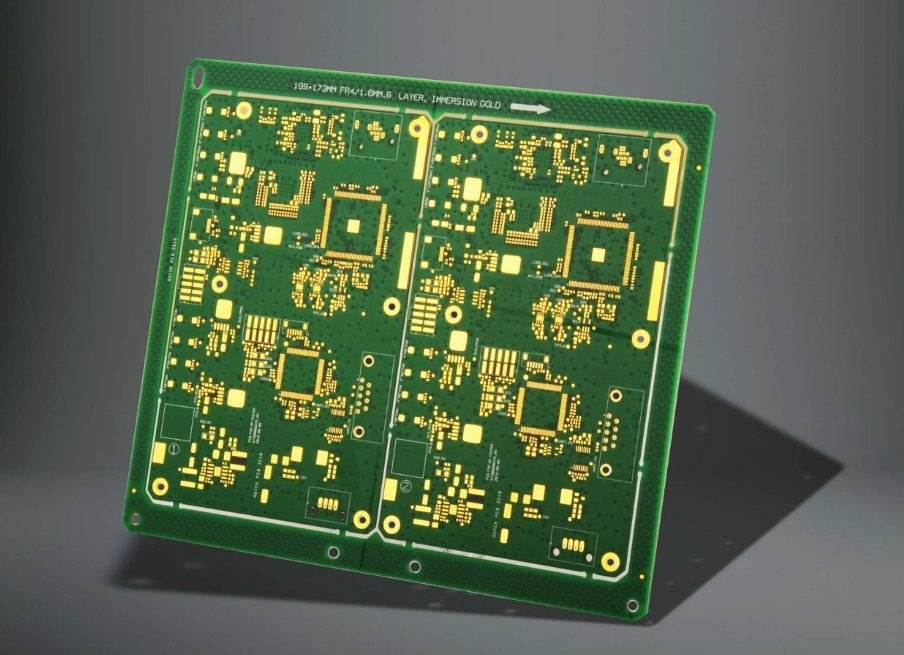

What industries commonly use multilayer FR4 PCB?

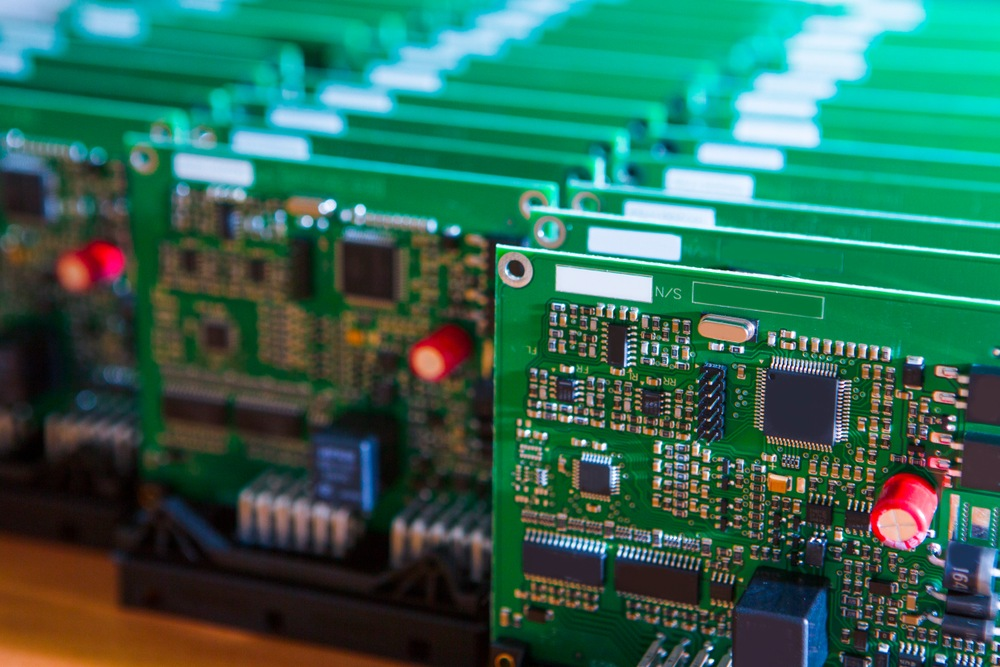

Multilayer FR4 PCBs have become foundational in manufacturing due to their durability, compact size, and ability to handle complex circuit designs. Electronics and aerospace industries rely on FR4-based PCBs for high-efficiency performance in constrained spaces. As the world embraces technological advancements, multilayer FR4 PCBs continue to support innovations and enhance performance across numerous sectors. We will explore how multilayer FR4 PCBs benefit various industries, covering details that can help users make informed decisions when selecting PCB solutions.

