What are the main benefits of rigid flex PCB for electronic devices?

As electronics become smaller, faster, and more advanced, the technology behind them must also evolve. rigid flex boards are a solution to the needs of modern devices, combining the durability of rigid boards with the flexibility of flexible circuits. From wearable devices to aerospace systems, rigid flex PCB offers reliable performance, space-saving designs, and greater efficiency. They are changing how electronic devices are manufactured, solving design challenges, and enabling innovative solutions. Next, we’ll explore the key benefits of rigid-flex PCB and why they’re the top choice for today’s electronic devices.

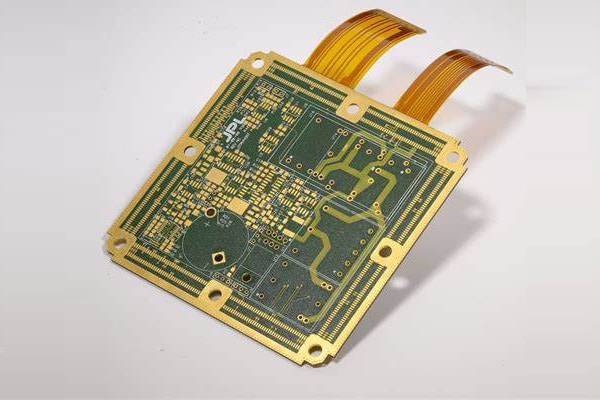

Overview of rigid flex PCBs

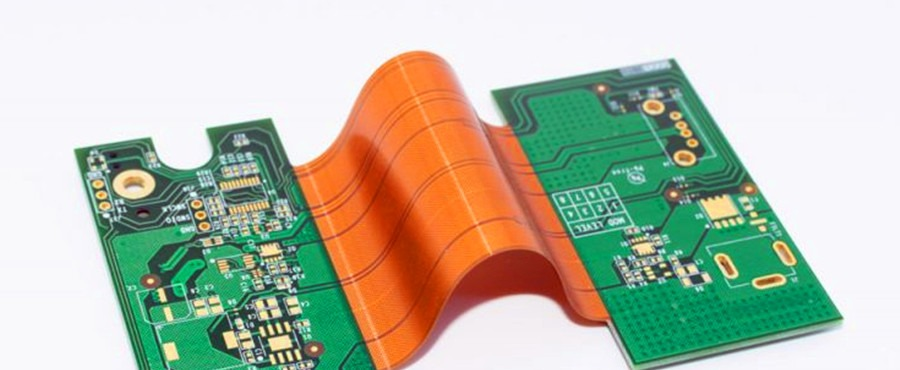

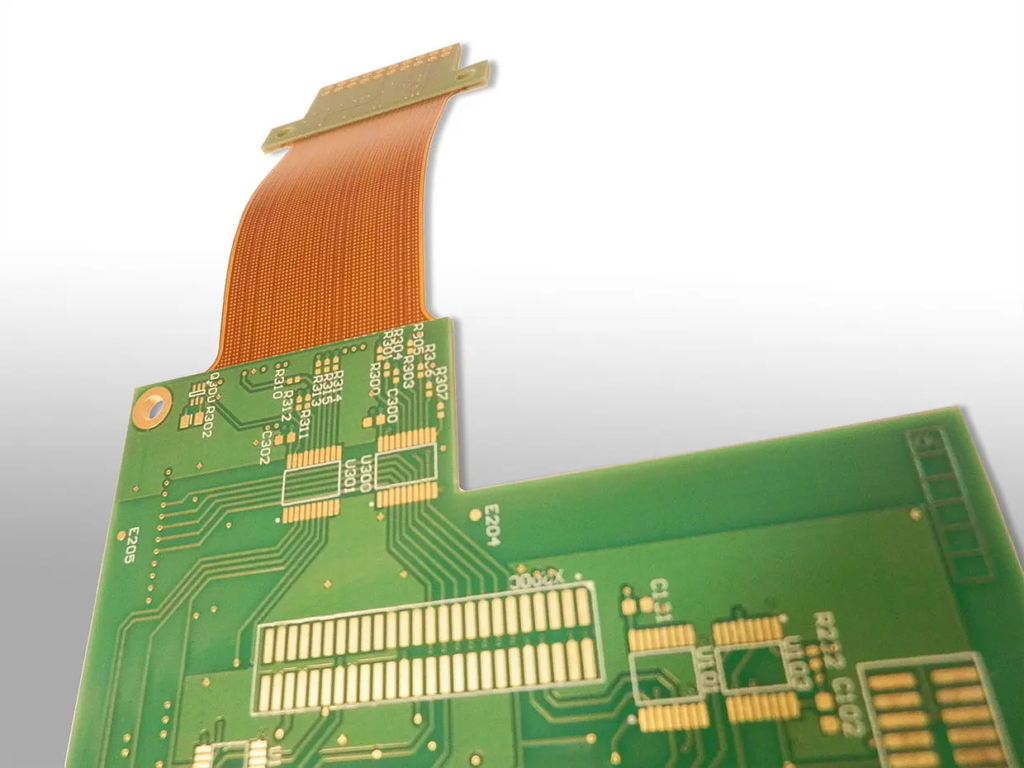

rigid flex PCBs, a hybrid of rigid and flexible circuit boards, represent one of the most transformative innovations in the electronics industry. By merging rigid boards’ strengths with flexible circuits’ adaptability, rigid flex PCBs deliver unparalleled functionality. These advanced boards cater to the growing demand for compact, reliable, high-performance electronics across various industries, inspiring new technological possibilities.

The global trend towards miniaturized and multifunctional devices has significantly increased the importance of rigid flex PCBs. These boards play a crucial role in the design of wearable technologies, medical equipment, and aerospace systems, meeting stringent requirements for space efficiency, durability, and precision; according to a report by MarketsandMarkets, the global rigid flex PCB market is expected to grow from $2.5 billion in 2023 to $3.6 billion by 2028, underscoring its expanding role in the electronics sector.

