What materials are typically used in the construction of 6-layer SSD PCB?

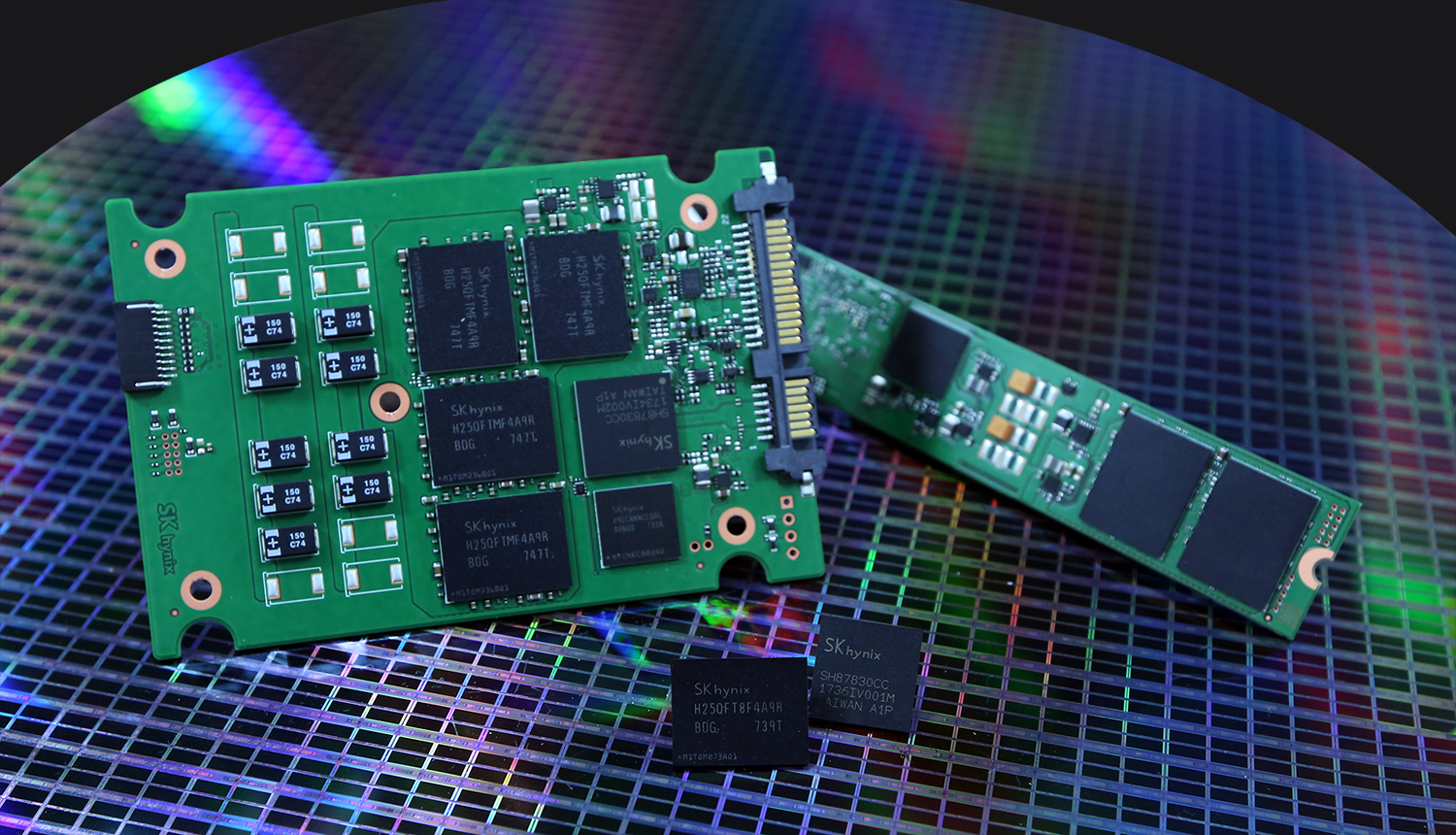

Solid-state drives are essential components in modern computing, providing fast data access and low power consumption. Among the various PCB types used in SSDs, 6-layer SSD PCBs stand out for their ability to offer advanced features, support high-speed data transfer, and ensure optimal performance. Specific materials are needed to build 6-layer SSD PCBs to achieve these features. In this post, we will explore the materials commonly used to construct 6-layer SSD PCBs and how each material affects the overall performance of the SSD.

Core Material: FR4 is a Common Base Material

FR4, the most commonly used substrate in most 6-layer SSD PCBs, is a composite material that consists of woven fiberglass cloth impregnated with epoxy resin. Its excellent thermal stability is crucial for high-density components such as NAND flash memory in SSDs. More importantly, its mechanical strength ensures that the board can withstand the physical stress encountered during manufacturing and use, instilling a sense of durability and reliability in the audience. Using FR4 guarantees that the PCB has adequate performance in electrical insulation, and its excellent dielectric properties help minimize inter-layer crosstalk and improve the overall efficiency of the board in high-frequency operations.

FR4 provides a good balance between mechanical strength, electrical insulation properties, and heat resistance. Manufacturers widely accept it in the industry due to its versatility and cost-effectiveness.