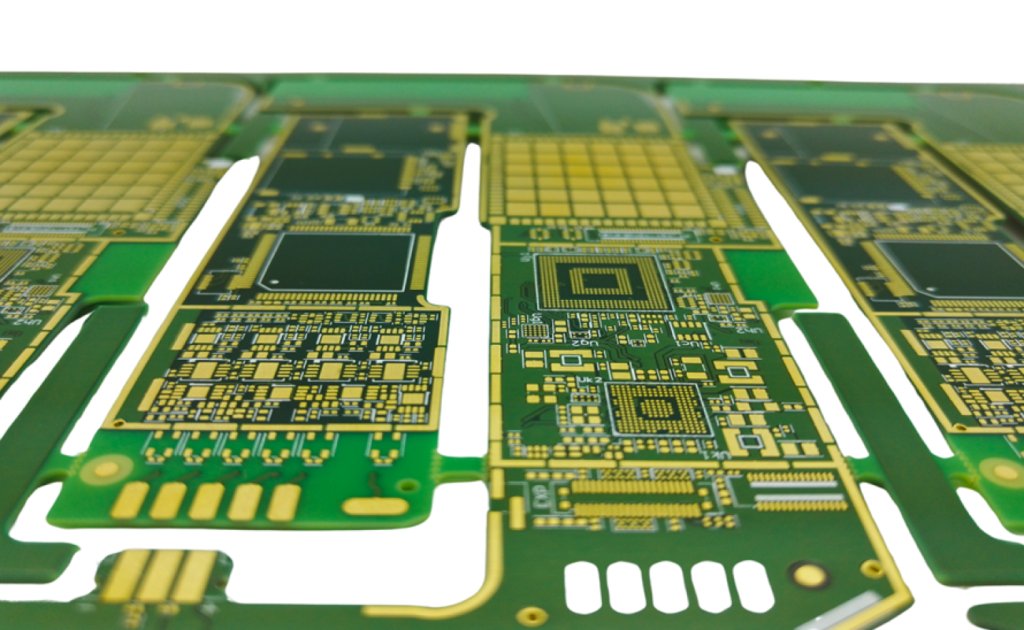

Multilayer FR4 PCB in Consumer Electronics

Consumer electronics represent one of the most significant sectors utilizing multilayer FR4 PCBs, as devices like smartphones, laptops, gaming consoles, and smartwatches demand high-density, high-performance circuit boards. In particular, a primary benefit of multilayer FR4 PCBs in this industry is their ability to enable compact, reliable designs that support advanced features without compromising durability. Moreover, with each layer facilitating a different function, these PCBs can handle complex processes essential to modern devices’ operation.

For example, a multilayer FR4 PCB manages various smartphone functions such as touch sensors, wireless communication, and battery management. This integration allows manufacturers to meet consumer expectations for slim, lightweight, yet powerful devices. As more devices incorporate IoT functionality, demand for multilayer PCBs is expected to grow exponentially. The integration of advanced PCB designs in consumer electronics highlights the adaptability of multilayer FR4 PCBs in meeting the constantly evolving demands of tech-savvy consumers worldwide.

Applications in the automotive manufacturing sector

Multilayer FR4 PCBs are crucial in the automotive industry’s transition to more computerized vehicles. By enabling manufacturers to incorporate complex electronic systems within limited dashboard space, they become essential for functionalities like ABS, GPS, and vehicle-to-vehicle communication. Consequently, this transition underscores the remarkable adaptability of multilayer FR4 PCBs in meeting the industry’s constantly evolving demands.

Electric vehicles (EVs) and hybrid models particularly benefit from multilayer FR4 PCBs due to their efficiency in managing high-power loads within compact spaces. The ability to withstand temperature fluctuations is crucial in automotive applications, as the components must endure varying operational environments without failure. Automotive manufacturers increasingly rely on FR4 PCBs due to their reliability in sustaining consistent performance under diverse conditions. The future of self-driving cars and advanced automotive features further underscores the importance of robust, multilayer PCB designs.

Applications in the Telecommunications Industry

The telecommunications sector is significantly transitioning towards more advanced 5 G and fiber-optic networks. Multilayer FR4 PCBs are crucial in this transition, providing efficient data transmission, networking, and communication applications. Components like routers, satellites, and mobile base stations use these PCBs to handle data flow without interference, ensuring high-speed connectivity.

As 5G networks expand, telecommunications equipment must meet higher standards for performance and stability. Multilayer FR4 PCBs provide the ideal structure to support low latency and high-speed data processing, allowing devices to meet the rigorous demands of modern telecommunication systems. For instance, fiber-optic devices and base stations can transmit vast amounts of data without delays, which is essential in global connectivity and digital transformation. Telecommunication providers rely on FR4 PCBs to maintain seamless communication channels for commercial and consumer needs.