Design Versatility: Expanding Creative Boundaries with rigid flex PCB

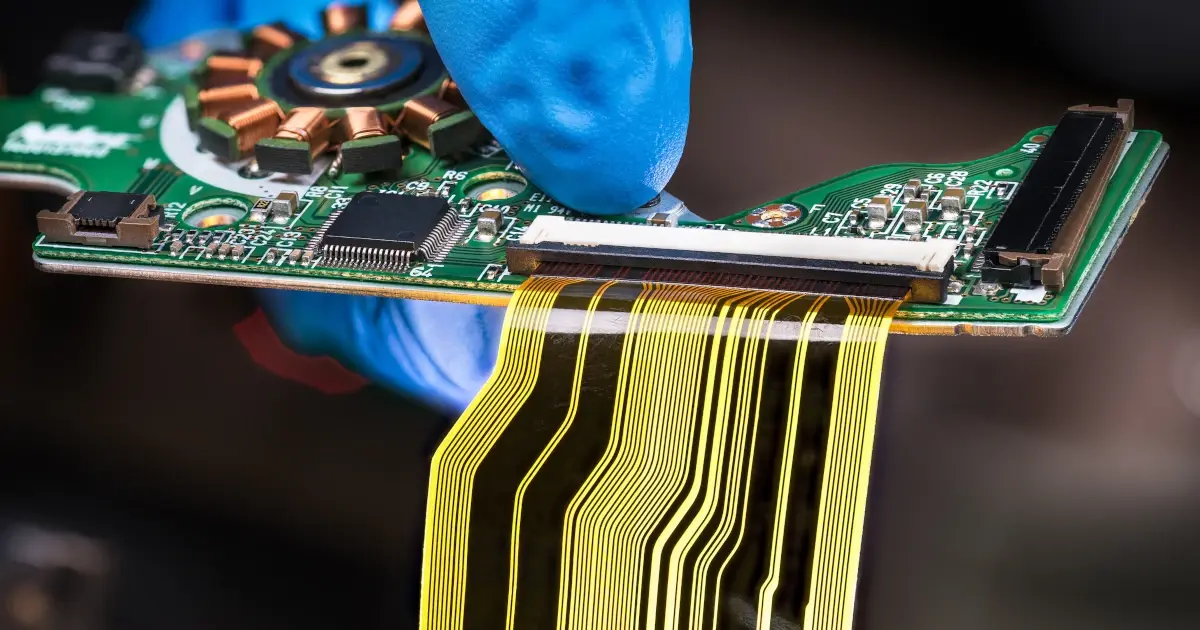

One of the standout benefits of rigid flex PCBs is their unmatched design versatility. Unlike traditional circuit boards, rigid flex PCBs allow for the seamless integration of rigid and flexible layers, enabling three-dimensional configurations. This capability opens new possibilities for device miniaturization and optimized space utilization.

Compact and wearable devices, such as fitness trackers and smartwatches, are prime products that benefit from this design freedom. These devices require intricate circuitry within a small and often curved form factor. rigid flex PCBs facilitate such designs without compromising performance or reliability. Furthermore, rigid flex PCBs enable lightweight yet robust solutions in aerospace and defense applications, where every gram of weight matters.

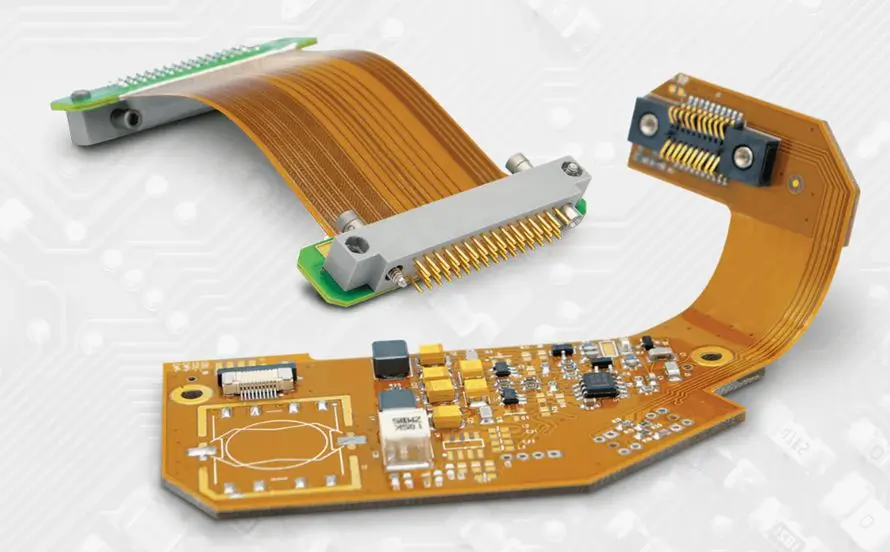

The elimination of bulky connectors and excess cabling further enhances design flexibility. This streamlined approach reduces potential points of failure and simplifies assembly. For example, in automotive applications, rigid flex PCBs are used in advanced driver-assistance systems (ADAS) to connect sensors, cameras, and control modules efficiently. Their ability to adapt to complex designs ensures that engineers can create innovative solutions tailored to the specific needs of modern technology.

Durability and Reliability: Meeting Demands in Challenging Environments

Durability is critical in electronics, mainly when operating in harsh or demanding environments. rigid flex PCBs excel in this aspect, combining the mechanical strength of rigid boards with the flexibility to withstand motion and vibration. Their robust construction ensures long-term reliability, even under extreme conditions.

rigid flex PCBs are found in engine control systems and in-vehicle infotainment modules in automotive applications. These systems endure constant vibration and temperature fluctuations, and rigid flex PCBs maintain stable performance. Similarly, these boards resist wear and tear from repetitive movements and heavy-duty operations in industrial equipment.

