What are the Advantages of Using Gold Finger PCB in Electronics?

Printed Circuit Boards are essential components that provide the physical foundation for electronic circuits. The Gold Finger PCB has earned a reputation for superior functionality and reliability among the various types of PCBs available. This blog post explores the advantages of using Gold Finger PCBs, particularly in high-performance and demanding applications.

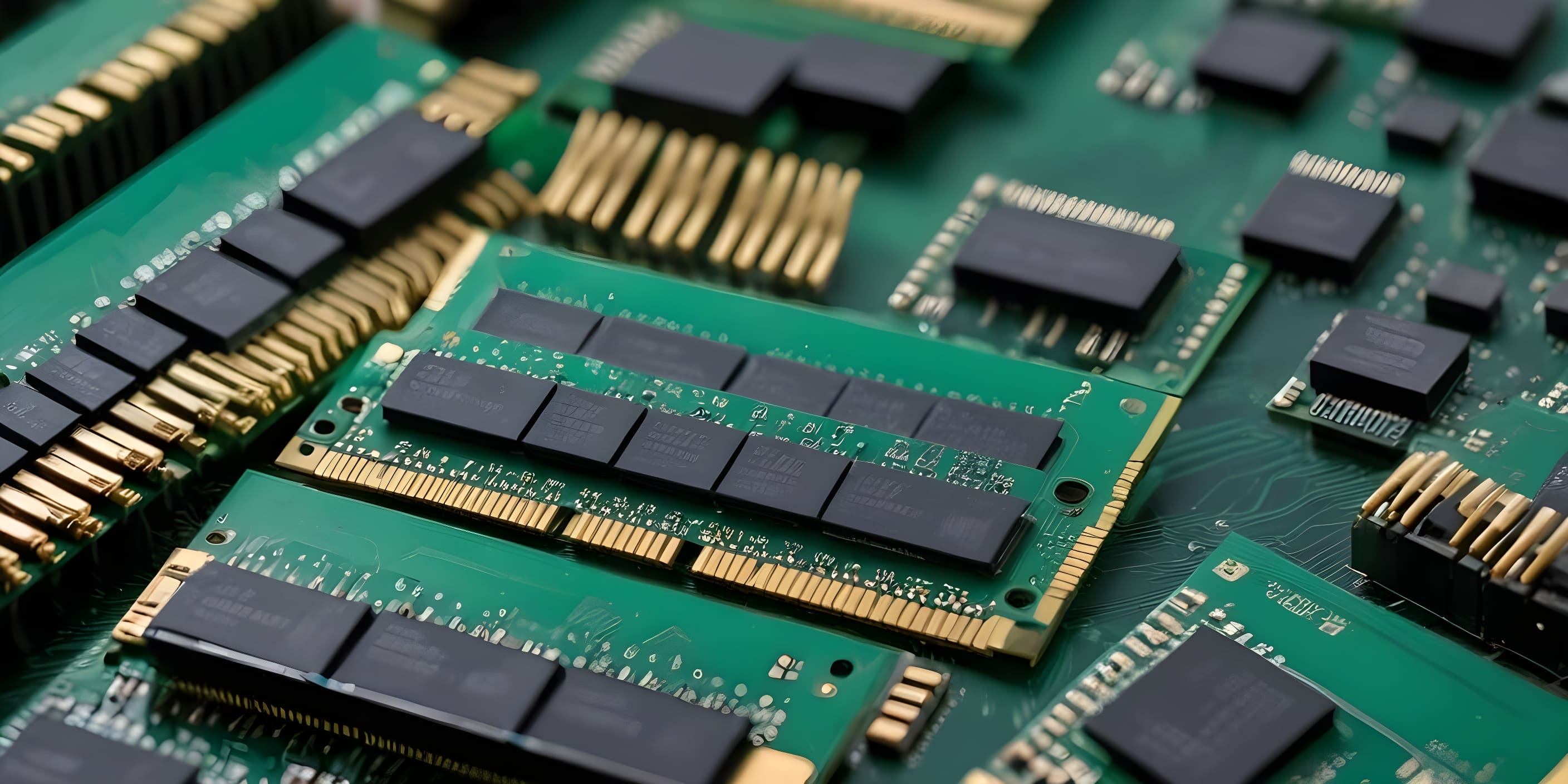

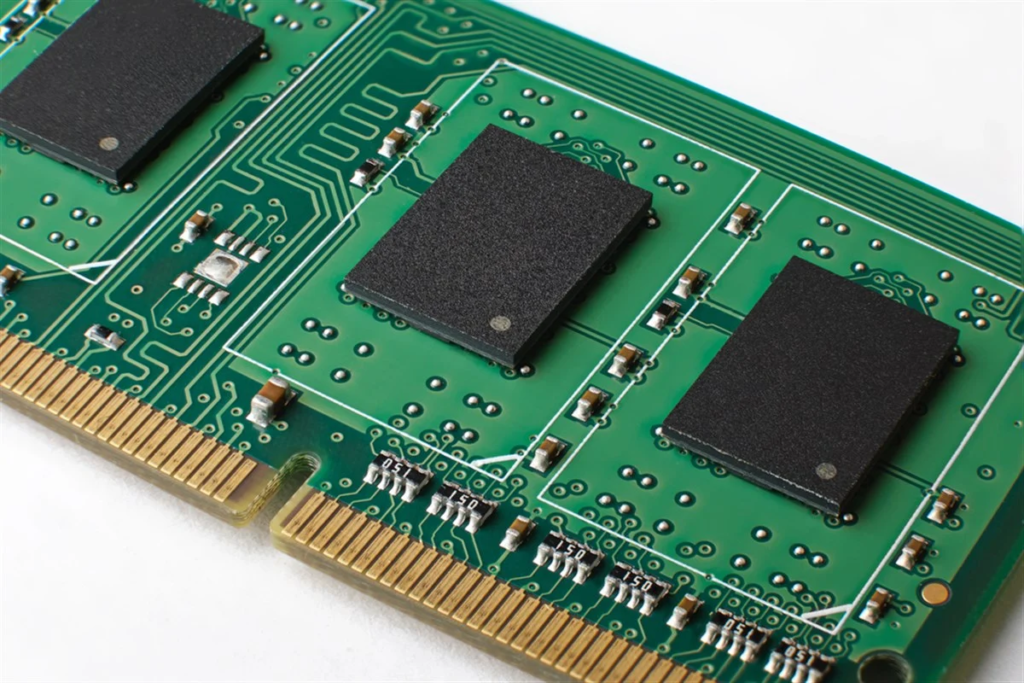

Gold Finger PCB Introduction

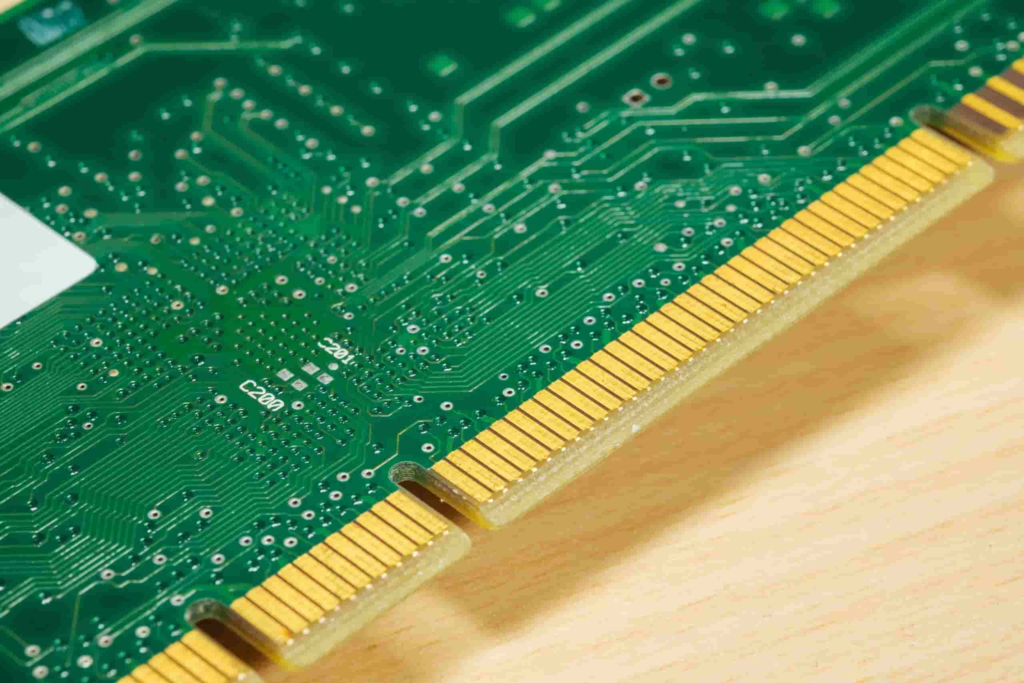

Gold Finger PCBs stand out with their gold-plated connectors, commonly known as ‘gold fingers.’ These connectors are crucial in applications where reliable electrical connections are necessary for high-speed data transmission or heavy current handling. The gold plating applied to the edges of the PCB, where the connectors interface with other parts of an electronic device, is a unique feature. Gold’s excellent conductivity and resistance to corrosion ensure long-lasting performance in challenging conditions, setting Gold Finger PCBs apart from other types.