Applications in the Field of Medical Devices

The medical device industry has stringent requirements for reliability and precision, making multilayer FR4 PCBs a top choice for medical equipment. MRI machines, pacemakers, and portable diagnostic tools depend on multilayer PCBs for stable, compact circuitry that withstands intensive use and varying environmental conditions. FR4 PCBs are also used to monitor patients and must consistently deliver accurate results.

In portable medical diagnostic devices, multilayer FR4 PCBs enable high-density configurations that support data processing, signal transmission, and energy efficiency within a compact footprint. Additionally, regulatory standards in the healthcare industry require high durability and reliability, qualities that multilayer FR4 PCBs meet effortlessly. As medical technology advances with wearable health monitors and remote diagnostics, multilayer FR4 PCBs will continue to play an instrumental role in supporting life-saving applications.

Applications in Aerospace and Defense

The aerospace and defense sectors often operate in extreme conditions, requiring electronic components that can withstand high temperatures, vibrations, and environmental stresses. In response to these demands, multilayer FR4 PCBs meet these rigorous standards, making them suitable for avionics, communication systems, radar equipment, and satellites. Furthermore, their ability to endure extreme conditions without compromising performance makes them ideal for such high-stakes environments.

For example, multilayer PCBs in satellite communication systems support uninterrupted signal transmission and data processing, which is critical for maintaining communication between space and ground stations. In defense, reliable PCBs are also essential for mission-critical functions like navigation, radar, and surveillance. As aerospace and defense technology evolves with more demanding electronic requirements, multilayer FR4 PCBs are expected to remain at the forefront, providing stable, resilient solutions for complex applications.

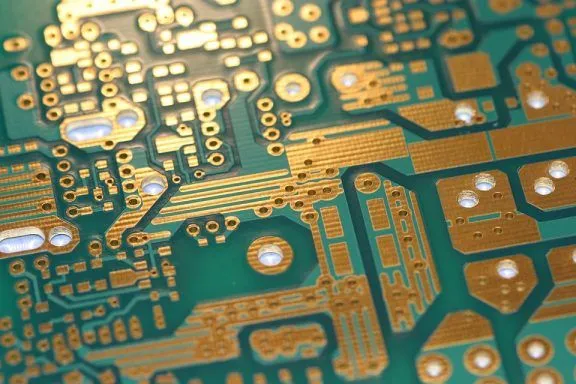

Applications in Industrial Manufacturing

In industrial automation, multilayer FR4 PCBs are indispensable in robotics, control systems, and heavy machinery applications. Industrial environments demand equipment that can handle substantial power loads and withstand continuous operation, which multilayer FR4 PCBs deliver with high efficiency. These PCBs are designed to distribute electrical loads evenly and manage heat effectively, ensuring long-lasting and reliable operation in high-power applications.

For instance, robotics in manufacturing plants relies on multilayer PCBs to control and execute precise movements and handle extensive data flows from various sensors. Similarly, factory control systems, like programmable logic controllers (PLCs), use FR4 PCBs to manage complex tasks seamlessly. The robustness of multilayer FR4 PCBs in harsh environments makes them ideal for industrial automation, supporting the efficiency and productivity of modern manufacturing processes.

Renewable Energy and the Role of Multilayer FR4 PCB

Renewable energy applications, particularly solar and wind energy, utilize multilayer FR4 PCBs for energy management and conversion systems. In solar power systems, multilayer PCBs support inverters that convert direct current (DC) generated by solar panels into alternating current (AC) used by most electronic devices. Their capacity to handle high power loads and withstand various environmental conditions makes them suitable for renewable energy applications.

Wind turbines use multilayer FR4 PCBs in their control systems to manage power generation and distribution. These PCBs help maintain stable energy output and protect equipment from environmental factors like moisture and temperature fluctuations. As renewable energy technology progresses, the reliability and efficiency of multilayer FR4 PCBs are essential to optimize energy output and reduce the carbon footprint associated with power generation.

Selecting the Right Multilayer FR4 PCB for Industry-Specific Needs

Multilayer FR4 PCBs are essential across numerous industries, from consumer electronics and automotive to telecommunications, healthcare, aerospace, industrial automation, and renewable energy. Their durability, reliability, and high-density layout capabilities make them invaluable in supporting complex applications. By understanding the unique benefits of multilayer FR4 PCBs in each sector, users can make informed choices to enhance product performance and achieve long-lasting solutions. For manufacturers and industries looking to stay ahead in innovation and efficiency, multilayer FR4 PCBs offer the versatility needed to meet evolving demands.