The Role of Automotive PCB in Advanced Driver Assistance Systems

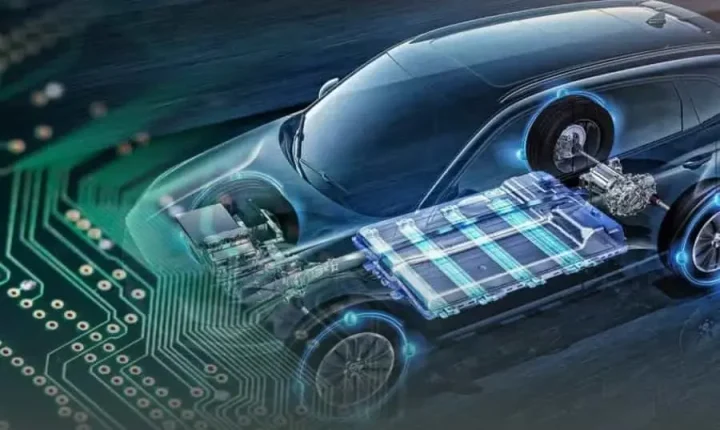

Advanced Driver Assistance Systems are revolutionizing modern vehicles. These systems rely heavily on high-performance Automotive PCBs to function seamlessly. From collision avoidance to adaptive cruise control, Automotive PCBs are the backbone of ADAS, ensuring real-time data processing and reliable connectivity. The demand for smarter, safer vehicles pushes automakers to integrate more sophisticated electronics. Automotive PCBs must meet stringent durability, heat resistance, and signal integrity standards. Unlike consumer electronics, these PCBs endure harsh conditions while maintaining precision. As ADAS evolves, the role of an Automotive PCB becomes even more critical in enabling autonomous driving.

Why Automotive PCB Is Essential for ADAS Functionality

ADAS features like lane-keeping assist and automatic braking depend on rapid data transmission. Automotive PCBs facilitate this by connecting sensors, cameras, and control units. Their multi-layer designs ensure high-speed signal routing without interference. ADAS would struggle to process information fast enough to prevent accidents without robust PCBs.

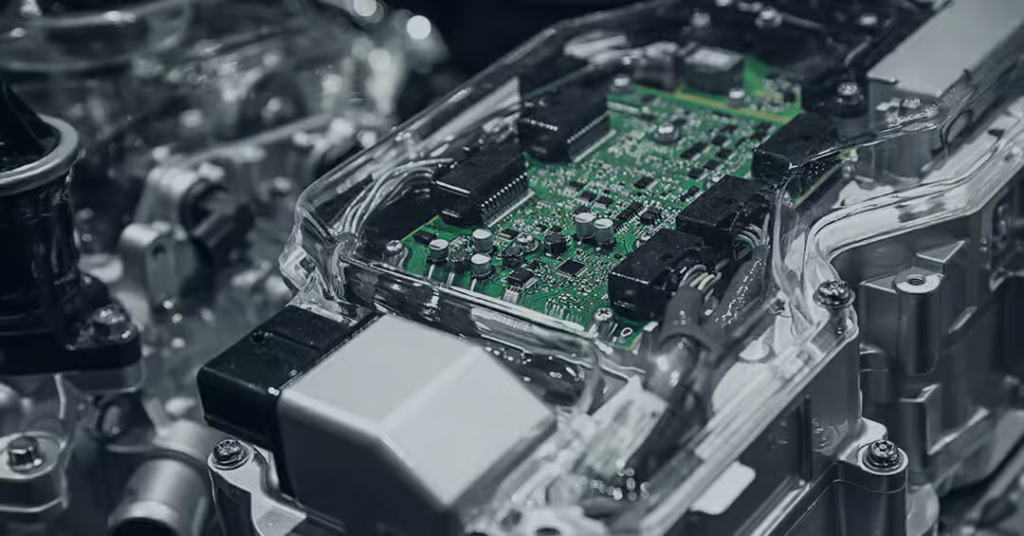

Moreover, Automotive PCBs must withstand extreme temperatures and vibrations. Manufacturers use materials like high-Tg laminates to enhance thermal stability. These specialized PCBs also integrate advanced EMI shielding to prevent signal distortion. As a result, they deliver consistent performance even in demanding environments.

Key ADAS Features Enabled by Automotive PCB

Adaptive cruise control (ACC) is a prime example of ADAS powered by Automotive PCBs. Radar and LiDAR sensors send real-time data to the vehicle’s control module via high-frequency PCBs. These boards process inputs instantly, adjusting speed to maintain safe distances. Any delay could compromise safety, emphasizing the need for ultra-reliable PCBs.

Similarly, blind-spot detection systems rely on compact, high-density PCBs. These boards connect ultrasonic sensors and warning indicators seamlessly. Their miniaturized designs allow integration into tight spaces without sacrificing performance. As ADAS grows more complex, Automotive PCBs will continue enabling innovative safety features.

