What materials are commonly used in the production of 6 layer set-top box PCB?

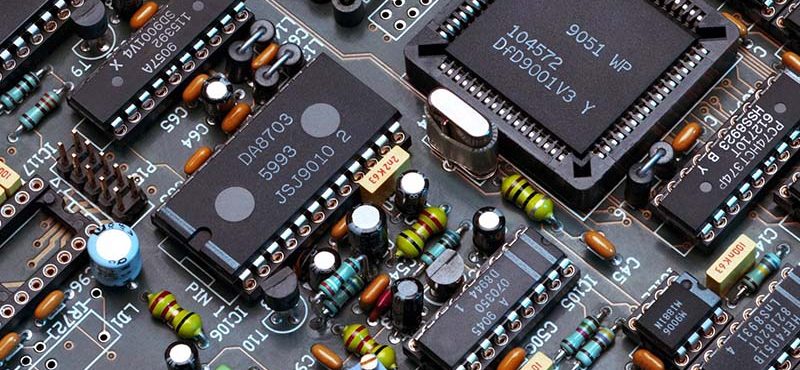

When it comes to the design and manufacture of electronic devices, particularly set-top boxes, the printed circuit board (PCB) serves as the backbone of functionality and connectivity. A 6 layer set-top box PCB is precisely engineered to meet the demands of modern multimedia applications, combining efficiency, durability, and high performance. In this article, we’ll explore the materials commonly used in producing 6 layer set-top box PCBs, highlighting their importance and impact on the overall quality of the final product.

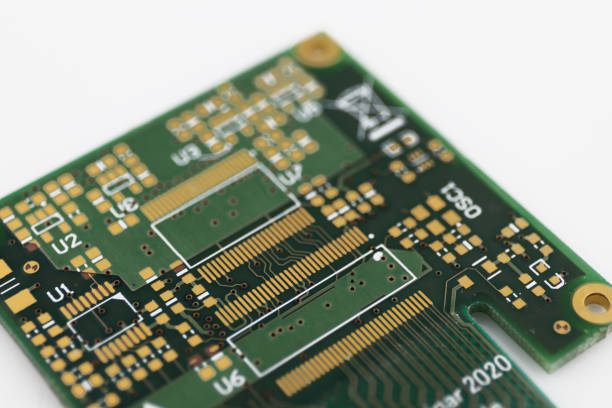

Understanding the Structure of a 6 Layer Set-Top Box PCB

A 6 layer set-top box PCB typically consists of six conductive layers separated by insulating layers. The layers are arranged to optimize signal integrity and reduce electromagnetic interference (EMI), which is crucial for high-frequency applications like video streaming and digital broadcasting. The materials selected for each layer significantly determine the PCB’s performance, durability, and cost-effectiveness.

Each layer serves specific functions, from signal transmission to power distribution, which necessitates careful selection of materials that can handle these varying roles. Understanding each layer’s structure and purpose helps recognize the importance of material choice in manufacturing.

Core Materials for 6 Layer Set-Top Box PCBs

The manufacturer primarily makes a 6-layer set-top box PCB core material from FR-4, a fiberglass-reinforced epoxy laminate. Researchers favor this material for its excellent dielectric properties, mechanical strength, and thermal stability.FR-4 provides a good balance of cost and performance, making it a popular choice in the PCB industry.

Other specialized materials, such as polyimide, may also be used for high-temperature applications or where flexibility is required. The choice of core material directly affects the PCB’s overall performance, reliability, and lifespan, making it a critical consideration in the design process.

Dielectric Materials and Their Role in Signal Integrity

Dielectric materials are crucial for separating the conductive layers in a 6 layer set-top box PCB. These materials have a high dielectric constant and low loss factor, which helps maintain signal integrity and minimize energy loss during transmission. Common dielectric materials include PTFE (Teflon), which offers excellent thermal and chemical resistance.

The choice of dielectric material can influence the PCB’s impedance control, which is vital for high-speed signal transmission. Selecting the appropriate dielectric material ensures that the set-top box operates efficiently and reliably, even under demanding conditions.

