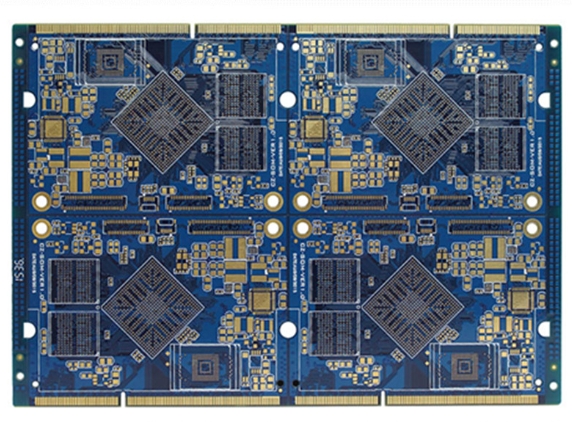

What are the common materials used in 8 layer SSD PCB?

For SSDs, especially those that require strong performance and stability, the choice of materials in 8-layer SSD PCBs is very important. This guide will introduce the common materials used in 8 layer SSD PCB, emphasizing their importance, characteristics, and applications. By understanding these materials, you can have a clearer understanding of the SSD PCBs we provide for you.

FR-4: The Backbone of 8 layer SSD PCB

FR-4 is one of the most widely used materials in producing 8-layer SSD PCBs. It is a composite material of woven glass fiber cloth and flame-retardant epoxy resin adhesive, where FR stands for flame retardant. FR-4 is the most used material due to its excellent mechanical strength, electrical insulation properties, and cost-effectiveness. They can provide a stable foundation for high-speed signal transmission and reliable performance under various environmental conditions. In addition, the versatility of FR-4 makes it suitable for a wide range of applications, from consumer electronics to industrial machinery. Its ability to maintain structural integrity and electrical performance under thermal stress makes it the most commonly used choice for 8-layer SSD PCBs.

High-Frequency Laminates: Enhancing Signal Integrity in 8-layer SSD PCBs

As SSDs evolve, the need for higher data transfer rates and improved signal integrity has led to the adoption of high-frequency laminates in 8-layer SSD PCBs. These laminates, which include Rogers or Taconic materials, have excellent dielectric properties and low-loss characteristics, making them suitable for high-speed and high-frequency applications. At the same time, high-frequency laminates reduce signal attenuation and maintain signal integrity over longer distances, which is critical for the reliable operation of advanced SSDs. While these materials are more expensive than traditional FR-4, their performance advantages justify their selection in applications where signal integrity is critical.

Polyimide Provides Durability and Heat Resistance

Polyimide is another common material used in 8-layer SSD PCBs, especially in applications that require high thermal stability and flexibility. They can withstand higher temperatures than FR-4, making them suitable for environments with significant thermal stress. This material is also highly flexible and can be used for innovative design solutions such as flexible circuits and dynamic bending applications. At the same time, they also have excellent chemical and solvent resistance, which ensures that the 8-layer SSD PCB maintains its integrity under various operating conditions. Due to the fast data processing speed and dense component placement, the 8 layer SSD PCB may generate much heat during operation. This material can withstand high temperatures, often up to 260°C (500°F) or more without degradation. This high thermal stability makes it an ideal material for 8-layer SSD PCBs.

Using Metal Core PCBs

Thermal management is essential to SSD design, especially for high-performance applications. Metal core PCBs enhance thermal conductivity and effectively dissipate the heat generated by electronic components. These PCBs contain a metal layer within the substrate to conduct heat away from critical components. Using MCPCBs in 8-layer SSD PCBs helps maintain optimal operating temperatures, prevent thermal throttling, and improve overall reliability. In addition, by reducing thermal stress on components, MCPCBs help extend the life of the SSD. Lower operating temperatures reduce the risk of thermal degradation and failure, improving the device’s overall reliability. MCPCBs are also particularly useful in powering data centers, gaming systems, and other high-power applications.

Resin Systems Improve the Performance of 8-Layer SSD PCBs

The resin system is carefully designed to have a low dielectric constant, essential for high-frequency signal integrity. This property reduces signal loss and attenuation, efficiently transmitting data between 8-layer SSD PCB layers. In addition, advanced resin systems provide excellent insulation between conductive layers, thereby reducing crosstalk and electromagnetic interference (EMI). This ensures that signals remain clear and distinct, which is critical to maintaining the high-speed data integrity required by SSDs. At the same time, resin systems often contain fillers or additives that enhance thermal conductivity. This allows for more efficient heat dissipation of critical components such as memory chips and controllers, preventing overheating and ensuring stability.

Use the Right Materials

Material selection for an 8-layer SSD PCB is a critical factor affecting the performance, reliability, and lifespan of the final product. Materials such as FR-4, high-frequency laminates, polyimide, metal core PCB, advanced resin systems, etc. all play a unique role in optimizing the functionality of the SSD.