Manufacturers typically use gold finger connectors in applications where the PCB is designed to plug into a socket or slot, such as computer motherboards, graphics cards, and industrial equipment. Gold’s durability, combined with its resistance to oxidation, allows for a secure, low-resistance connection even after frequent use. This makes Gold Finger PCBs ideal for situations where performance and longevity are paramount.

The specific use of gold plating on the connectors also helps minimize signal loss and ensures a stable transmission of data, which is critical for high-speed applications. Whether for consumer electronics or industrial machines, Gold Finger PCBs offer significant advantages over non-plated alternatives.

Superior conductivity and performance

The material’s superior conductivity is the most significant advantage of using a Gold Finger PCB. Gold is one of the best conductors of electricity, allowing electrical signals to flow with minimal resistance. This results in better signal integrity and faster data transmission speeds.

Signal degradation can be a serious issue for high-speed applications, such as telecommunications, gaming systems, and computer processors. The gold plating on the PCB’s connectors helps minimize this problem. Gold’s natural resistance to corrosion and oxidation ensures that the conductive properties remain optimal over extended periods.

A study by the IPC highlighted the importance of material choice in PCBs, with gold being one of the top performers in terms of longevity and conductivity. In real-world applications, manufacturers frequently use Gold Finger PCBs in systems that require high-frequency signals, such as broadband communication devices, where data transmission must be both fast and reliable.

High Durability and Long Service Life

Another key benefit of Gold Finger PCBs is their outstanding durability. Gold is resistant to corrosion and wear, which makes it a long-lasting solution in environments subject to frequent usage and harsh conditions. Gold-plated connectors ensure that the PCB will perform optimally over time, regardless of exposure to humidity, extreme temperatures, or repeated mechanical stress.

This long-lasting performance is critical in mission-critical applications where downtime is costly. For example, maintaining a reliable connection is vital in industrial machinery, automotive electronics, and aerospace systems. In such scenarios, Gold Finger PCBs provide higher reliability than alternatives that may suffer from signal degradation or failure due to oxidation or other environmental factors.

The robustness of gold plating means that Gold Finger PCBs can maintain their integrity for many years, helping companies avoid costly repairs or replacements. This increased durability reduces the overall cost of ownership, making these PCBs a cost-effective choice in the long run.

Excellent Corrosion Resistance and Protection

One of the most notable characteristics of Gold Finger PCBs is their exceptional corrosion resistance. While most metals oxidize and degrade over time, gold remains inert, which doesn’t react with environmental factors like oxygen or moisture. This makes gold-plated connectors especially useful in electronics exposed to fluctuating humidity, salt water, or high temperatures.

Corrosion can lead to poor electrical connections, signal loss, and electronic device failure. Due to its significant impact, manufacturers must mitigate corrosion in critical systems such as medical devices, military equipment, and automotive controls. Gold’s natural resistance to corrosion ensures that Gold Finger PCBs can continue to function in even the most challenging environments without the risk of deterioration.

As a result, Gold Finger PCBs are frequently used in outdoor or industrial applications where equipment is exposed to harsh weather conditions or chemical exposure. With gold’s inherent protective properties, manufacturers can produce electronics with greater confidence in their reliability and performance over the long term.

Cost-effective for high-volume production

Though the initial cost of gold plating may be higher than other alternatives, using Gold Finger PCBs can prove highly cost-effective in the long run, particularly in high-volume production scenarios. The enhanced performance, durability, and reduced need for maintenance or replacement make Gold Finger PCBs a more affordable option. Manufacturers can expect significant cost savings from reduced failures and returns, making the decision to use Gold Finger PCBs in their products a sound investment.

Manufacturers often decide to use Gold Finger PCBs in their products because of the cost savings from reduced failures and returns. Products that rely on high-speed data transmission or need to maintain consistent performance over time benefit significantly from the longevity of gold-plated connectors.

Gold Finger PCBs often result in fewer quality control issues during production. The PCB’s overall reliability improves because the gold plating reduces the likelihood of corrosion, oxidation, or other performance issues. This leads to fewer defects in the final product and reduces the cost of warranty claims or repairs.

