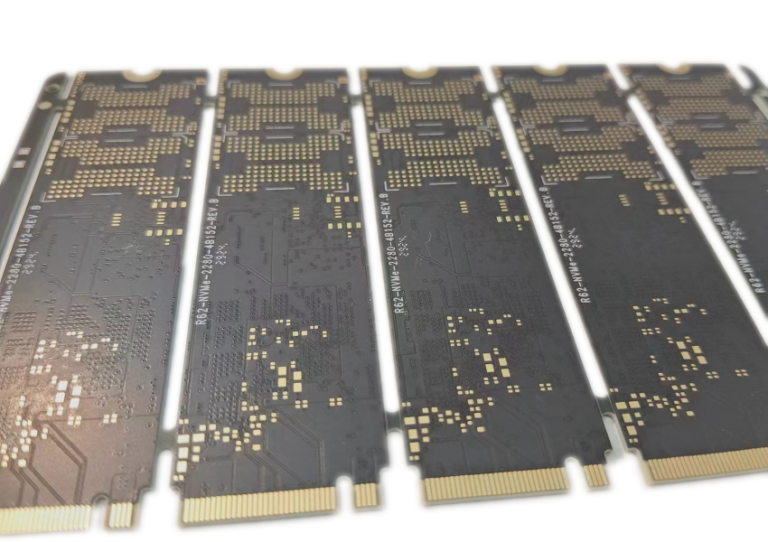

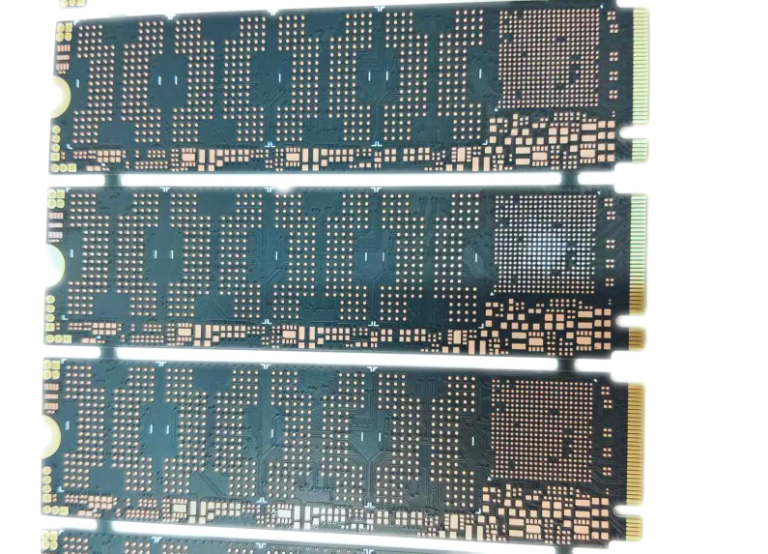

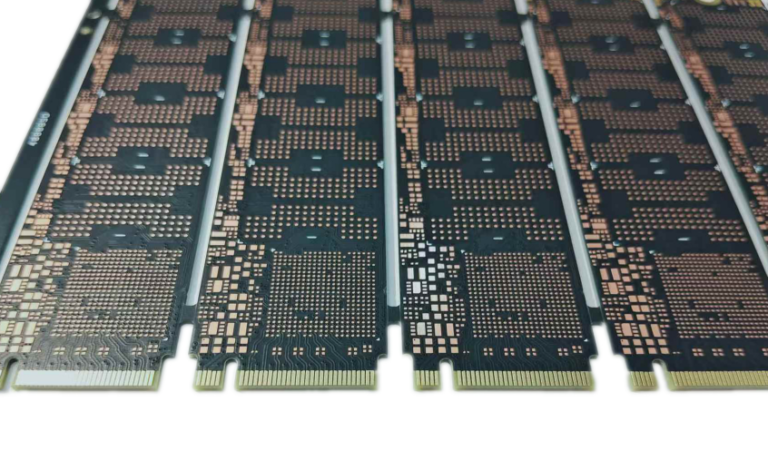

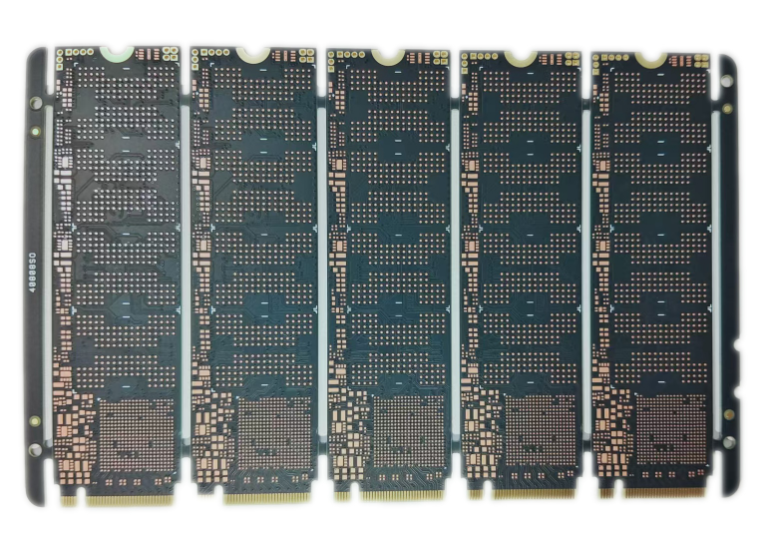

Our SSD PCB Case

8 Layer SSD PCB

Layer Count: 8 Layer

Material: FR4 TG170

Board Thickness: 0.85mm +/-0.05mm

Min Trace 3/3mil

Min BGA 8mil

Min Hole 0.15mm

Surface Treatment Immersion Gold 2u’

Board Size 22mm*80mm

Panel Size 126mm*80mm/5pcs

Solder Mask Matte Black

Other Specs R72DL-NVMe-2280-4B152

Interface: M.2 interface

Protocol NVMe

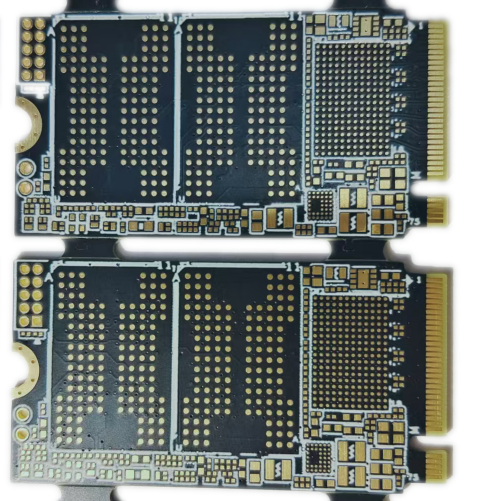

High Speed SSD PCB

Layer Count: 8 Layer

Material: FR4 TG170

Board Thickness: 0.85mm +/-0.05mm

Min Trace 3/3mil

Min BGA 8mil

Min Hole 0.15mm

Surface Treatment Immersion Gold 2u’

Board Size 22mm*42mm

Panel Size 134mm*86mm/10pcs

Solder Mask Matte Black

Other Specs IG5220-ON1000B-V1.0

Interface: M.2 interface

Protocol NVMe

Why Choose Us

Competitive Pricing

More than a decade of experience in the PCB industry ensures quality components at competitive prices.

Fast and reliable delivery

Partnership with multiple global logistics providers ensures timely and reliable shipping.

Quality Assurance

A dedicated quality control team conducts manual visual inspections to ensure all products meet strict quality standards.

We Have Many International Certifications

We also hold several international quality certifications:

●IATF 16949:2016

●ISO 9001:2015

●ISO 45001:2018

●UL

At the same time, we are always committed to environmental protection. We have an environmental management system certification to ensure that our manufacturing process is environmentally friendly and sustainable.

Frequently Asked Questions(FAQ)

- What is the maximum bend radius for your FPC PCBs?

Our FPC PCBs can be designed with a bend radius as low as 1mm, depending on material and layer count.

- Can you manufacture rigid-flex PCBs combining FPC and rigid layers?

Yes! We offer rigid-flex PCB manufacturing for hybrid designs requiring both flexibility and structural support.

- How can I request a quote for FPC PCBs?

Contact us with your design files, and we will provide a quote within 24 hours.