What are the key applications of power supply PCB in industrial electronics?

Power supply PCB is an integral component in industrial electronics, providing a crucial link between the electrical supply and electronic systems. Whether regulating voltage, converting current, or distributing power, these PCBs ensure electronic devices operate efficiently and reliably. This article explores the key applications of power supply PCBs in industrial electronics, highlighting their versatility and importance across various industries.

The Role of Power Supply PCBs in Industrial Electronics

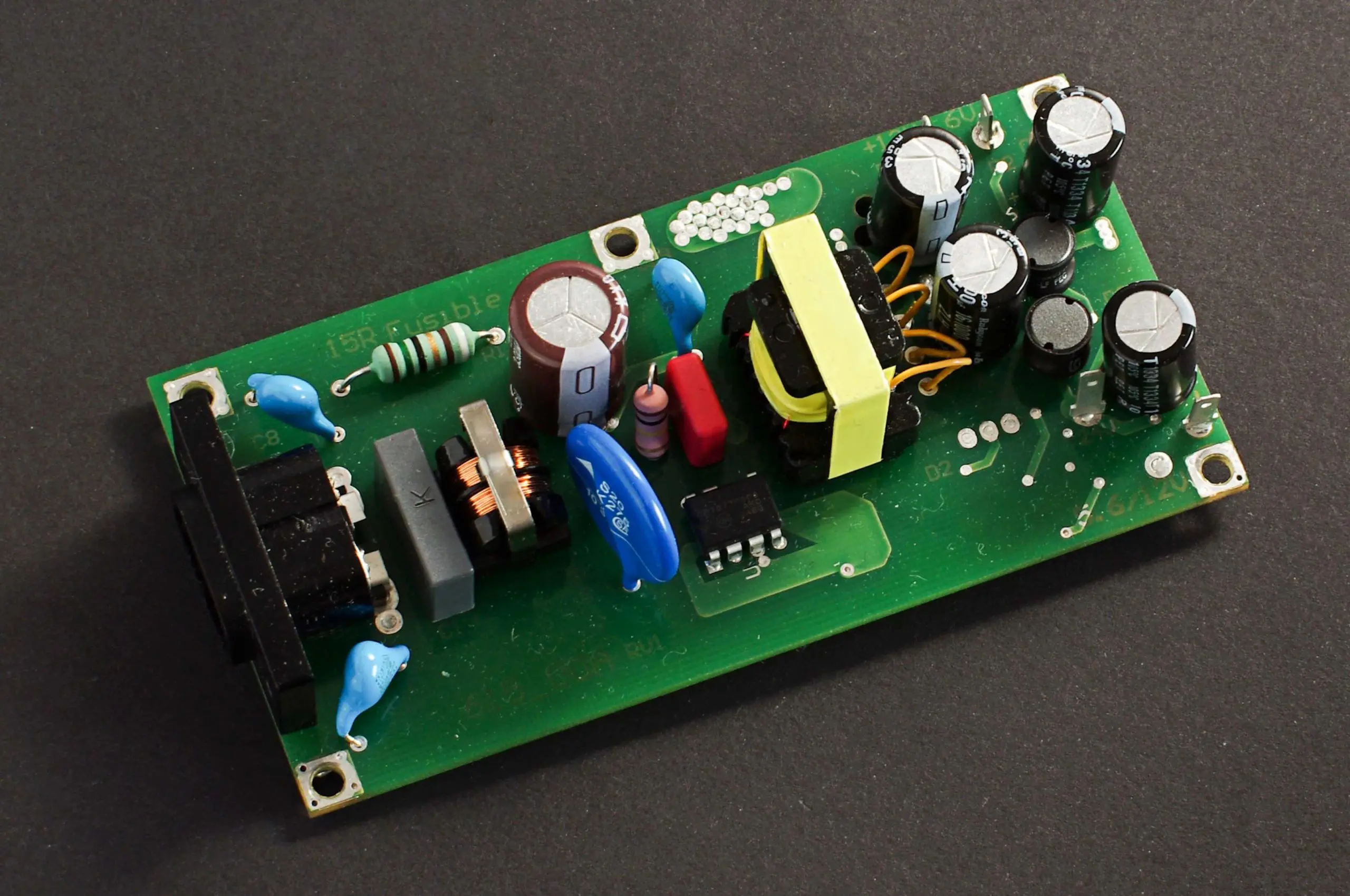

Power PCBs are fundamental to efficient power distribution in electronic systems. It connects power to components within a device, ensuring that each part receives the correct voltage and current. Industrial electronic devices ranging from automation systems to robotics and telecommunications rely on these PCBs for optimal performance.