A key contributor to their durability is using high-quality materials like polyimide, known for its excellent thermal and mechanical properties. rigid flex PCBs can operate across a wide temperature range, making them suitable for aerospace applications, where extreme heat and cold are standard. Their ability to endure challenging conditions without failure reduces maintenance costs and ensures uninterrupted device functionality.

Signal Integrity: Enhancing Precision and Performance

Signal integrity is vital for high-speed and precision electronics, and rigid flex PCBs offer significant advantages. Eliminating external connectors and cables minimizes electrical noise and signal interference, resulting in cleaner and more reliable data transmission.

This feature is precious in medical devices like imaging systems and monitoring equipment. For instance, wearable heart monitors rely on stable signal pathways for accurate readings. rigid flex PCBs provide the necessary precision, enabling healthcare professionals to make informed decisions based on real-time data.

Additionally, rigid flex PCBs support shorter signal paths, reducing delay and improving overall device performance. These characteristics greatly benefit telecommunications equipment, which demands high-frequency operation. rigid flex PCBs ensure seamless communication, even in complex network infrastructures, by maintaining consistent signal quality.

Cost Efficiency: Balancing Performance and Affordability

While rigid flex PCBs may have higher initial production costs, they offer substantial long-term savings, making them a cost-effective choice. By consolidating multiple components into a single, unified design, these boards simplify assembly and reduce the need for additional connectors and cables. This streamlined approach minimizes production time and lowers the risk of errors during manufacturing.

Smartphones and tablets are prime examples of devices that leverage this cost-efficiency. These devices require compact designs with integrated components, and rigid flex PCBs enable manufacturers to meet these demands without escalating costs. Furthermore, the enhanced reliability of these boards reduces maintenance expenses for end-users, contributing to their overall value.

By gaining a competitive advantage, businesses can achieve higher production yields and faster time to market. In addition, rigid flex PCBs’ long lifespan and reduced failure rates make them a sustainable choice, aligning with the electronics industry’s increasing emphasis on eco-friendly practices.

Superior Thermal Management: Keeping Electronics Cool

Thermal management is a critical factor in ensuring the longevity and efficiency of electronic devices. rigid flex PCBs excel, offering effective heat dissipation through flexible sections and advanced material composition. This capability is essential for devices operating in high-power or high-temperature environments.

LED lighting systems are a notable application where rigid flex PCBs shine. By efficiently dissipating the heat generated by LEDs, these boards prolong the lights’ lifespan and maintain consistent brightness levels. Similarly, effective thermal management in computing devices prevents processor overheating and ensures reliable performance under heavy workloads.

rigid flex PCBs offer dependable performance for aerospace and defense applications, where thermal extremes are a given. Their ability to manage heat effectively contributes to device reliability, reducing the likelihood of failure during critical operations.

Future Applications: Bridging Innovation and Sustainability

The versatility of rigid flex PCBs makes them indispensable in emerging technologies and applications. With the advent of 5G and IoT, the demand for compact, high-performance circuit boards is increasing. rigid flex PCBs are paving the way for innovations like flexible displays, implantable medical devices, and autonomous vehicles.

One exciting development is their use in foldable smartphones, where rigid flex PCBs enable seamless bending and folding without compromising functionality. Similarly, in smart home systems, these boards provide the compact and efficient circuits needed for interconnected devices.

From a sustainability perspective, rigid flex PCBs support reduced material usage and extended product lifespans. This aligns with global efforts to minimize waste and promote environmentally friendly manufacturing practices. By investing in rigid flex PCBs, businesses can be leaders in innovation and sustainability.

The Essential Role of rigid flex PCBs in Modern Electronics

rigid flex PCBs are transforming the landscape of electronic device design and functionality. Their unique versatility, durability, and efficiency combination make them essential in cutting-edge industry technologies. As the demand for compact, reliable, and high-performance devices continues to rise, rigid flex PCBs will remain at the forefront of innovation.