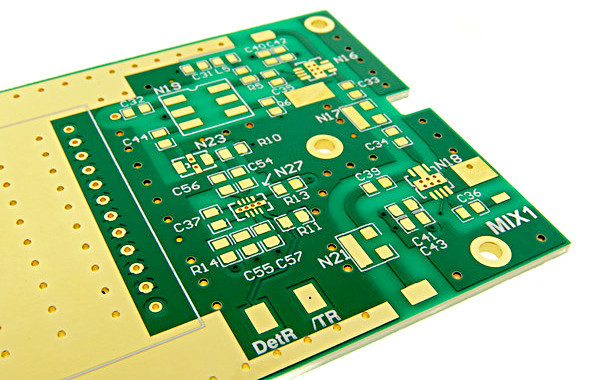

With versatility and application flexibility

The electronics industry widely uses Gold Finger PCBs because of their versatility. These PCBs suit various applications, from consumer electronics to industrial and automotive systems. The flexibility of gold-plated connectors allows for their use in both low- and high-power circuits, making them ideal for everything from basic electronics to cutting-edge devices.

Gold finger connectors are also essential in devices that require frequent connection and disconnection, such as computer graphics cards or high-speed networking equipment. The durability of the gold plating ensures that these connectors can handle multiple cycles of insertion and removal without losing their conductivity or performance.

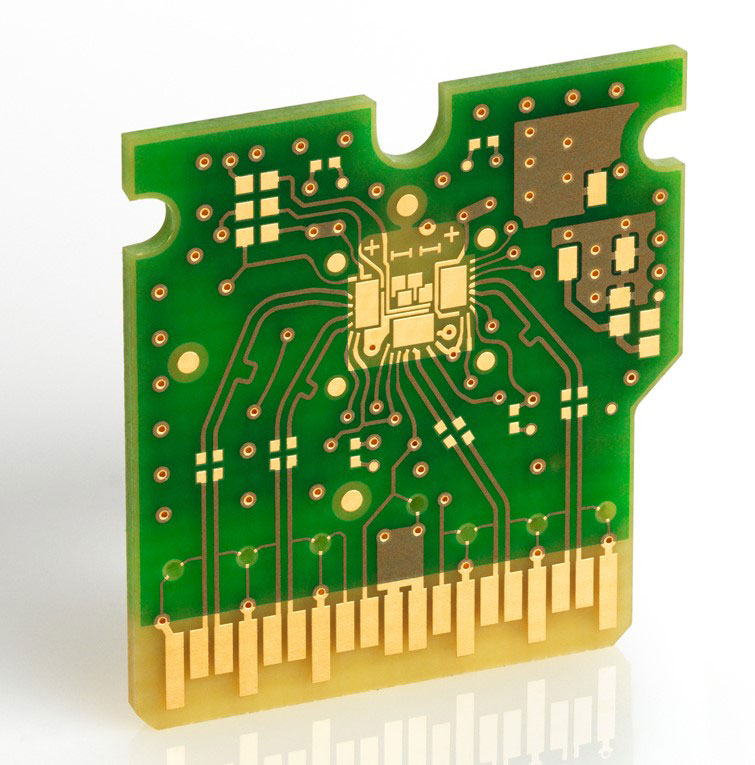

Moreover, Gold Finger PCBs support various mechanical designs and can be customized to meet specific application requirements. Whether it’s for high-density connectors, small form-factor boards, or high-frequency circuits, these PCBs provide a reliable and adaptable solution that meets the needs of various industries.

The Future of Gold Finger PCB in Electronics

The use of Gold Finger PCBs is expected to grow even further as electronic devices become more complex and demand for higher performance increases. With the rise of 5G technology, artificial intelligence (AI), and the Internet of Things (IoT), the need for reliable, high-speed connections is more significant than ever. Gold Finger PCBs are poised to play a crucial role in meeting these demands, signalling a promising future for these advanced electronic components.

In high-speed data applications, such as 5G networks and data centres, gold-plated connectors ensure that large amounts of data are transmitted without interference or loss. As the digital landscape evolves, manufacturers will continue to rely on Gold Finger PCBs to deliver the high performance, durability, and security necessary for the next generation of electronics.

As technology advances, new materials and innovations in PCB manufacturing will likely complement gold’s already established advantages, further enhancing its role in electronics. However, Gold Finger PCBs remain an indispensable part of many industries, providing both immediate and long-term benefits for manufacturers and end-users alike.

Gold finger PCB is the first choice for the electronics industry

Gold Finger PCBs offer a range of advantages that make them a top choice in the electronics industry. These benefits are evident, from superior conductivity and corrosion resistance to enhanced durability and cost-effectiveness. As the demand for high-performance electronics continues to grow, the role of Gold Finger PCBs will only become more significant. Whether for consumer electronics, industrial applications, or cutting-edge technologies, Gold Finger PCBs provide the reliability and longevity required for today’s demanding electronic environments.