In industrial environments, reliability and efficiency are critical. Power PCBs play a pivotal role in ensuring the safety of operations by minimizing energy loss, reducing heat generation, and protecting sensitive components from voltage fluctuations. By stabilizing power, they extend the life of machines and equipment, providing a sense of security. Manufacturing, automotive, and telecommunications industries rely heavily on these PCBs to meet stringent power demands and ensure continuous operation.

Applications in Industrial Automation Systems

Industrial automation is one of the largest sectors utilizing power supply PCBs. These systems rely on the precise control and management of power to ensure that machines and processes run smoothly. Power supply PCBs in automation equipment regulate the voltage and current required by motors, sensors, controllers, and other critical components.

For example, programmable logic controllers (PLCs), the brains of automation systems, often use specialized power supply PCBs to ensure a stable power supply. These PCBs help maintain efficient operations when uptime is crucial, such as assembly lines or packaging plants. By providing stable power, these PCBs help reduce the risk of downtime caused by power issues and enhance the overall productivity of industrial operations.

Automation systems are not just a present reality, but also an exciting future prospect. With the evolution of Industry 4.0, which integrates advanced technologies such as AI, robotics, and IoT, these systems are becoming more complex. As these systems evolve, the role of power supply PCBs in ensuring smooth and uninterrupted power flow becomes even more critical, paving the way for an exciting future in industrial automation.

Applications in Industrial Robotics

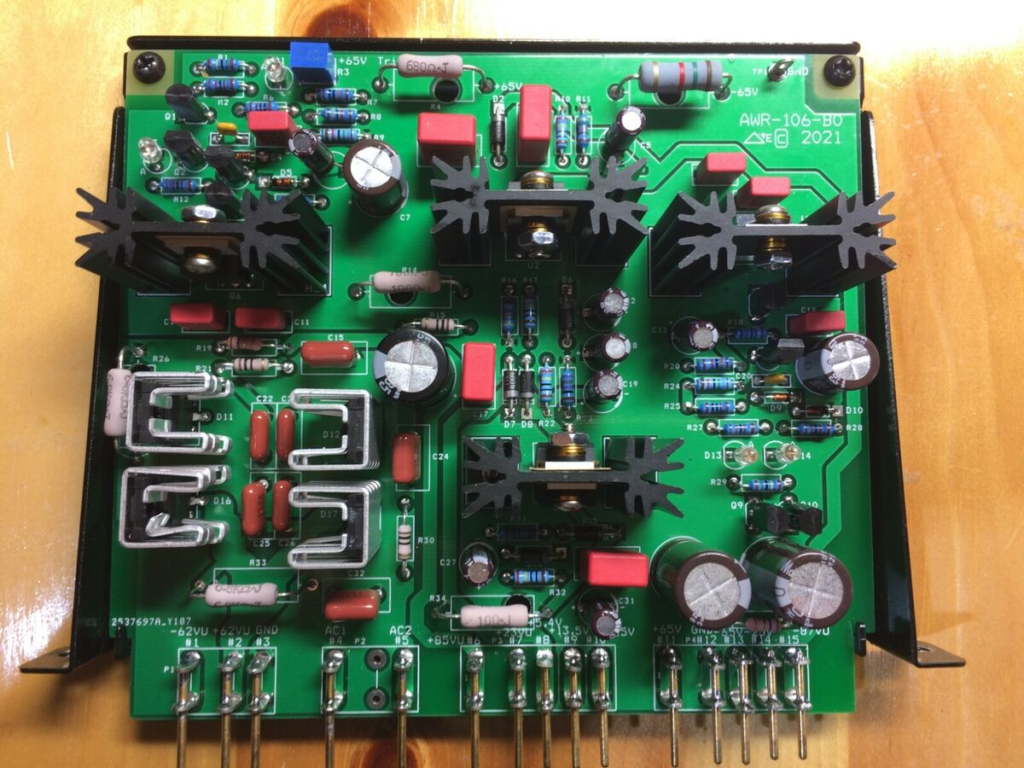

Industrial robotics is another key area where power supply PCBs play a vital role. Robots, particularly in manufacturing, require precise power regulation to control motors, actuators, sensors, and other electronic components that drive their movements and decision-making processes. Power supply PCBs in these systems must deliver stable and efficient power to support these robots’ complex tasks.