Signal Integrity: One of the Top Considerations for Material Selection

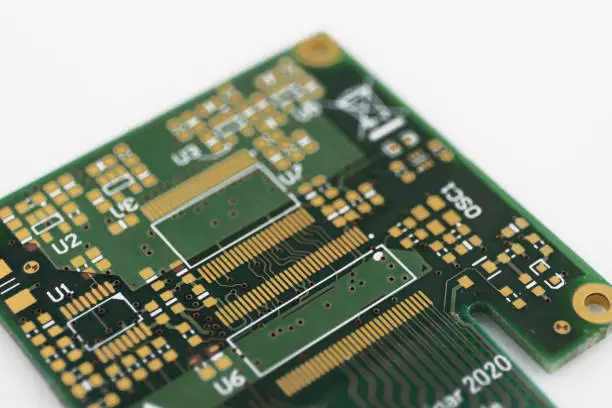

Signal integrity is one of the top considerations for material selection for high-speed applications such as SSDs. In a 6-layer SSD PCB, designers typically use the inner layers for power and ground planes, while the outer layers carry high-speed signal traces. Manufacturers normally incorporate materials with low dissipation factor (Df) and dielectric constant (Dk) values to ensure these high-speed signals maintain integrity throughout the board.

Materials such as low-loss prepregs and high-frequency laminates are crucial in minimizing signal attenuation. For instance, Teflon-based laminates (also known as PTFE laminates) are often used for the inner layers of 6-layer SSD PCBs to reduce signal loss and increase speed. The careful selection of these materials ensures that the SSD can maintain high read/write speeds and maintain performance during intensive data operations, instilling confidence in the audience about the SSD’s performance.

Thermal Management Materials: Impact on Performance and Lifespan of 6-layer SSD PCB

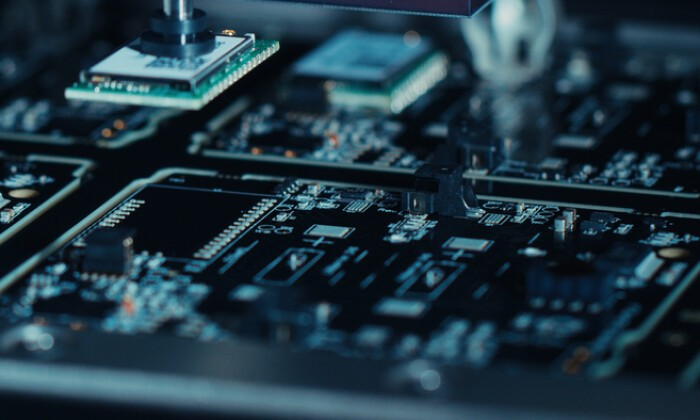

When SSDs process large amounts of data, they generate a lot of heat, which can reduce their performance and lifespan. Therefore, effective heat dissipation materials are a key consideration when manufacturing 6-layer SSD PCBs. Typically, copper is the primary material for these boards’ power/ground planes because of its excellent thermal conductivity. Engineers use thermal vias to direct heat from SSD components to the thermal management layer of the PCB. Designers may add heat sinks or thermal pads to enhance heat dissipation further.

Some 6-layer SSD PCBs also integrate metal core PCBs (MCPCBs) or aluminum-based materials for better thermal conductivity. These materials help keep components cool, thereby improving the reliability of the SSD, mainly when used for long periods or in high-performance environments such as data centers or gaming systems.

Surface Finish Materials: The Role of Solder Mask in 6-Layer SSD PCB

The surface finish of a 6-layer SSD PCB plays a significant role in solderability, electrical performance, and overall durability. Solder mask materials, usually epoxy-based, are used to protect the conductive traces on the PCB, preventing unwanted solder bridges and safeguarding the board from environmental contaminants like moisture and dust.

For 6-layer SSD PCBs, a high-quality solder mask is essential to ensure that the small, dense components of an SSD, such as resistors, capacitors, and connectors, are securely attached and function properly. The surface finish is also essential for high-frequency applications, as it minimizes signal interference that could affect the SSD’s performance.

Standard surface finishes used in 6-layer SSD PCBs include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). Each of these offers different benefits, with ENIG often being the preferred choice for high-speed applications due to its superior flatness and solderability.

Capacitor and Inductor Materials: Ensuring Overall Energy Efficiency and Stable Operation

In a 6-layer SSD PCB, specific components require capacitor and inductor properties to function correctly, especially in power management systems. Integrating materials with high capacitance, such as certain types of ceramic substrates, helps store electrical energy, stabilize power, and filter noise. By incorporating these materials into the design of a 6-layer SSD PCB, manufacturers can ensure that the power integrity of the SSD remains stable and efficient under heavy load conditions, thereby preventing data corruption or failure.

The choice of capacitor and inductor materials directly affects the overall energy efficiency and operational stability of a 6-layer SSD PCB, especially in systems with strict power requirements, such as high-performance computing or server environments.

Environmental Factors to Consider When Selecting Materials

Environmental factors also play a key role in the material selection process for 6-layer SSD PCBs. With growing concerns about e-waste and energy efficiency, manufacturers focus on environmentally friendly and RoHS-compliant materials that do not contain hazardous substances such as lead, cadmium, and mercury. Lead-free solder and halogen-free laminates are becoming more common in 6-layer SSD PCBs, and these materials help ensure that 6-layer SSD PCBs meet global environmental standards while maintaining high performance and reliability, making the audience feel that the industry is moving towards sustainability.

In addition, PCB manufacturers are working to improve the recyclability of materials used in SSD designs, which helps achieve long-term sustainability goals. Selecting environmentally friendly materials is not only for compliance but also to ensure that manufacturers contribute to a greener and more sustainable future.

Material Selection’s Impact on 6-Layer SSD PCB Performance

Choosing the right materials for a 6-layer SSD PCB is critical to ensuring the board performs as expected in high-speed, high-density applications. From choosing FR4 as the base material to high-performance laminates, copper, and eco-friendly finishes, each material choice affects the board’s reliability, speed, heat dissipation, and overall functionality. As SSD technology advances, the materials used in 6-layer SSD PCBs will continue to improve, providing greater functionality, higher speeds, and better thermal management.