Cutting-Edge Materials and Designs Driving ADAS Advancements

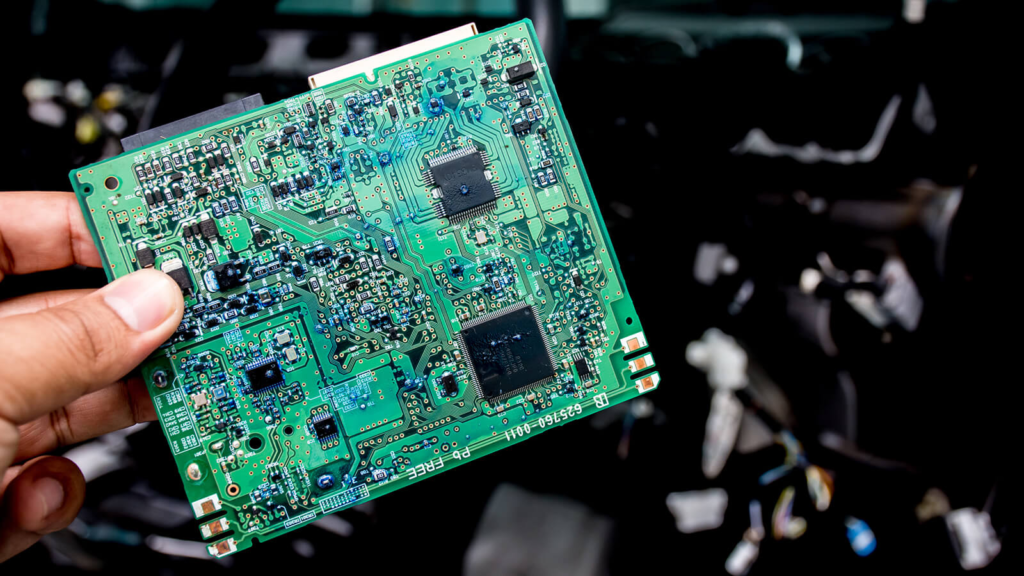

Traditional PCBs can’t handle the rigors of automotive applications. Instead, Automotive PCB uses copper-heavy substrates for better conductivity. Some employ ceramic-filled materials to dissipate heat efficiently. These enhancements ensure longevity, even under constant thermal cycling.

Flex and rigid-flex PCBs are also gaining traction. Their bendable nature allows placement in unconventional areas, such as around curved dashboards. This flexibility supports advanced sensor arrays while reducing wiring complexity. As ADAS demands grow, so will the need for innovative PCB designs.

Overcoming Manufacturing Challenges in ADAS Circuit Boards

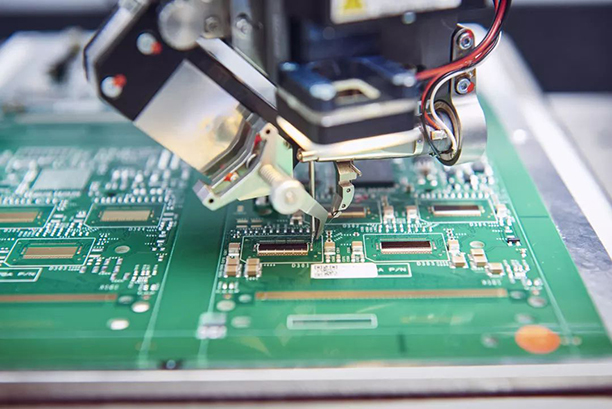

Producing Automotive PCB for ADAS isn’t without hurdles. Manufacturers must meet ISO 26262 functional safety standards. Even minor defects can lead to system failures, making quality control paramount. Automated optical inspection (AOI) and X-ray testing help detect flaws early.

Another challenge is balancing cost and performance. High-reliability materials and processes drive up expenses. However, cutting corners isn’t an option when human lives are at stake. Leading PCB suppliers invest in R&D to optimize production without compromising safety.

Next-Gen Circuit Boards Powering Autonomous Vehicle Evolution

Automotive PCB will play an even bigger role as cars reach full autonomy. They’ll need to support AI-driven decision-making with ultra-low latency. Future PCBs may incorporate embedded components to save space and boost speed.

5G connectivity will also influence PCB design. Faster data transfer requires advanced RF capabilities. Manufacturers are already experimenting with hybrid PCBs that combine analog and digital circuits. These innovations will shape the next generation of ADAS and self-driving cars.

How Consumers Benefit from Advanced Automotive PCBs

Drivers may not see Automotive PCB, but they experience their benefits daily. High-quality PCBs provide smoother adaptive cruise control, accurate parking assist, and reliable emergency braking, which reduce driver fatigue and prevent collisions.

Additionally, longer-lasting PCBs mean fewer repairs. Vehicles equipped with premium Automotive PCBs maintain performance over time. As ADAS becomes standard, consumers can expect safer, more efficient rides.

Automotive PCB – The Unsung Heroes of ADAS

Automotive PCBs are indispensable, from enabling basic safety alerts to supporting full autonomy. They bridge the gap between sensors, processors, and actuators, ensuring ADAS functions flawlessly. These PCBs will evolve as technology advances, bringing us closer to accident-free roads.

Investing in high-quality Automotive PCBs isn’t just about better electronics—it’s about saving lives. Whether you’re a car buyer or an engineer, understanding their role helps you appreciate the complexity behind modern driving aids. The future of transportation hinges on these tiny yet mighty circuit boards.