For example, robotic arms used in assembly lines rely on power supply PCBs to maintain consistent power to their servos and sensors, which control the arm’s movement and operation. These PCBs protect against overvoltage, short circuits, and thermal issues, ensuring the robotic systems remain safe and efficient during operation.

As the robotics industry advances, the demand for power supply PCBs that can handle higher precision, reliability, and energy efficiency levels increases. With the growing adoption of collaborative robots (cobots) in industrial settings, these PCBs are becoming more sophisticated to meet the evolving demands of the robotics market.

Power Supply PCBs in Telecommunications Equipment

The telecommunications industry relies heavily on power supply PCB to support various equipment, from cell towers and switches to servers and data centres. These PCBs convert and distribute electrical power to telecommunications components, often requiring high-density and low-voltage regulation.

Telecommunication networks demand continuous operation, making the role of power supply PCBs crucial in maintaining the infrastructure’s reliability. Power supply PCBs in telecommunications equipment are designed to handle varying power demands, ensuring the network remains functional even during power surges or outages.

For instance, base stations that transmit mobile signals rely on robust power supply PCBs to ensure stable power for radio frequency (RF) modules and signal processors. With the introduction of 5G networks, the demand for power supply PCBs with higher power efficiency and smaller form factors has increased. This trend is pushing the industry toward more innovative and compact PCB designs.

Applications in the Electric Vehicle Sector

Another sector in which power supply PCBs play a significant role is the electric vehicle (EV) industry. These PCBs manage EVs’ power distribution and charging systems, ensuring that batteries are charged efficiently and power is supplied to the vehicle’s electric motors and other electronic components.

Power supply PCBs in EVs must handle high loads, especially when managing the vehicle’s battery charging and discharging processes. These PCBs regulate the voltage and current to ensure the safe and efficient operation of the battery pack. They also protect the vehicle’s electrical system from potential issues like overcharging or short circuits.

As the EV market grows, driven by the global shift toward sustainable transportation, the role of power supply PCBs becomes even more significant. These PCBs play a crucial role in managing EVs’ power distribution and charging systems, ensuring that batteries are charged efficiently and power is supplied to the vehicle’s electric motors and other electronic components. This significant role of power supply PCBs in the growth of the EV market brings optimism about the industry’s future.

Applications in Medical Device Manufacturing

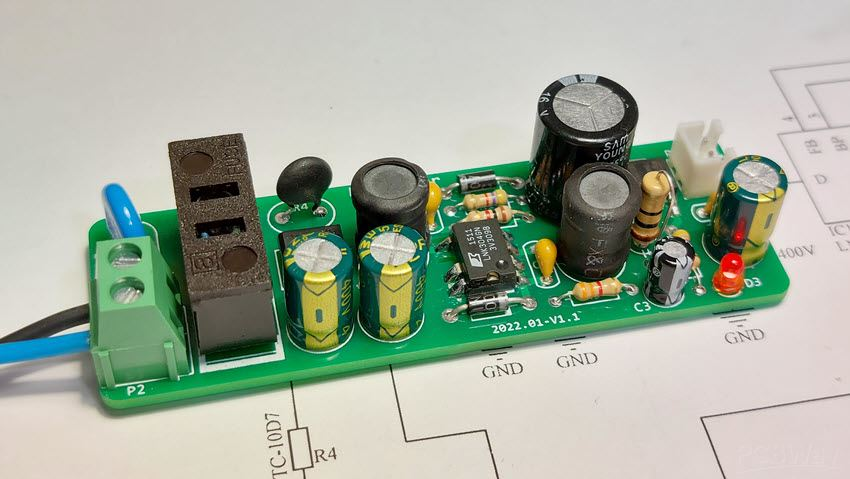

Power supply PCBs are crucial for ensuring life-saving equipment operates without failure in the medical industry. Medical electronics, from diagnostic tools like MRI machines to life support devices like ventilators, require a consistent and stable power supply to function correctly. These power supply PCBs are designed with high reliability and safety standards to prevent power-related malfunctions in critical applications.