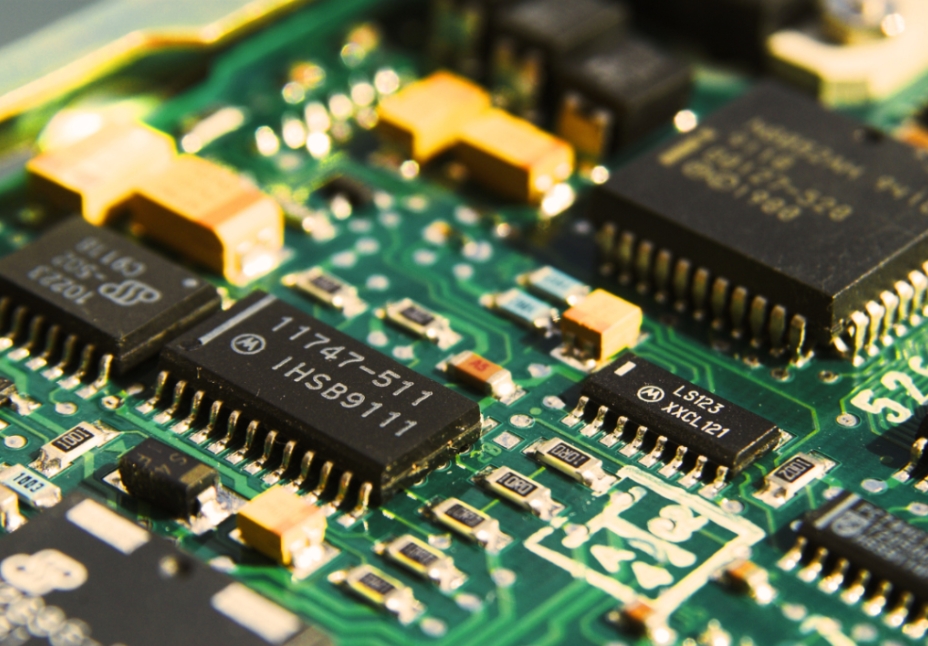

Copper is a standard conductive material.

Copper is the standard conductive material used in 6 layer set-top box PCBs. Manufacturers prefer it for its excellent electrical and thermal conductivity and malleability, which make it ideal for etching intricate circuit designs. The thickness of the copper layers can vary, typically ranging from 1 oz to 3 oz, depending on the application’s current-carrying requirements.

In addition to standard copper, manufacturers often apply surface treatments such as ENIG (Electroless Nickel Immersion Gold) to improve solderability and prevent oxidation. These enhancements ensure reliable connections and prolong the lifespan of the PCB, especially in devices exposed to harsh environments.

Solder Mask and Silkscreen Materials

The solder mask is a polymer coating applied to the PCB to protect the copper traces from oxidation and contamination. It also helps prevent solder bridges during assembly. Common solder mask materials include epoxy and liquid photoimageable (LPI) materials, which provide excellent adhesion and durability.

Silkscreen materials, usually in white ink, print labels, logos, and component designators on the PCB surface. The choice of silkscreen material should complement the solder mask to ensure visibility and readability while maintaining the PCB’s overall aesthetics.

Thermal Management Materials for Enhanced Performance

Thermal management is critical to 6 layer set-top box PCB design, especially for high-performance applications. Engineers employ materials such as thermal pads, heat sinks, and thermal interface materials (TIMs) to dissipate heat and maintain optimal operating temperatures effectively.

Using materials with high thermal conductivity, like aluminum or copper heat sinks, can significantly enhance the set-top box’s performance and reliability. Proper thermal management prevents overheating, which can lead to component failure and reduce the PCB’s lifespan.

Future trends in material selection

As technology advances, the materials used to produce 6 layer set-top box PCBs are evolving. Innovations in flexible materials, higher-frequency dielectrics, and environmentally friendly substrates are becoming increasingly important. Manufacturers are also exploring advanced composites with improved strength-to-weight ratios and thermal properties.

Keeping abreast of these trends is crucial for manufacturers and users alike, as the right material choices can significantly impact the performance, durability, and sustainability of set-top box PCBs in the long term.

Understand the importance of 6 layer set-top box PCB production materials

Understanding the materials commonly used in producing 6 layer set-top box PCBs is essential for making informed purchasing decisions. From core materials like FR-4 to advanced thermal management solutions, each material plays a pivotal role in ensuring the performance and reliability of the final product. As technology continues to evolve, staying informed about material innovations will empower organizations to select the best solutions for their specific needs in the competitive landscape of multimedia technology.