For instance, defibrillators require a specialized power supply PCB that ensures rapid and accurate power delivery to deliver shocks to the heart. These PCBs are also designed to ensure compliance with medical industry regulations, such as IEC 60601, which sets safety and performance standards for medical electrical equipment.

As medical devices become more advanced, with technologies like wearable health monitors and connected diagnostic tools, the power supply of PCBs must become more compact, energy-efficient, and reliable. The ongoing advancements in medical technology drive innovation in power supply PCB design to meet these demands.

The Future of Power Supply PCB in Industrial Electronics

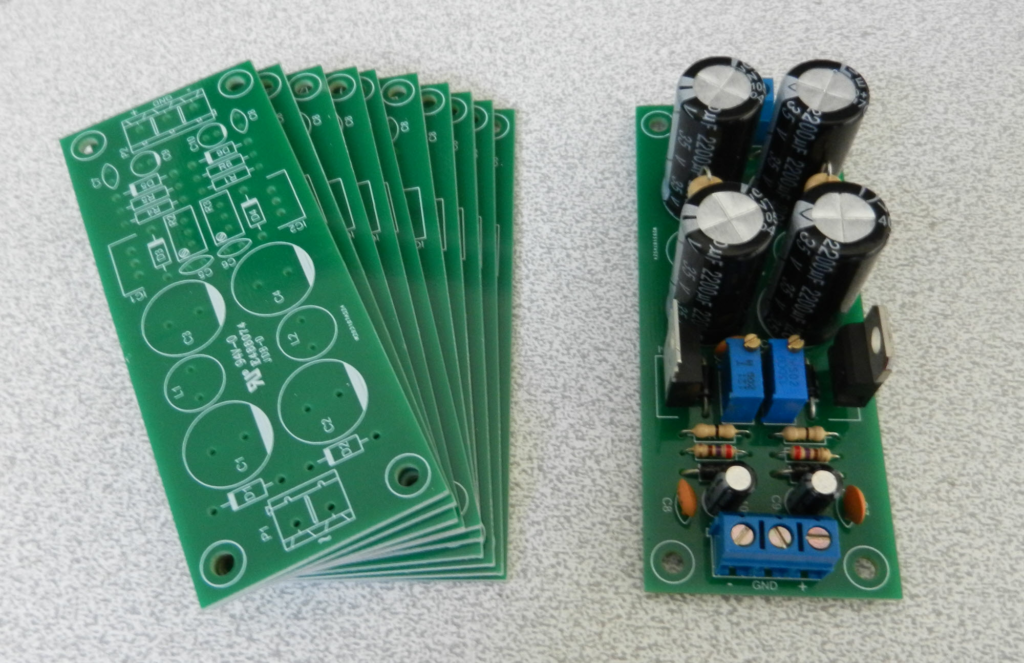

As the demand for more energy-efficient and reliable power management systems continues to rise, the future of power supply PCBs in industrial electronics looks promising. Advancements in materials science, such as the use of flexible PCBs and 3D-printed PCBs, are paving the way for more compact and customizable designs. Additionally, emerging technologies such as wide bandgap semiconductors (e.g., silicon carbide) enable power supply PCBs to operate at higher efficiencies and temperatures, especially beneficial for industries like electric vehicles and renewable energy.

The increasing trend towards smart manufacturing and Industry 4.0 also influences the design of power supply PCBs. With the integration of sensors, automation systems, and IoT devices, the need for highly reliable and flexible power solutions is greater than ever. Power supply PCBs must adapt to support these innovations while ensuring stability and durability in demanding industrial environments.

The Critical Role of Power Supply PCBs in Modern Industrial Applications

Power supply PCBs are critical for powering the devices and systems that drive industrial electronics. From automation and robotics to telecommunications and electric vehicles, these PCBs ensure power is distributed effectively and reliably. As industries continue to innovate, the demand for advanced power supply PCBs that meet high efficiency, reliability, and safety standards will only increase, making them indispensable in modern industrial applications.